Snowboard

From DDL Wiki

(→Design for Environment) |

(→Design for Environment) |

||

| Line 489: | Line 489: | ||

== Design for Environment == | == Design for Environment == | ||

| - | |||

| - | |||

| - | |||

A snowboard has very low greenhouse gas emissions in use. The only emissions associated with use are the additional emissions from transport, which we consider negligable if transported inside a vehicle, but could be significant if transported externally, as for example on the roof of a car which would add drag. | A snowboard has very low greenhouse gas emissions in use. The only emissions associated with use are the additional emissions from transport, which we consider negligable if transported inside a vehicle, but could be significant if transported externally, as for example on the roof of a car which would add drag. | ||

Revision as of 19:57, 11 February 2012

Contents |

Executive Summary

Stakeholders

We have identified four major stakeholders in the life cycle of the competitor's product: the user, the retailer, the manufacturer and the shipping company. Below is a list of the needs of each stakeholder concerning the product.

Users

The user is the main person to use the product, therefore his needs are the ones that should be first taken into consideration when redesigning the competitor's product.

- Low price

- Light with sufficient rigidity and flexibility

- Durable

- Board should have sharp edges but remain safe to carry

- Adjustability and strength of bindings

- Ergonomics of bindings: they should be easy to strap on and release

- Appearance, branding

Retailers

The needs of the retailer are centered around making profit by selling the product, and facilitating the after-sales service.

- Profitability

- Appearance, branding, appeal

- Easy to store: small weight and dimensions

- Serviceability: standardization of parts

Manufacturers

The needs of the manufacturers are aimed at easy and cheap manufacturability.

- Simple geometries

- Limited number of parts

- Cheap materials that are easy to work with

- Cheap manufacturing processes

- No toxic materials

- Easy to store: small weight and dimensions

Shipping Companies

The shipping companies want an easy to carry product.

- Package should be light and compact

- Durable: resistance to vibrations and shock

- Replacement parts must be easily shippable

Use Study

The main steps in using the product are listed below.

- Travel to mountain and ski resort

- Purchase ticket

- Put on boots, hat, gloves

- Strap front foot into binding

- Take ski lift and get to the top of mountain

- Strap rear foot into binding

- Go down the slope: set edge, shift center of gravity and twist board to turn, traversing the fall line

- Unstrap rear foot and return to step 5

Mechanical Function

Product Parts

Exploded Assembly

Bill of Materials

Table: Components of Snowboard

Design for Manufacture and Assembly

Failure Modes and Effects Analysis

Design for Environment

A snowboard has very low greenhouse gas emissions in use. The only emissions associated with use are the additional emissions from transport, which we consider negligable if transported inside a vehicle, but could be significant if transported externally, as for example on the roof of a car which would add drag.

The emissions caused by the added drag can be estimated by considering a increase in fuel consumption of 5% when using a ski rack [ 1 ] . When estimating an average driving distance to snowboard as 200 miles, a car with 20 miles/gallon, 5 trips/year, a 10 year life span and an average of 3 snowboards in the rack, the amount of gas needed to compensate for the ski rack can be estimated to 8.3 gallons. Considering 8.9 kg CO2 per gallon of gas [ 2 ] the total CO2 emissions from the use of a snowboard is approximately 75 kg. For such a rough estimate it is natural to round it to the order of magnitude of 0.1t CO2.

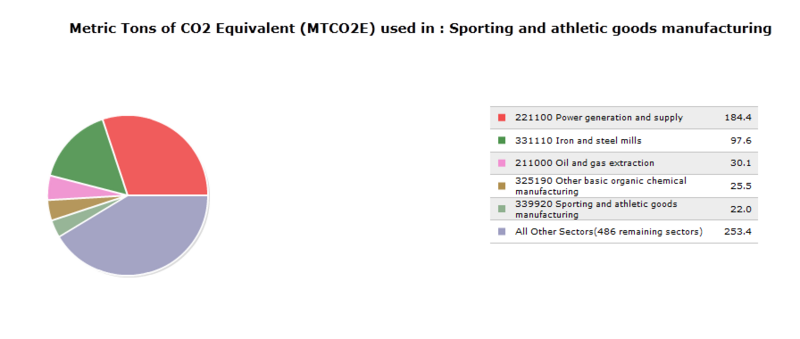

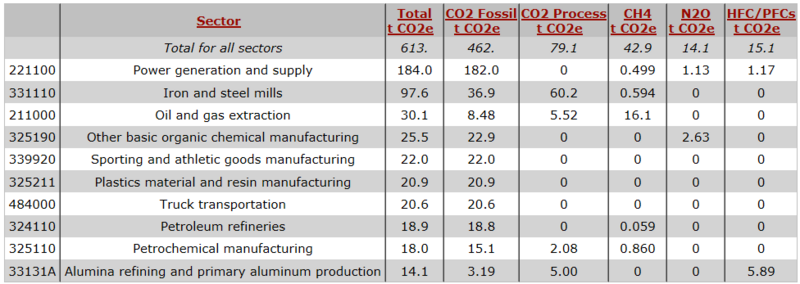

To estimate the amount of CO2 emissions from manufacturing we used the EIO-LCA method [ 3 ] to create the table. This method gives a total of manufacturing emissions as 0.25t CO2 when considering an average price of 400$ for a snowboard.

Table [1]: CO2 emissions for 1 million $ spent in the sporting and athletic goods manufacturing sector

However the method is very unprecise in our case as snowboards only represents a small fraction of the sporting and athletic goods manufacturing sector, so the value found represents the average emissions from all sports equipment which could vary enormously from one product to another.

DFE Conclusions

The total estimated CO2 emissions from the board are thus 0.35t. The conclusions are that if a tax of 40$ per ton CO2 is implemented, the snowboard would cost 14$ more. A consumer would probably not be affected by this increase in price, however if the cost is paid by the manufacturers it would be significant as they would lose 14$ times number of boards sold. Transporting the snowboard accounts for around 30% of this CO2 cost and reducing this is what our group identifies as the main area in which the snowboards carbon footprint can be improved.

Team Roles

Saviz Mowlavi - Team Leader

Evan Walden - FMEA Lead

Philip Brown - DFMA Lead

Erik Ringvold - DFE Lead

Christopher Tomaszewski

References

[1] http://editorial.autos.msn.com/article.aspx?cp-documentid=435406 [2] http://www.eia.gov/oiaf/1605/coefficients.html [3] http://www.eiolca.net/