Stamping

From DDL Wiki

Process

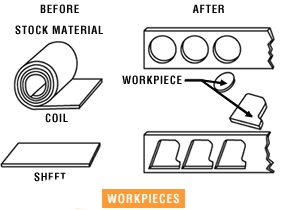

Stamping is the manufacturing process by which sheet metal is deformed via a die and punch into a desired shape. It is a very versatile process capable of many different form operations such as:

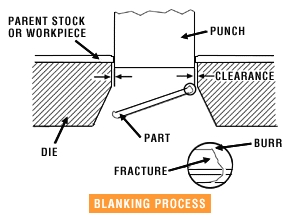

Blanking

The process by which a punch and die apply pressure to sheet metal to shear it and obtain a desired shape (blank) that is removed from the sheet which is now considered scrap.

Punching

The same process as blanking, except that removed material is scrap, and the remaining sheet is the workpiece.

Deep drawing

The process by which a sheet metal blank is formed into a cylindrical or box-shaped part by the punch pressing the blank into the die cavity.

Ironing

The same process as deep drawing, except that the die cavity has less clearance forcing the resulting cup to have a constant wall thickness.

Embossing

Bending

Flanging

Coining

Capabilities

Use

Simple or complex shapes at high production rates

Cost

High tooling and equipment costs

Low labor costs

References

1. http://en.wikipedia.org/wiki/Stamping_%28metalworking%29

2. http://www.beststampings.com/index.htm

3. http://www.engineersedge.com/manufacturing/metal_stamping.htm

4. http://www.mfgquote.com/process_metal_stamping.cfm

5. http://www.visionsenterprises.com/mastertool/definitions.htm