Stethoscope

From DDL Wiki

(→Headset) |

(→Production Stage) |

||

| Line 363: | Line 363: | ||

=== Production Stage === | === Production Stage === | ||

| + | |||

| + | [[Image:Other plastics product manufacturing, table.png]] | ||

=== End of Life === | === End of Life === | ||

Revision as of 17:38, 11 February 2012

Contents |

Group Information

24-441 Spring 2012, Group 3

Resident Hawaiian: Kellen Chow

Live-saving Extraordinaire: Jacob Divone

Community Ass-Kicker (CA): KinHang Leung

International Covert Operative: Cecily Sunday

Project Executive Summary

A stethoscope is a medical device used for listening to internal body sounds. Our team is assessing the usability of a typical stethoscope used for medical applications. We will be studying the history of the stethoscope design to help determine how the product works. We will also be dissecting a stethoscope to study the construction and materials used in the assembly. We conducted a preliminary user study to develop ideas for improvement as well as features to consider during product dissection.

Competitor Product Analysis

Product History

The first stethoscope was invented in 1816 and it has been an essential tool in medical diagnostic methods ever since. René Laennec of France first came up with the idea of a stethoscope when he examined a patient using a stack of paper rolled into a cylinder. The first stethoscope was simply made of wood. In 1852, the design of a binaural stethoscope was introduced and the new prototype replaced wood with rubber making it more flexible and comfortable to use. In 1865, a more sophisticated stethoscope was designed with ivory, steel and wood. In 1870, the design of stethoscope became standardized as binaural and was manufactured with steel, rubber and cotton for quality and durability. In 1998, the modern binaural stethoscope was invented and manufactured using stainless steel, rubber, nylon and plastic.

Product Functionality and Use

Three main components allow the acoustic stethoscope to transmit sound: a chest piece, an air filled tube, and a headset. In this medical device, vibrations are used to create pressure waves which travel from the source to the listener via air trapped in a hollow tube. While several design variations of the stethoscope exist, the theory behind each model remains the same.

PICTUREs OF STEM

The chest piece is responsible for capturing vibrations on a surface. Most chest pieces consist of a diaphragm or a plastic disk that vibrates in response to the surface sound. As the diaphragm vibrates, an acoustic pressure wave is created in the hollow interior of the chest piece. This pressure wave then travels through an air filled tube to the ear buds at the end of the headset where the sound reaches the listener. Many stethoscopes also have a bell, or an inverted cup situated opposite of the diaphragm. In contrast to the diaphragm, the bell creates pressure waves from the vibrations of the skin itself. The diaphragm is used to transmit higher frequencies while the bell transmits lower ones.

The stethoscope depicted in Figure 1 has two diaphragms located on the chest piece as opposed to a diaphragm and a bell. However, the smaller diaphragm functions the same as the bell because it is used to hear lower frequencies. The front, clear plastic side of either diaphragm is meant to be placed on the surface while the backs are to be screw into the stem, or the metal component that connects the chest piece to the tubing (see Figure 2). Before using the stethoscope, the chest piece must be indexed, or turned appropriately so that airflow is directed through the correct path. Airflow is directed through a valve located in the stem.

PICTURES OF DIAPHRAGM AND STEM

The acoustics of the stethoscope will be affected if the path from the diaphragm to the headset is not airtight. Obstructions in its interior from dirt or related build-up will also affect the sounds quality of the stethoscope. For these reasons, frequent cleaning and maintenance is required to insure the stethoscope continues to function properly.

Preliminary Product User Study

Our group conducted a preliminary study to determine the proper use of the stethoscope. This medical device is used in a variety of settings, each with varying degrees of background sound and activity. Both in the field and office settings, the stethoscope is used to assess heart sounds, lung sounds, and blood pressure. This can be done by applying the diaphragm or bell to the chest, back, or inner arm (below the blood pressure cuff) depending on what assessment is desired. User studies are essential to help determine what problems exists with the functionality and use of this product.

Step-by-step User Instructions

Observations from Preliminary User Study

(1) Hard to hear in loud environments

(2) Extra noise created if the chest piece slides along the surface

(3) Headphones are uncomfortable to wear

(4) Acoustics may be affected by loose parts or obstructions in the air path

(5) The quality of sound is likely to be affected by the following parameters: diameter, length, and material of tube, vibration medium (air vs. water), material and shape of the ear buds, single vs. double connecting tube

(6) Adding a visual representation of the frequency, input signal, etc. ?

Product Disassembly

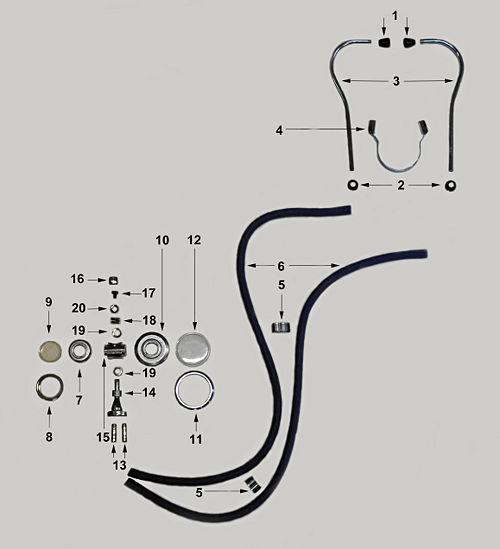

The stethoscope can be broken down into 3 major components: Headset, Air-filled Tubes, Chest Piece

Headset

Picture of just the headset

- The Earbuds can be unscrewed from the Eartubes easily. (Design for easy replacement or customization)

- The Eartube Caps has to be removed by force and then the headset can be separated from the tubes.

- The Triple-Leaf Spring and the Eartube Caps can then be easily slid off the Eartubes.

Air-filled Tubes

Picture of just the rubber tubes and the clamps

Chest Piece

Picture of just the chest piece (still assembled)

Bill of Materials

- ABS: Determined by deduction; it sinks in water (SG > 1.0), medium hardness, opaque, non-brittle, low-cost manufactured

- PE: Determined by deduction; it floats in water (SG < 1.0), ductile, transparent, non-brittle, low-cost manufactured

Failure Mode Effects Analysis (FMEA)

This is the FMEA. It's going to rock.

| Part | Part Function | Failure Mode | Failure Effects | Severity | Cause(s) of Failure | Occurence | Detection | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|

| Low Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm is punctured | Loss of stethoscope functionality | 5 | Impact Fracture | 3 | 3 | 45 | Inspect stethoscope before each use |

| Low Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm surface is scratched | Reduced sound quality and functionality | 3 | Surface fatigue wear | 3 | 2 | 30 | Inspect stethoscope before each use |

| Low Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm surface is warped | Reduced sound quality and functionality | 4 | Thermal/surface fatigue | 2 | 3 | 24 | Inspect stethoscope

before each use |

| High Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm is punctured | Loss of stethoscope functionality | 5 | Impact Fracture | 3 | 3 | 45 | Inspect stethoscope before each use |

| High Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm surface is scratched | Reduced sound quality and functionality | 3 | Surface fatigue wear | 3 | 2 | 30 | Inspect stethoscope before each use |

| High Frequency Diaphragm | Changes pressure in stethoscope to detect sounds | Diaphragm surface is warped | Reduced sound quality and functionality | 4 | Thermal/surface fatigue | 2 | 3 | 24 | Inspect stethoscope

before each use |

| Binaural Eartube | Translates sound to eartips | Eartube bent | Reduced sound quality and functionality | 2 | Yielding | 2 | 2 | 8 | Inspect stethoscope before each use |

| Eartips | Sits in ear canal, translates sounds | Eartips are scratched or deformed | User discomfort | 5 | Surface fatigue wear | 2 | 3 | 30 | Inspect eartips before each use |

| Rubber Tube | Translates sounds from stem to eartubes | Rubber tube is corroded | Reduced/loss of functionality | 5 | Impact/surface fatigue wear | 4 | 3 | 60 | Inspect tubes before each use |

| Triple-Leaf Spring | Stablize and maintain tension in eartubes | Spring is deformed | User discomfort, lack of tension in eartubes | 3 | High-cycle fatigue | 5 | 2 | 30 | Inspect spring before each use, perform fatigue tests after manufacturing |

| Tube Clamp | Keeps rubber tubes together | Tube clamp can deform, causing the rubber tubes to fall out | Minor inconvenience when tubes are loose | 2 | High-cycle fatigue | 2 | 2 | 8 | Inspect tube clamp before each use, run high-cycle fatigue tests after manufacturing |

| Tube Pins | Connects rubber tubes to chestpiece | Tube pins can fracture, leaving the rubber tubes with nothing to connect to | Loss of functionality | 6 | Brittle fracture | 2 | 2 | 24 | Inspect tube clamp before each use, run high-cycle fatigue tests after manufacturing |

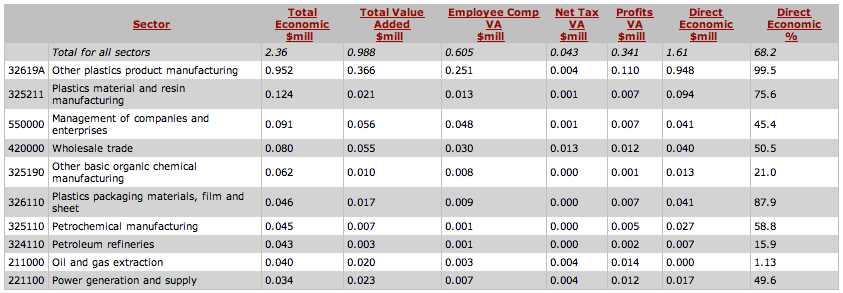

Design for Environment (DFE)

There are many other versions of stethoscope in today's market, some with additional features including electronic amplifier and monitors. Although our dissected stethoscope lack the fancy features, it is designed to consume zero energy in the Use Phase while minimizing the environmental impact in the Production Stage. Our only concern with its environmental impact is the choice of rubber material for the tubes and the amount of specialized machining required on certain parts. As shown below, we have utilized the EIO-LCA tool from the Carnegie Mellon website.