Steering rack

From DDL Wiki

| Line 78: | Line 78: | ||

The model can take into account the different impacts on Manufacturing, Transportation, Use and End-Of-Life. For our application of the Steering Rack, we only considered the environmental impact of the manufacturing phase because the vast majority of impact occurs then. In terms of transportation, the steering rack is relatively lightweight object that only gets transported once between sectors in its lifetime. From the aluminum and steel manufacturer to the machine shop to the end user. This product does not require heavy transportation nor continuous transportation. Therefore, we decided to neglect the transportation sector. In terms of use, there is no complimentary products or energy to maintain and keep the steering rack functional besides negligible amounts of oil and grease. Finally, End-Of-Life was neglected due to the fact that after the steering rack and ultimately, the car, have served their purpose, they either get disassembled and recycled for part re-use or educational function for young engineers or the cars get sold complete to interested alumni. Therefor, End-Of-Life considerations are minimal. | The model can take into account the different impacts on Manufacturing, Transportation, Use and End-Of-Life. For our application of the Steering Rack, we only considered the environmental impact of the manufacturing phase because the vast majority of impact occurs then. In terms of transportation, the steering rack is relatively lightweight object that only gets transported once between sectors in its lifetime. From the aluminum and steel manufacturer to the machine shop to the end user. This product does not require heavy transportation nor continuous transportation. Therefore, we decided to neglect the transportation sector. In terms of use, there is no complimentary products or energy to maintain and keep the steering rack functional besides negligible amounts of oil and grease. Finally, End-Of-Life was neglected due to the fact that after the steering rack and ultimately, the car, have served their purpose, they either get disassembled and recycled for part re-use or educational function for young engineers or the cars get sold complete to interested alumni. Therefor, End-Of-Life considerations are minimal. | ||

| - | ''' | + | '''Part 1: Motor Vehicle Parts Manufacturing''' |

In the EIO-LCA, Steering racks fall under the category "Motor Vehicle Parts Manufacturing." More specifically, a steering rack in sector 336330: Motor Vehicle Steering and Suspension Components Manufacturing. Note: all of the following figures and numbers are based on a $1 million worth of products. | In the EIO-LCA, Steering racks fall under the category "Motor Vehicle Parts Manufacturing." More specifically, a steering rack in sector 336330: Motor Vehicle Steering and Suspension Components Manufacturing. Note: all of the following figures and numbers are based on a $1 million worth of products. | ||

| Line 100: | Line 100: | ||

Figure #: Composition of Motor Vehicle Parts Manufacturing Category, by percentage | Figure #: Composition of Motor Vehicle Parts Manufacturing Category, by percentage | ||

| + | |||

| + | |||

| + | '''Part 2: Motor Vehicle Parts Manufacturing - Part by Part''' | ||

| + | |||

| + | Because of the high amount of aluminum in our steering rack compared to most steering racks and the rest of the category, we decided the break down the product into more detailed impact sectors. This is how it was broken down: | ||

| + | |||

| + | 1. ''Aluminum Extruded Manufacturing'': This category takes into account raw materials and extruded aluminum pieces that contribute to the Pinch Guard, Rack, and Extension. | ||

| + | 2. ''Iron and Steel Forging'': This category takes into account the raw materials for the pinion, set screw, and bolts. | ||

| + | 3. ''Machine Shop'': This category takes into account the final machining that must be completed for the product to function. This includes work to the exteneions, clevis, rack, extension, retaining block, and pinion. | ||

| + | |||

| + | Note: The raw material used to create the retaining block is not reflected in this analysis due to its minor differences from the extruded aluminum category. | ||

| + | |||

| + | To properly estimate the evironmental effect of each sector, estimations were made as to how much capital was spent in each sector to make the final product, which sells for $291.61. The estimations and final calculations are shown in figure #, at the bottom of the section. | ||

Revision as of 21:31, 20 September 2009

Contents |

Functionality

The steering rack produces linear motion from an applied torque to the pinion. The teeth on the pinion engage those on the rack which translates linearly between two bushings. The rack has extensions and clevises to reach the tie rods on the chassis which in turn rotate the wheel, thus steering the car. The pinion is designed to attached to a steering wheel so that the driver need not grip and turn the pinion directly, as they would be able to produce little torque.

Usability Study

Bill Of Materials

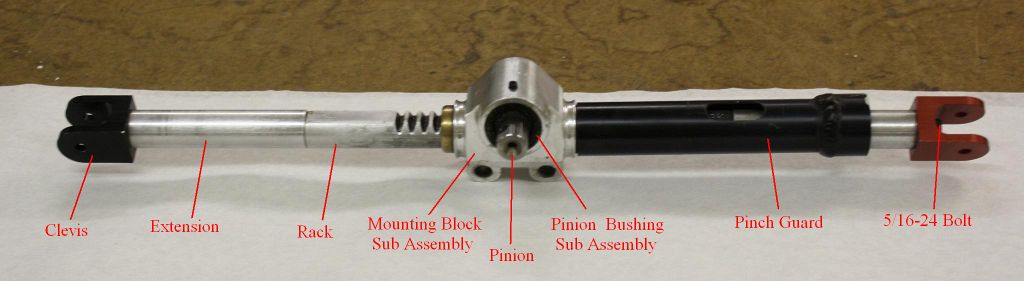

Figure 1: Steering Rack Sub Assembly

This assembly was originally a stock Prowerks Aluminum Steering Rack altered by Carnegie Mellon's Formula Society of Automotive Engineers to better fit an FSAE race car. We then disassembled their altered steering rack into its individual components and sub-assembilies. The components, and some basic information about each one, are listed below.

` *Sub-Assembilies were not deconstructed further. It was decided that doing so would result in the destruction of some components with little or no knowledge gained.

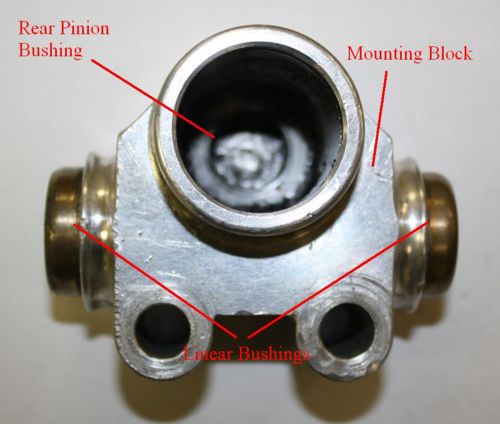

Figure 1: Retaining Block sub-assembly with components labeled.

Figure 2: Pinion Bushing sub-assembly with components labeled.

Design for Environment (DFE)

Designing a product for minimal environmental impact is a vital component a professional engineer must consider. The ASME Code of ethics says the following in Canon #8 regarding environmental impact:

"Engineers shall consider environmental impact and sustainable development in the performance of their professional duties."

To understand the full impact on the environment our product will create, an Economic Input-Output Life Cycle Assessment (EIO-LCA) was completed. The EIO-LCA takes into account Manufacturing, Transportation, Use and End-Of-Life. eiolca.net was utilized to create out EIO-LCA for the steering rack. The tool took information for the 1997 Industry Benchmark US Department of Commerce EIO Model and calculated many different parameters of interest.

The model can take into account the different impacts on Manufacturing, Transportation, Use and End-Of-Life. For our application of the Steering Rack, we only considered the environmental impact of the manufacturing phase because the vast majority of impact occurs then. In terms of transportation, the steering rack is relatively lightweight object that only gets transported once between sectors in its lifetime. From the aluminum and steel manufacturer to the machine shop to the end user. This product does not require heavy transportation nor continuous transportation. Therefore, we decided to neglect the transportation sector. In terms of use, there is no complimentary products or energy to maintain and keep the steering rack functional besides negligible amounts of oil and grease. Finally, End-Of-Life was neglected due to the fact that after the steering rack and ultimately, the car, have served their purpose, they either get disassembled and recycled for part re-use or educational function for young engineers or the cars get sold complete to interested alumni. Therefor, End-Of-Life considerations are minimal.

Part 1: Motor Vehicle Parts Manufacturing

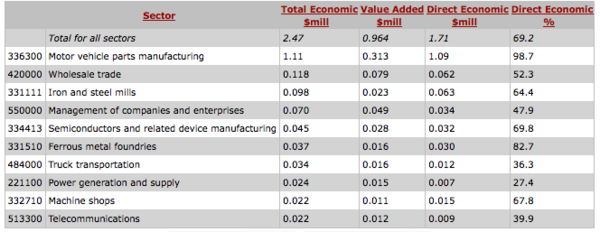

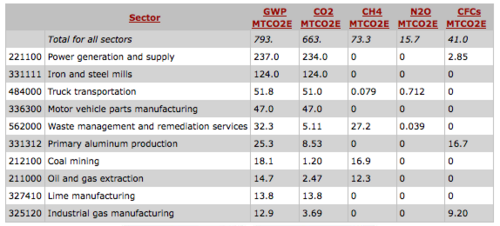

In the EIO-LCA, Steering racks fall under the category "Motor Vehicle Parts Manufacturing." More specifically, a steering rack in sector 336330: Motor Vehicle Steering and Suspension Components Manufacturing. Note: all of the following figures and numbers are based on a $1 million worth of products.

Figure #: Economic Activity in the Motor Vehicle Parts Manufacturing Category, based on $1 Million

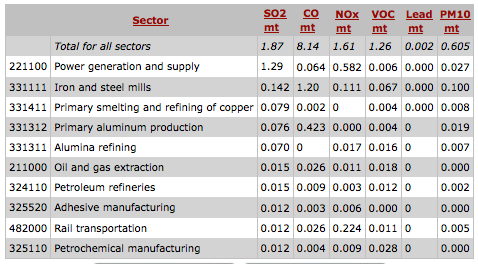

Figure #: Conventional Air Pollutants in the Motor Vehicle Parts Manufacturing Category, based on $1 Million

Figure #: Greenhouse Gases in the Motor Vehicle Parts Manufacturing Category, based on $1 Million

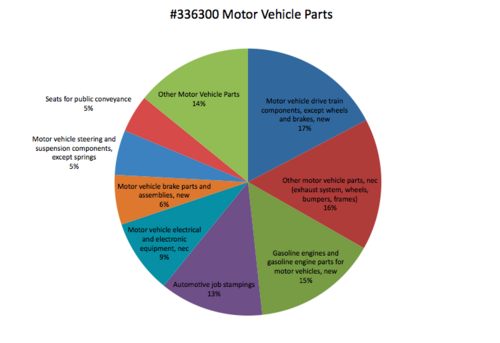

On all of these figures, Iron and Steel Mills makes up a considerable percentage of all emissions, much more than aluminum. If you look at the bill of materials, you notice that only 1 major component and 2 minor components are made up of steel, while the majority of the remaining components are aluminum. Because of this, and the fact sector 336330: Motor Vehicle steering and suspension components only make up 5% of the Motor Vehicle Parts Manufacturing category. This is shown in figure #:

Figure #: Composition of Motor Vehicle Parts Manufacturing Category, by percentage

Part 2: Motor Vehicle Parts Manufacturing - Part by Part

Because of the high amount of aluminum in our steering rack compared to most steering racks and the rest of the category, we decided the break down the product into more detailed impact sectors. This is how it was broken down:

1. Aluminum Extruded Manufacturing: This category takes into account raw materials and extruded aluminum pieces that contribute to the Pinch Guard, Rack, and Extension. 2. Iron and Steel Forging: This category takes into account the raw materials for the pinion, set screw, and bolts. 3. Machine Shop: This category takes into account the final machining that must be completed for the product to function. This includes work to the exteneions, clevis, rack, extension, retaining block, and pinion.

Note: The raw material used to create the retaining block is not reflected in this analysis due to its minor differences from the extruded aluminum category.

To properly estimate the evironmental effect of each sector, estimations were made as to how much capital was spent in each sector to make the final product, which sells for $291.61. The estimations and final calculations are shown in figure #, at the bottom of the section.