Weed whacker analysis

From DDL Wiki

(→Design) |

(→Design) |

||

| Line 31: | Line 31: | ||

==Design== | ==Design== | ||

| - | + | <big>Redesigned Troybilt Model</big><br /> | |

| + | 2-cycle gas motor moved to backpack<br /> | ||

Our design was meant to eliminate the trade-off between weight and handling. With the new placement of the handles and removing excess weight, our design improves both the weight as well as the inertia to reduce the work needed from the user to operate efficiently. | Our design was meant to eliminate the trade-off between weight and handling. With the new placement of the handles and removing excess weight, our design improves both the weight as well as the inertia to reduce the work needed from the user to operate efficiently. | ||

Revision as of 12:40, 10 November 2008

Contents |

Summary

Mass/Inertia Comparison

Electric

Black and Decker Model

Electric motor

Weight: ~7.0 lbs

Center of Mass: ~35 inches from the center of trigger handle

Inertia about trigger handle: ~6500 lb in^2

Compared to the other models, the inertia is significantly higher. It is over twice the inertia than the gas powered design. The benefit to this design is that overall, it is 60% of the weight of the gas powered design.

Original

Troybilt Model

2-cycle gas motor

Weight: ~11.5 lbs

Center of Mass: ~0 inches from center of trigger handle

Inertia about trigger handle: ~2679 lbs in^2

The benefit of this model over the electric design is that the mass is better balanced, making it easier to handle. However the weight is 50% more.

Design

Redesigned Troybilt Model

2-cycle gas motor moved to backpack

Our design was meant to eliminate the trade-off between weight and handling. With the new placement of the handles and removing excess weight, our design improves both the weight as well as the inertia to reduce the work needed from the user to operate efficiently.

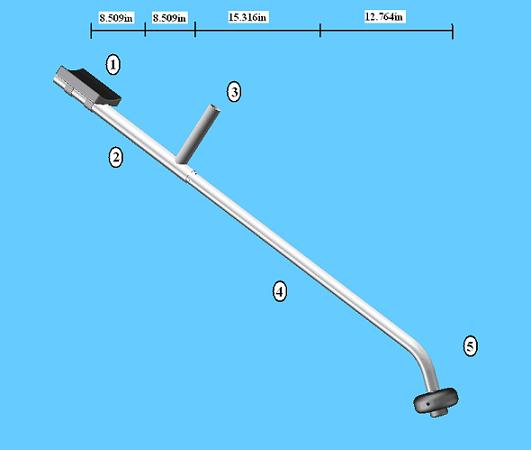

1) Elbow plate

• Weight = ~1 lb

2) Upper shaft, torsion cable

• Weight = ~.963 lb

3) Handle, trigger

• Weight = ~.229 lb

4) Lower shaft, torsion cable

• Weight = ~1.069 lb

5) Shield, weed whacker upper head, weed whacker lower head, spring, bearing, bump knob, wire

• Weight = ~1.080 lb

Assumptions:

• Point masses

• Weed whacker is held at approximately a 45° angle

Weight: ~4.3 lbs (est.) with ~6.5 lbs on back

Center of Mass: ~ 32 inches from elbow plate

Inertia about elbow plate: ~1720 lbs in^2

This mechanical analysis shows the significant change in both mass and inertia our new design has in relation to the original weed whacker. Specifically, the new design’s inertia is 64% of the original. This also means that the energy required to sweep the trimmer one foot is 64% of the original as well. The ease of use is a major concern in our design process, and these numbers show that our new model takes a big step in the right direction. These numbers are also important in considering the new way the trimmer will be held. Although the trimmer will now only be held with one hand, the majority of the weight will be held up by the straps around the forearm. The trimmer originally weighed 11 lbs. Now it weighs just over 4 lbs. The combination of weighing less than half the original weight and the additional support given by the forearm gives us confidence that the user will feel much less strain from our new design. The combination of the lower inertia and the forearm support shows how much easier it will be to use our product. The user will now have significantly more control when moving the trimmer from side to side. The old design required coordination between both hands, and its weight and inertia made it awkward and clumsy. The one-handed design allows the user to control the trimmer with the very simple movements of his arm. This improvement in ease of use allows the user to both trim more efficiently as well as more accurately.

Conclusion

Cost

Gas

To analyze the projected cost of our gas powered weed whacker model, we estimated the cost of a standard 31cc 2 stroke engine, and factored in the ongoing cost of fuel and oil. We found the cost of a standard 31cc 2 stroke engine to be approximately 30$. For fuel costs, we found the energy in regular unleaded gasoline is 125,000 Btu/gallon. With the average price of regular unleaded gasoline in the U.S. being 2.4 $/gallon, you get 52083.3 Btu/$.

Electric

To analyaze the projected cost of our electric weedwhacker model, we calculated the estimated cost of an appropriate battery to utilize as the power source. Based on our user study of the Black and Decker electric weed whacker, we know these characteristics:

•18V

•1.2 AmpHours

•~45 minutes of effective use time

For our electric model, we want to achieve an effective use time of 3 hours, therefore we chose to use an 18V battery with a charge of 4.8 AmpHours. With our known voltage and charge, we can calculate the amount of Watt-Hours used by our battery:

18V * 4.8AmpHours = 86.4 Watt-Hours

Knowing the energy use of our battery, we can calculate the cost of this battery. We found that different types of batteries have different energy costs. For example, the battery used for the Black and Decker weed whacker is Nickel Cadmium, which has an energy cost of 1.50 $/WattHour, while a Lead Acid battery, such as a car battery, only has an energy cost of 0.17 $/WattHour. Because of this, we chose to use a Lead Acid battery. It would be bigger, much like a car battery, but having the battery in a backpack much like our first prototype is no heavier than the original 2 stroke engine used in the first prototype. The cost of this Lead Acid battery would simply be:

(86.4 Watt-Hours)*(0.17 $/Watt-Hour) = 14.68 $

Of course the battery would cost a bit more than this because we would be manufacturing a custom battery with 18V and 4.8 AmpHour charge.