Water gun

From DDL Wiki

Contents |

Executive Summary

The water gun has evolved from a simple pump and spray mechanism to a more complex motorized system. In this report, an extensive product analysis is done on the Saturator AK-47 water gun to gain some insight on how the product operates and possibilities for innovation. During our research we determined the major stakeholders of the product, the perspective of the designer, how the product was made, and its impact on the environment.

Analyses of the water gun model helped us understand what the needs are of the stakeholders. From the product dissection we concluded that there was emphasis placed on the manufacturing and assembly of the product; development of a cheap, easily manufactured and durable product. It seemed that the creators of the product needed to focus more on developing a water gun with an optimal design for the consumer as well as the manufacturers. Our research included a full product dissection to understand the manufacturing and assembly processes, failure modes and effects analysis and its effect on the environment.

In our initial stages of research we tested the Banzai Color Stream Blaster, a pressurized powered water gun and compared the user experience to that of the Saturator AK-47. While the Color Stream Blaster was a fun product it was decided that the Saturator AK-47 water gun had more room for innovation. We discovered that many of the components of the Saturator AK-47 are injection molded thermoplastic and they are not only assembled but also glued together. The use of plastic is common for mass produced products. Another key finding within the FMEA analysis was valve reliability. Leakage was a concern especially for the Color Stream Blaster. After a detailed analysis using the EIO-LCA program we concluded that the Saturator AK-47 water gun is not an environmentally conscious design, because of the heavy use of plastic and use of batteries for power. In our re-design process we hope to put more emphasis on designing for the environment.

In conclusion, based on the results compiled from the different types of analyses we were able to pin point areas that should be considered in a re-design of the product such as the valve, minimizing the amount of noise and an environmentally riendly design. The Saturator AK-47 is a solid toy for its price and with some modification and innovation it has the potential to be a competing product in its market.

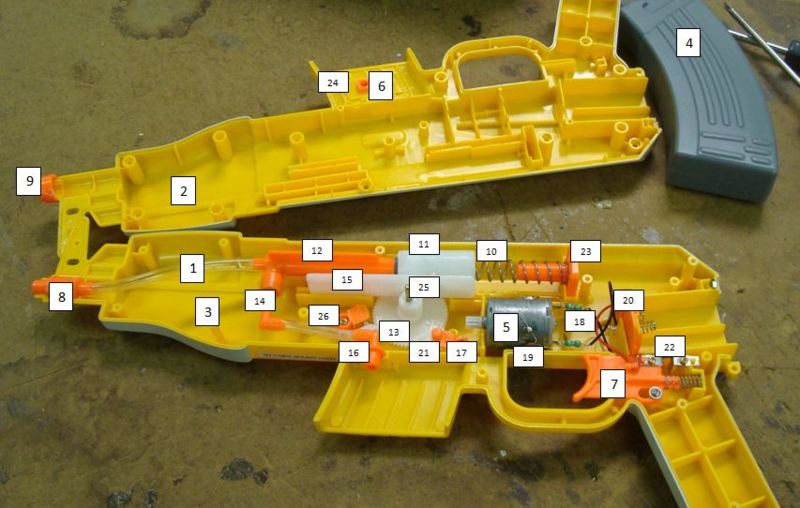

Bill of Materials

Main Components

Assembly

- Tube

- Shell side A

- Shell side B

- Reservoir

- Motor

- Reservoir release switch

- Trigger

- Nozzle

- Nozzle ring

- Spring

- Piston

- Piston housing

- Large spur gear with half gear

- Elbow valve

- Large axle

- Valve

- Gear retainer

- Resistor

- Capacitor

- Terminal holder

- Small spur gear

- Trigger contact bracket

- Pressure plate

- Retaining plate

- Large axle

- Ratchet retainer

Stakeholders

There are four primary stakeholders for the product: the consumer, retailer, manufacturer, and shipping/transportation of the product. The consumer can be broken down in to sub categories, buyer and user. The needs of each stakeholder are addressed in the following bullets.

Consumer

With relation to the Saturator water gun, there are two major consumers: adult (i.e parents) and the users -children and young adults. The needs and requirements of these two consumers are drastically different as shown below.

Buyer (Adults): Consumers are adults including young adults but our primary consumers are parents. Parents of the user will monitor the use of the product and their concerns will mainly be with safety. The needs of the adults are listed below:

- Low cost

- Safe

- Easy for child to use & store

- Durable

- Long product lifespan

- Non-threatening

- Non-toxic

User (Children): The users of the product are children and this categorey also include and are not limited to children over the age of 16. For the primary user the product needs are:

- Visually attractive

- Fun to play with

- Long range of shooting

- Quick & easy to refill

- Accurate & precise shooting

- Lightweight

- Easy to operate

Retailer

Retailers: Retailers are also stakeholders of the product. Their needs are as follows:

- Satisfying to customer

- Easy to shelve and store

- Easy to sell

- Durable

Manufacturer

Manufacturers: Manufacturers as stakeholders of the product have needs including but not limited to:

- Few parts & materials

- Minimize manufacturing processes

- Efficient assemble process

- Low cost production

- Standard parts across a range of models

Shipping/Transport

- Easy to stack

- Small & lightweight product

- Durable

Usage

How It's Used

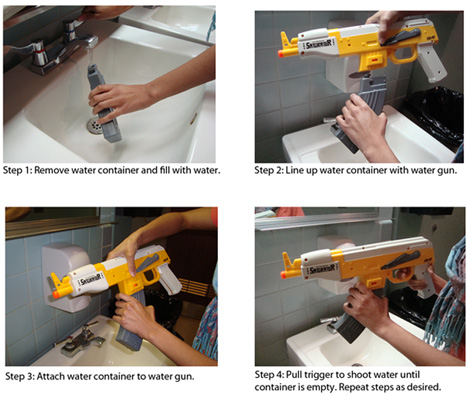

When initially removed from the packaging, the Saturator requires 4 AA batteries for operation (batteries not included). The batteries are inserted through the butt of the water gun. After battery insertion, the Saturator needs to be filled with water before it can be used. This process is described in the image below.

User Studies

Investigative processes include testing of two types of water guns, the Saturator AK-47 and the Banzai Color Stream Blaster Water Gun.

Saturator AK-47: Overall, the Saturator AK-47 Water Gun performs at the average standard for toy water guns. While the water container or clip stays in place, the gun needs to be refilled very often during play. Another negative aspect of this product is the range of shooting. Although it is advertised as a gun that can shoot over 25 feet, the stream of water barely makes it a distance of 15 feet.

Banzai Color Stream Blaster: The Banzai Color Stream Blaster is a pressurized gun. In our test we noticed that the product was quite messy. The Color Stream Blast pump system was futile after about 10 pumps, which was necessary for maximum performance. Althought the product manual explains that all that is needed for the water gun to shoot a continuous stream at a maximum distance of 30 feet was 3-4 pumps. In our studies we found that it took 8-10 almost triple the amount documented to get a continuous stream that reached a maximum distance of 20 feet. After testing the gun there was a puddle of water from the container that leaked during the testing. Pumping the water everytime we wanted to shoot proved to be tiring.

Comparison: The Saturator is the easiest to use and least messy which was preferred in our user study. The Banzai Color Stream Blaster is an interesting product because of the addition of the color cartridges. We did a product dissection of the color blaster to get understanding of how the toy works. We discovered that there was a lot of tubing inside the casing especially since it was a simple pump and spray mechanism. The Saturator had less tubing under the casing although its powering mechanism is more complex overall the studies showed that the AK-47 water gun has more potential for re-design and innovation.

Mechanical Function

Batteries are loaded into the compartment by opening the battery hatch, which is held closed by a small captive screw.

Water is loaded by unclipping magazine from bottom, by means of a sliding latch, then opening plug and filling. Magazine slots back into place, reengaging magazine feed tube with pump inlet tube.

Trigger pull acts differently than in other styles of water gun. Rather than opening a valve or directly actuating a pump directly, it, being an electric gun, closes the circuit to activate the motor.

The drive axis of the moter is changed via a crown gear, then goes through several gear reductions ending in a half-toothed gear. This drives a rack gear which is connected to the plunger of the pump cylinder. As the plunger is retracting, the expanding volume draws water in through the one-way valve connected to the feed tube, which draws water up from the magazine, while closing the valve in the nozzle. The piston is driven against a spring, and when the teeth of the half-gear disengage the spring is released, driving the piston back into the cylinder, closing the feed tube valve and driving the water out through the one-way valve in the nozzle. As the gear continues turning, the teeth reengage, beginning the cycle again. The motor itself never reverses direction during operation.

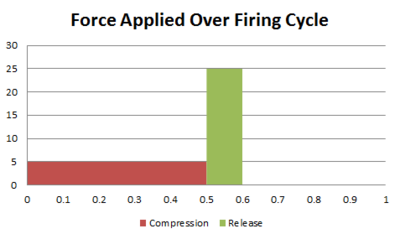

The force necessary to produce an effective stream is applied by the spring in a much shorter period of time than the mechanism takes to compress it, using it to store the energy for a pulsed output. This allows the use of a motor with much less power than if it were driving the firing portion of the action directly. As seen in the figure below, the areas under the curves are equal, implying equal work done in both phases (not technically accurate due to inefficiencies), but because the spring expends its energy in (here, for illustrative purposes) 1/5 of the time, it applies 5 times as much force.

Design for Manufacture & Assembly (DFMA)

The design of a product should always include the most efficient manufacturing and assembly method. In case of a water gun, it has one more requirement to fulfill—the prevention of any form of dissection. In other words, the product should be designed in a way that once it is assembled, the user cannot easily take the product apart due to the danger of choking hazard and the danger of modification of the product. Saturator AK-47 well achieves this requirement by tightly sealing almost every assembled region with adhesive. One negative aspect of Saturator AK-47 is that its assembly requires too much labor time considering the high volume of production, since every assembled joint has to be glued.

Majority of the parts of this product are produced by injection molding, which is ideal for producing high volumes of the same object. This product is composed of many small pieces that requires significant amount of labor time to assemble everything, but it does not have optimized number of pieces as shown in Figure 3.

The tube inside of the water reservoir is composed of four different pieces, while it could be substituted by two pieces: one plastic tube with a small hole on each end and one rubber ring tightening the space between the tube and the reservoir. This tubing sub-assembly could be processed by two injection moldings plus a very short labor time to attach the rubber ring to the tube, while the original tubing sub-assembly had to go through four injection moldings and extra labor time to plug and glue all four pieces together. This was just one example of the inefficient number of pieces that consumes significant amount of labor time. Another example is of an unnecessary piece is shown in Figure 4, which is the pressure plate.

Since its function is to simply hold the spring (used for piston movement), the same function can be performed by having an extruded plate coming out of the shell Side A during the process of injection molding. By optimizing the number of parts, we can shorten the assembly processing time, making a competing product much cheaper.

Failure Modes & Effects Analysis (FMEA)

Based on the FMEA table generated below, the highest priority in redesigning the product would be to creat a design with more even efficiency and power usage. The requirements of a design that uses direct piston power rather than a pressure tank dictate an asymmetric reciprocating movement which causes unnecessary stresses to the mechanism and produces an undesirable amount of noise. Opportunities for redesign could potentially focus on a quieter mechanism, by eliminating the unnecessary impact involved in the current one.

The second highest priority, ranked by RPN, is valve reliability. Multi-piece user serviceable valves, however, seem to run counter to the process of reducing the next most numerically significant failure point, leakage. Considering that valve failure is likely to be a rare problem, only ranked as highly as it is due to the sealed and unrepairable valves, it might not be worth prioritizing over the much more common and irritating problem of leakage.

Leakage is mostly noted at joints between components because of a lack of effective seal. The Color Stream Blaster attempted to solve this problem with application of glue over the joints, but even with this the gun leaked notably, staining the user's hands. While improving the quality of hose barbs, and including locking nuts over the joints, can improve the situation, there is an opportunity to be found in multi-part valves.

It is worth noting that most components have a one-way valve between them. Connecting components via a split in the valve chamber, if constructed well and sealed with an o-ring, could solve both problems together, and make production more flexible. Valve redesign would probably be necessary to support this, however, due to the increased accessibility of small parts, which would present a choking hazard to younger children

Numerical Ratings:

- S: Severity (1-3: Functionality/efficiency reduced, 4-6: Functionality interrupted, varying levels of repairability, 7-10: Potential danger to user)

- O: Frequency of occurrence (1: Extremely unlikely, 10: Inevitable and frequent)

- D: Detectability (1: Failure immediately apparent, 10: Failure undetectable)

| Item/System | Failure Mode | Effects of Failure | Causes of Failure | Design Changes | User Remedies | S | O | D | RPN |

|---|---|---|---|---|---|---|---|---|---|

| Motor/Circuit | Short Circuit | Inoperation (no motor), overheating, battery damage | Crossed wires/loose contacts | Limit wire movement caused by use, provide positive wire routing fixtures | Depending on damage, fix wiring or dispose of gun | 8 | 2 | 3 | 48 |

| Broken Circuit | Inoperation (no motor) | Broken wire/solder joint | Limit wire movement caused by use | Repair solder | 4 | 3 | 2 | 24 | |

| Trigger | Open Circuit | Inoperation (no motor) | Deformed Contact | Use more robust switch | Bend contact back | 4 | 3 | 2 | 24 |

| Tubing | Puncture | Leak during firing, reduced firing capacity | Damage to tube | None | Patch hole | 2 | 2 | 5 | 20 |

| Leaky connection | Leak during firing, reduced firing capacity | Insufficient seal at joint | Better tubing fixtures: longer hose barbs, locking rings. Sealant on joint. | Add sealant | 2 | 8 | 4 | 64 | |

| Reservoir | Crack | Constant leak | Physical abuse | Thicker material | Cover crack or replace part | 3 | 2 | 1 | 6 |

| Insufficient seal | Leak during firing, reduced firing capacity | Incomplete engagement | Decrease tolerance for tighter engagement | Add sealant, check socket for obstructions | 2 | 2 | 5 | 10 | |

| Gear Train | Jamming | Inoperation, or intermittent operation (motor slowing, no water) | Debris in gun body | None, body well closed/sealed | Open and clear debris | 4 | 2 | 6 | 21 |

| Broken teeth | Reduced firing capacity, possible jamming or complete inoperation | Stress of periodic disengagement/reengagement | Thicker gears, design that doesn't require disengagement | None | 4 | 3 | 8 | 96

| |

| Broken ratchet | Partial cylinder load ejected when firing ends | Stress of engagement | Larger gears/teeth to reduce overall stress | None | 1 | 2 | 8 | 16 | |

| Valves | Stuck open | Inoperation (no water) | Debris, misalignment, broken spring | Stronger spring, aligning features for plunger | None | 6 | 2 | 7 | 84 |

| Stuck closed | Inoperation (no water), possible leak during attempted firing | Debris or misalignment | Aligning features for plunger | None | 6 | 2 | 7 | 84 | |

| Pump Piston | Insufficient seal | Leak during firing, reduced firing capacity | Damage to o-ring, lack of lubricant | Additional redundant o-rings | Relubricate, replace o-ring | 2 | 3 | 6 | 36 |

| Shaft damage/breakage | Reduced firing capacity, possible inoperation | Stress due to misalignment | Alignment features for shaft, thicker cross-section | None | 3 | 1 | 3 | 9 | |

| Reservoir Release | Actuator switch falls off | Cannot remove/refill reservoir | Retention screw loosening | Use integral locking feature instead of screw | Replace screw | 4 | 1 | 1 | 4 |

| Battery Cover | Hinge breaks | Cannot be closed, broken circuit, inoperation (no motor) | Physical abuse | More robust/less protrusive hinge lugs | None | 6 | 1 | 1 | 6 |

| Threaded insert breaks out | Cannot be closed, broken circuit, inoperation (no motor) | Screw overtightening, physical abuse | Thicker plastic around insert | None | 6 | 1 | 2 | 12 | |

| Shell | Cracking | Expose gear train to debris, create sharp edges | Physical abuse | Thicker plastic, though design seems sufficiently robust as-is | None | 7 | 3 | 1 | 21 |

| Halves separate | Lose component alignment, expose gear train to debris | Screws loosening, user tampering | None, plenty of redundant screws already | Retighten/replace screws | 3 | 2 | 2 | 12 |

Design for Environment (DFE)

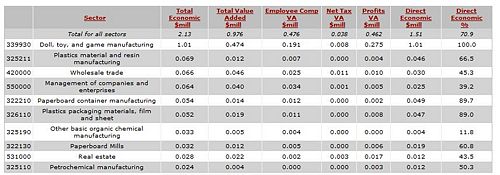

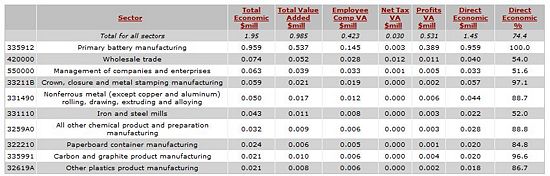

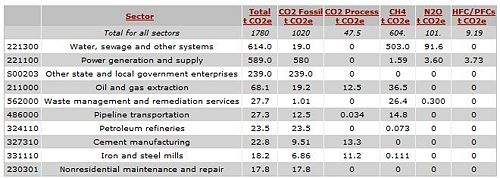

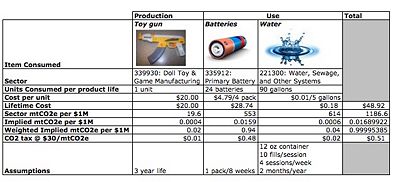

The Saturator AK-47 Water Gun is composed of cheap plastic and metal components, none of which consist of environmentally conscious designs. The use of the water gun validates this claim even further with the amount of batteries and water used during the life of this product. To analyze the environmental effects of the water gun in further detail, an Economic Input Output Life Cycle Analysis (EIO-LCA) method was used to estimate the economic, energy, and greenhouse gas effects of the product. Three major sectors of the United States' industry output contributes to the production of Saturator AK-47 Water Gun: Toy & Game Manufacturing, Primary Battery Manufacturing, and Water Manufacturing, in which data was taken using the 2002 US benchmark to determine the negative effects of the water gun's production and use on the environment (end of life ignored).

Economic Analysis

Taking a closer look at the components that affect the water gun's cost, the actual water gun toy and the batteries used are the greatest contributors to the cost of production and use. This is due to the fact that the price of rapid manufacturing machines such as direct injection machines have a very steep initial cost. As shown in the images below, the doll, toy, and game manufacturing along with primary battery manufacturing are both the largest sectors for their category. Thus, they serve as good estimates for the overall cost of manufacturing the Saturator AK-47 water gun. On the other hand, water sewage systems do not take up a large amount of economic activity, implying that the water analysis is a very rough estimate for it's total cost.

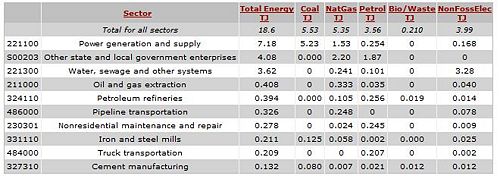

Energy Analysis

The amount of energy consumed by each sector involved in manufacturing and using the Saturator AK-47 is shown below. Looking at the product components that use the greatest amounts of energy, it is clear that water manufacturing uses the greatest amount of energy. This is because water treatment and sewage systems consume large amounts of energy.

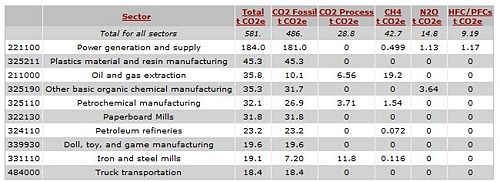

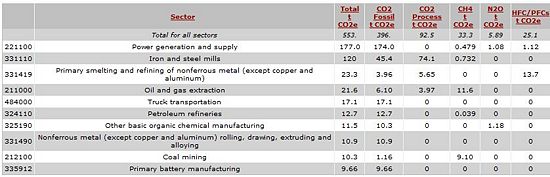

Greenhouse Gas Analysis

When analyzing the amount of greenhouse gases that the manufacturing and use of this product produces, it was found that the batteries of the Saturator water gun are the greatest contributor to pollutants. Aside from this aspect, the design of this water gun is environmentally conscious, and is also low cost for manufacture.

Results

The overall environmental impact of the Saturator AK-47 Water Gun is rather small when compared to that of a coffeemaker or other consumer products. When looking at the specific components of the Saturator, it is evident that batteries are the greatest contributor to greenhouse gases. If Congress were to pass a tax on CO2, there would not be a large effect on the cost of manufacturing water gun. However, there would be a relatively larger on use of the product as it would raise the cost of batteries by approximately $.48. This may deter some parents from buying their child a battery operated water gun over a manual pump operated toy. However, in comparison to how other consumer products could potentially be effected by a CO2 tax the production and use of the Saturator AK-47 Water Gun is not largely effected.

Through the EIO-LCA analysis it is evident that there are a number of changes that can be made to improve environmental effects of the Saturator AK-47. Although its environmental impact is already minimal when looking at the broader scale there is always going to be room for improvement. To lessen the manufacturing carbon footprint, a material other than cheap thermoplastic could be utilized (perhaps even a material that is biodegradable), though this course of action would increase the production costs of the product. On the other hand, the negative environmental effects can be lessened by minimizing or even eliminating the use of batteries.

This could be done by perhaps increasing the battery capacity, using rechargeable batteries, or charging the water gun through other another method (eg. solar panels). The amount of water used per game can also be lowered by minimizing the amount of water leaking from the gun. These options would definitely minimize the Saturator's environmental impact, but could possibly raise the manufacturing costs too much for these changes to be beneficial for the manufacturer.

Although the end of life analysis for this product has been omitted, the Saturator AK-47 has a harsher effect on the environment than what our calculations show because it is a product that will likely end up in landfill.

Team Roles

Santia Valerio- Team Lead - Executive Summary, Stakeholders and User Studies

Jonathan Daneman- FMEA, Mechanical Functioning Lead - FMEA Analysis and Product Function

Min Jung Kim- DFMA Lead - Bill of Materials, DFMA and Assembly

Mana Heshmati- DFE Lead - DFE Analysis and Usage

References

[1] Dieter, George Ellwood and Linda C. Schmidt. Engineering Design. Boston, McGraw-Hill Higher Education, 2009.

[2] Carnegie Mellon University, Green Design Institute. Economic Input-Output Life Cycle Assessment, 2008. US 2002 Industry Benchmark. http://www.eiolca.net/.