Snowboard binding

From DDL Wiki

| Line 2: | Line 2: | ||

| - | + | ||

| + | ---- | ||

| + | |||

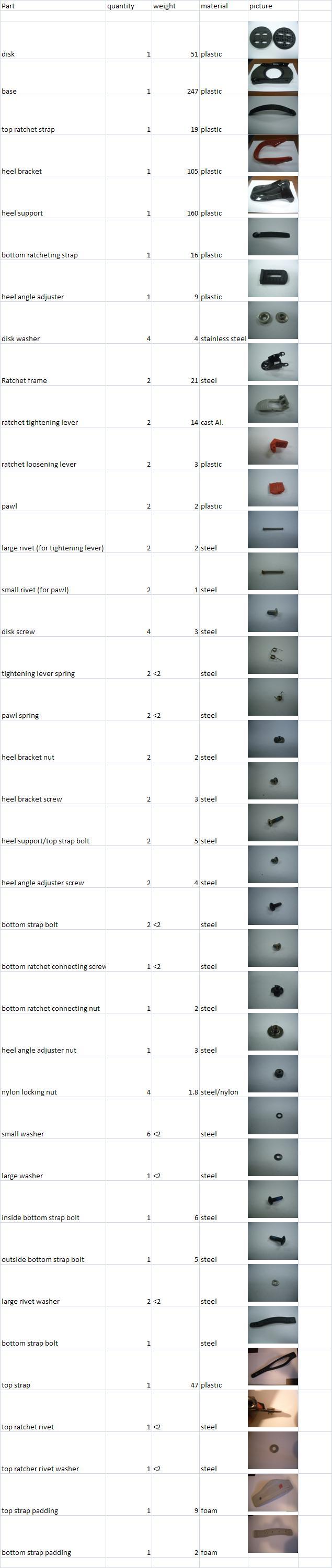

The following is a parts list of all the components that make up '''ONE''' snowboard binding (as in the left or right, but not both). It includes the weight of each component, the material which it is made of, and a picture of the piece. | The following is a parts list of all the components that make up '''ONE''' snowboard binding (as in the left or right, but not both). It includes the weight of each component, the material which it is made of, and a picture of the piece. | ||

| - | + | ||

| + | |||

[[Image:Partslist.jpg]] | [[Image:Partslist.jpg]] | ||

| + | |||

| + | Failure Modes and Effects Analysis | ||

| + | Failure modes and effects analysis (FMEA) is an effective tool in identifying a product’s strengths and weaknesses. The process begins by listing all components/parts of a product. Each component is then analyzed to determine different possible failure modes and effects of each failure mode. The failures are rated according to the legend below. The failures and effects of failures are assessed on a scale from 1 to 10, 1 being lowest and 10 highest. Finally, a recommended action may be proposed if necessary and each component is reevaluated (*). | ||

| + | The table below lists the separate components of a snowboard binding and assesses different modes in which these components may fail. | ||

| + | Legend : | ||

| + | (S) – Severity of the Failure | ||

| + | (O) – rate of occurrence | ||

| + | (D) – Detectability of the problem | ||

| + | RPN – Risk Priority Number; = S*O*D | ||

Revision as of 13:51, 20 September 2009

The following is a parts list of all the components that make up ONE snowboard binding (as in the left or right, but not both). It includes the weight of each component, the material which it is made of, and a picture of the piece.

Failure Modes and Effects Analysis Failure modes and effects analysis (FMEA) is an effective tool in identifying a product’s strengths and weaknesses. The process begins by listing all components/parts of a product. Each component is then analyzed to determine different possible failure modes and effects of each failure mode. The failures are rated according to the legend below. The failures and effects of failures are assessed on a scale from 1 to 10, 1 being lowest and 10 highest. Finally, a recommended action may be proposed if necessary and each component is reevaluated (*). The table below lists the separate components of a snowboard binding and assesses different modes in which these components may fail. Legend : (S) – Severity of the Failure (O) – rate of occurrence (D) – Detectability of the problem RPN – Risk Priority Number; = S*O*D