From DDL Wiki

Executive Summary

Stakeholders

Consumer

Retailer

Manufacturer

Shipping

Use Study

Mechanical Function

Product Parts

Exploded Assembly

Bill of Materials

Table: Components of Snowboard

| Part #

| Part Name

| Quantity

| Material

| Function

| Manufacturing process

| Weight [g]

| Image

|

| 1

| Screw (1)

| 8

| Steel

| Fixes bindings to board

|

| 5

|

|

| 2

| Washer (1)

| 4

| Steel

| Protects piece from screw

|

| 0.75

|

|

| 3

| Nuts (1)

| 4

| Steel

| Attach strap to binding

|

| 8

|

|

| 5

| Buckle Screw

| 1

| Steel

| Attaches buckle to strap

|

| <1

|

|

| 6

| Strap (1)

| 1

| Plastic

| Fixes upper part of boot to binding

| Injection

| 16

|

|

| 7

| Plastic Piece (1)

| 1

| Plastic

|

|

| <1

|

|

| 8

| Screw (2)

| 1

| Steel

|

|

| 9

|

|

| 9

| Screw (3)

| 1

| Steel

|

|

| 4

|

|

| 11

| Metal Ring

| 4

| Steel

| Protect plate (n°18) from screws

|

| 1.5

|

|

| 12

| Screw (4)

| 1

| Steel

|

|

| <1

|

|

| 13

| Large Anchor Nut

| 1

| Steel

| Attaches foam pad (n°46) to straps (n°-)

|

| <1

|

|

| 14

| Small Anchor Nut

| 1

| Steel

| Fixes strap (n°22)

|

| <1

|

|

| 15

| Angle Limiter

| 1

| Plastic

| Limits angle of pad (n°24)

| Injection

| 10

|

|

| 16

| Plastic Square

| 1

| Plastic

| Attaches angle limiter (n°15) to pad (n°24)

| Injection

| 9

|

|

| 17

| Strap (2)

| 1

| Plastic

| Fixes lower part of boot to binding

| Injection

| 9

|

|

| 18

| Circular Plate

| 1

| Plastic

| Allows different angles between board and binding

| Injection

| 68

|

|

| 19

| Pad (1)

| 1

| Foam

| Softens connection between leg and binding

|

| 6

|

|

| 20

| Washer (2)

| 1

| Steel

|

|

| <1

|

|

| 21

| Strap (3)

| 1

| Plastic

| Attaches buckle and fixes lower part of boot

| Injection

| 10

|

|

| 22

| Strap (4)

| 1

| Leather

| Fixes lower part of boot

|

| 33

|

|

| 23

| Nut (2)

| 1

| Steel

|

|

| <1

|

|

| 24

| Pad (2)

| 1

| Plastic

| Holds rear of boot

| Injection

| 133

|

|

| 25

| Base

| 1

| Plastic

| Frame of binding

| Injection

| 276

|

|

| 26

| Damper

| 1

| Rubber

| Dampers vibrations and shocks from board to binding

|

| 79

|

|

| 27

| Metal Fixation (1)

| 1

| Steel

| Frame of buckle

|

| 12

|

|

| 28

| Lever (1)

| 1

| Plastic

| Opens or closes buckle

|

| 5

|

|

| 29

| Metal Fixation (2)

| 1

| Steel

| Frame of buckle

|

| 12

|

|

| 30

| Rivet (1)

| 1

| Steel

| Connects angle limiter (n°15) pieces

|

| <1

|

|

| 31

| Rivet (2)

| 6

| Steel

| Connects buckle pieces

|

| 1

|

|

| 32

| Washer (3)

| 1

| Steel

|

|

| <1

|

|

| 33

| Metal Fixation (3)

| 1

| Steel

| Frame of buckle

|

| 26

|

|

| 34

| Lever (2)

| 1

| Aluminium

| Opens or closes buckle

|

| 19

|

|

| 35

| Plastic Piece (2)

| 1

| Plastic

| Holds buckle pieces in place

| Injection

| 4

|

|

| 36

| Spring (1)

| 1

| Steel

| Returns lever to original position

|

| <1

|

|

| 37

| Rivet (3)

| 1

| Steel

| Connects buckle pieces

|

| <1

|

|

| 38

| Rivet (4)

| 1

| Steel

| Connects buckle pieces

|

| <1

|

|

| 39

| Plastic Piece (3)

| 1

| Plastic

| Holds buckle pieces in place

| Injection

| 5

|

|

| 40

| Metal Fixation (4)

| 1

| Steel

| Frame of buckle

|

| 22

|

|

| 41

| Lever (3)

| 1

| Plastic

| Opens or closes buckle

| Injection

| 4

|

|

| 42

| Plastic Piece (4)

| 1

| Plastic

| Holds buckle pieces in place

| Injection

| <1

|

|

| 43

| Spring (2)

| 1

| Steel

| Returns lever to original position

|

| <1

|

|

| 45

| Board

| 1

| Steel, Resin, Plastic

| Glides on snow and cuts ice with its edges, frame of bindings

|

| 3518

|

|

| 46

| Foam Pad

| 1

| Foam

| Softens connection between foot and strap

|

| 49

|

|

| 47

| Plastic Retainer

| 1

| Plastic

| Fixes upper part of boot

| Injection

| 65

|

|

| 48

| Bolt

| 1

| Steel

| Connects foam pad (n°46) to retainer (n°47)

|

| <1

|

|

Design for Manufacture and Assembly

Failure Modes and Effects Analysis

Design for Environment

A snowboard has very low greenhouse gas emissions in use. The only emissions associated with use are the additional emissions from transport, which we consider negligable if transported inside a vehicle, but could be significant if transported externally as for example on the roof of a car which would add drag.

The emissions caused by the added drag can be estimated by considering a increase in fuel consumption of 5% when using a ski rack [X]. When estimating an average driving distance to snowboard as 200 miles, a car with 20 miles/gallon, 5 trips/year, a 10 year life span and an average of 3 snowboards in the rack, the amount of gas needed to compensate for the ski rack can be estimated to 8.3 gallons. Considering 8.9 kg CO2 per gallon of gas [Y], the total CO2 emissions from the use of a snowboard is approximately 75 kg. Being such a rough estimate it seems natural to round it to the order of magnitude of 0.1 t CO2.

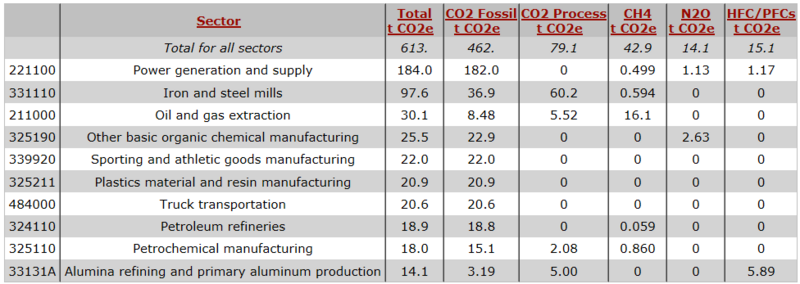

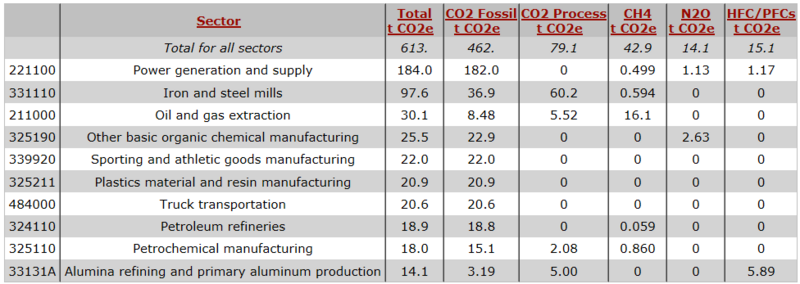

We assume that the main emmisions of greenhouse gas will be caused by the manufacture of the snowboard. To estimate the amount of this we used the EIO-LCA method. This gave a total of manufacturing emissions as 0.25t CO2 considering an average price of 400 dollars for a board.

However the method is very unprecise in our case as snowboards only represents a fraction of the sporting and athletic goods manufacturing sector, so it represents the average emmisions of all sports equipment which could vary enormously from one product to another.