Steering rack

From DDL Wiki

Functionality

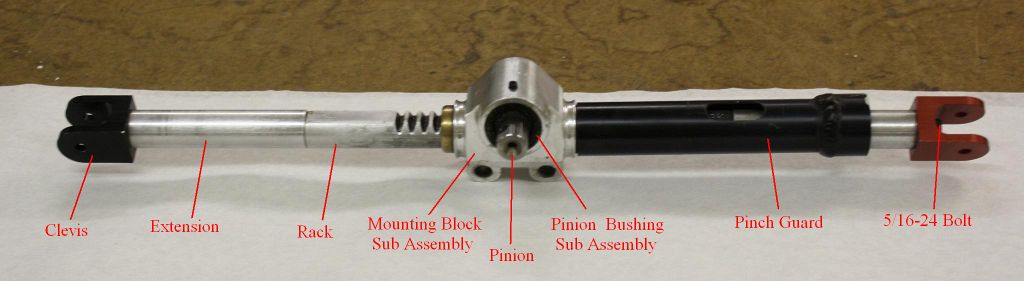

The steering rack produces linear motion from an applied torque to the pinion. The teeth on the pinion engage those on the rack which translates linearly between two bushings. The rack has extensions and clevises to reach the tie rods on the chassis which in turn rotate the wheel, thus steering the car. The pinion is designed to attached to a steering wheel so that the driver need not grip and turn the pinion directly, as they would be able to produce little torque.

Bill Of Materials

Figure 1: Steering Rack Sub Assembly

This assembly was originally a stock Prowerks Aluminum Steering Rack altered by Carnegie Mellon's Formula Society of Automotive Engineers to better fit an FSAE race car. We then disassembled their altered steering rack into its individual components and sub-assembilies. The components, and some basic information about each one, are listed below.

` *Sub-Assembilies were not deconstructed further. It was decided that doing so would result in the destruction of some components with little or no knowledge gained.

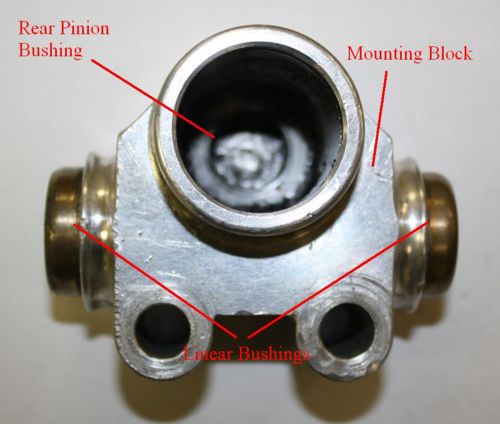

Figure 1: Retaining Block sub-assembly with components labeled.

Figure 2: Pinion Bushing sub-assembly with components labeled.

Design for Environment (DFE)

Designing a product for minimal environmental impact is a vital component a professional engineer must consider. The ASME Code of ethics says the following in Canon #8 regarding environmental impact:

"Engineers shall consider environmental impact and sustainable development in the performance of their professional duties."

To understand the full impact on the environment our product will create, an Economic Input-Output Life Cycle Assessment (EIO-LCA) was completed. The EIO-LCA takes into account Manufacturing, Transportation, Use and End-Of-Life. eiolca.net was utilized to create out EIO-LCA for the steering rack. The tool took information for the 1997 Industry Benchmark US Department of Commerce EIO Model and calculated many different parameters of interest.