Spray deposition

From DDL Wiki

Contents |

Spray Deposition

Spray it, Don't Say it

Purpose

Spray deposition is not a powder metallurgical process within the strict definition of that term since metal in actual powder form is not involved. It involves the atomisation of molten metal, but instead of being allowed to solidify as powder, the spray is collected on a substrate to form billets for subsequent forging.

Process

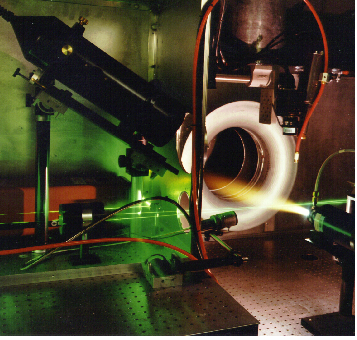

The most common method of spray deposition is gas assisted spray forming. In gas assisted spray forming, high pressure high velocity inert gas jets are used to both atomise the melt stream and direct the resultant flow of semi-molten metal droplets onto the surface of a substrate or collector which is manipulated in order to allow the controlled build-up of deposit or preform shape.

Materials

The range of materials that are being processed in this way is extremely wide and includes Al alloys, Cu alloys, stainless steels, high Cr alloy steels, and superalloys.

Shapes

The range of shapes is extensive also; - round billets, tubes, strip and sheet, and near-net shape pre-forms. Clad materials are also being produced, for example low alloy steel rolls clad with high speed steel. The sizes that can be produced are, naturally, a function of the available plant and they are continually rising. A recent installation will produce tube blanks weighing up to 4.5t.

Advantages of Spray Deposition

With conventional products such as, for example, stainless steel tubing, the benefit of spray deposition is mainly cost saving, in other cases there are significant property improvements. Rolls for metal rolling mills spray-deposited and HIPped have been found to have 2 or 3 times the life of cast rolls of similar composition.

Among the materials that cannot be made conventionally, but can be made by spray deposition, are rapidly solidified Al-Li alloys, Al-Sn alloys with high Zn content (11%), highly alloyed Cu-Ni-Sn and Cu-Cr, as well as the some metal matrix compositions. In this last case, the reinforcing particles are injected into the metal stream during the atomisation process. Spray deposition seems destined to have a very interesting future.

References:

http://www.azom.com/details.asp?ArticleID=1653

http://www.irc.bham.ac.uk/theme1/atomisation/spray.htm

http://www.bu.edu/pcl/tour/plasma.html

Contributers: Gil Palmon, Rob Cavagnaro, Samantha Schultz, Alex "Busta" Malkin