Tie rack calculations

From DDL Wiki

m (Tie rack calculations and fbd moved to Tie rack calculations) |

Revision as of 18:47, 5 March 2007

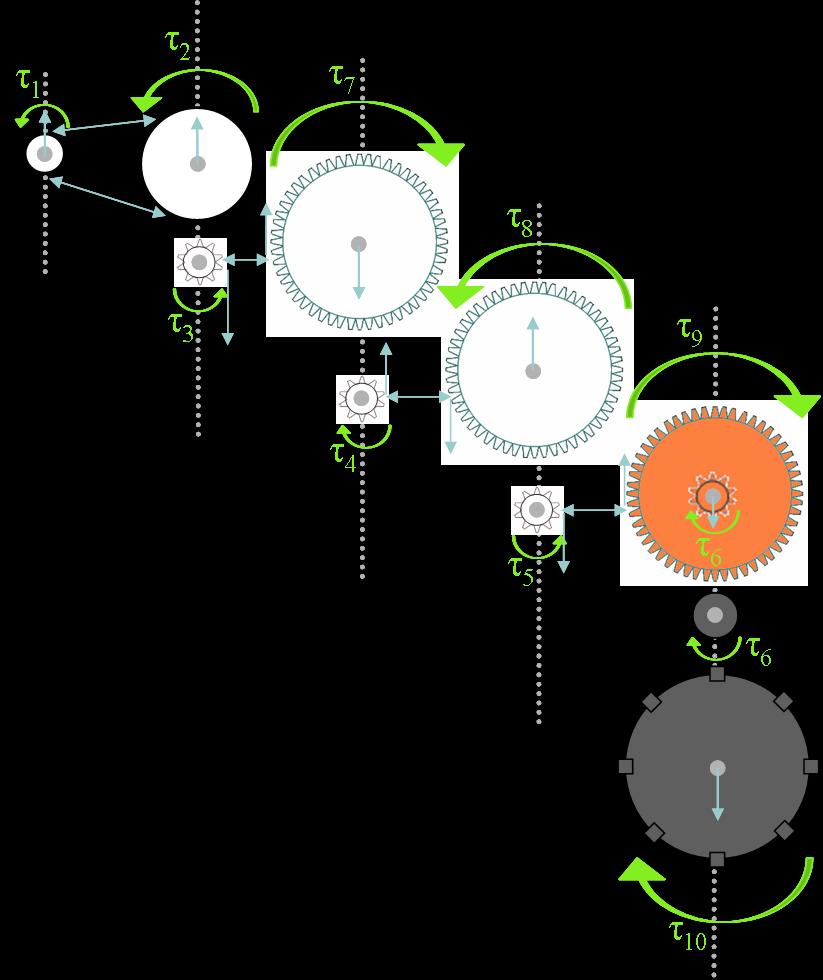

Gear Train

Summary:

The values below were calculated using the following analysis. They show that the gear train in the rotating tie rack is used to decrease speed and increase torque provided by the motor.

Motor Speed: ω1 = 51314.84 RPM

Motor Torque: τ1 = 0.0284 N-m

Output Speed: ω10 = 70.26 RPM

Output Torque: τ10 = 138.28 N-m

Speed of Output

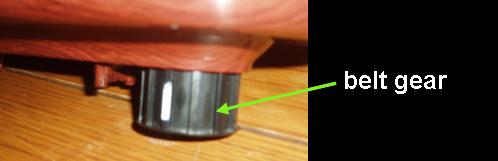

The gear train creates a decrease of speed and increase of torque from the actual motor output. The final speed is slow enough to measure with a stopwatch. This was done by marking a point on the rotating belt, and measuring the time that it took for one rotation (the point returns to where it started).

Setup:

Time for one rotation of belt gear = 5s : 38ms Circumference of belt gear = 0.126 m

Speed = length/time (m/s)

Angular speed = ω = 2π/T (radians/s)

ω10 = length / [r10 * time] = (0.126 m) / [(0.02m)(5.38 s)] = 1.17 rotations/sec

ω10 = 70.26 RPM

Gear Ratios/Calculations (Relating input to output)

ω1 r1 = ω2 r2 and ω2 = ω3

ω2 = ω4 = [r1 / r2] ω1 (1)

ω3 r3 = ω7 r7 and ω7 = ω4

ω7 = ω3 = [r3 / r7] ω3 (2)

substitute (1) into (2)

ω7 = ω4 = [r3 r1 / r7 r2] ω1 (3)

ω4 r4 = ω8 r8 and ω8 = ω5

ω8 = ω5 = [r4 / r8] ω34 (4)

substitute (3) into (4)

ω3 = ω5 = [r4 r3 r1 / r8 r7 r2] ω1 (5)

ω5 r5 = ω9 r9 and ω9 = ω6

ω9 = ω6 = [r5 / r9] ω5 (6)

substitute (5) into (6)

ω9 = ω6 = [r5 r4 r3 r1 / r9 r8 r7 r2] ω1 (7)

substitute ω10 = ω6 into (7)

ω10 = [r5 r4 r3 r1 / r9 r8 r7 r2] ω1 (8)

ω10/ ω1 = [r5 r4 r3 r1 / r9 r8 r7 r2] (9)

ω1/ ω10 = [r9 r8 r7 r2 / r5 r4 r3 r1] (10)

ω1 = [(0.019m)( 0.019m)(0.019m)(0.0115m) / (0.003m)(0.003m)

(0.003m)(0.004m)] * 70.26 RPM

ω1 = 51314.84 RPM = motor speed

Stall Torque

The stall torque of the motor was calculated by finding an equilibrium point between an opposing torque and motor output torque. This was done by turning the motor sideways, powering it, and hanging weights on the pulley attached to the motor shaft until weight suspension was reached (τ1 = τ2). The string is of negligible mass and was tightly affixed to the pulley to prevent slipping by both knotting it with a rubber band.

Setup:

Result:

Motor stalled when 0.8 lb weight was creating a torque. Thus:

0.8 lbs = 0.363 kg

Radius of motor pulley = 0.004 m

τs = Fr = (0.363 kg) (9.81 m/s2) (0.004 m)

τs = 0.0142 Nm = 14.24 mN-m

Engine Torque

A relationship between torque and speed can provide an equation to calculate the torque output from the motor when it runs in the device. Assuming ideal motor function, thus a linear distribution:

τ = α ω + τs

α = τs / speed = 0.0142 mN-m / 51314.84 RPM = 2.77 x 10-7

τ1 = α ω1 + τs = (2.77 x 10-7) (51314.84 RPM) + 0.0142 N-m

τ1 = 0.0284 N-m = motor torque while running

Applying Torque ratios:

τ6 = (ω1/ ω6) τ1

τ10 = (r10 / r6 )*(ω1/ ω6)* τ1

τ10 = (0.02m/0.003m)*( 51314.84 RPM / 70.26 RPM) * 0.0284 N-m

τ10 = 138.28 N-m = output torque