Power scrubber

From DDL Wiki

Contents |

Exectuve Summary

Major Product Stakeholder Analysis

We identified four major categories of stakeholders for our product. They are manufacturers, shipping & transportation companies, retailers, and consumers.

Stakeholder Objectives

- Manufacturers

Low cost raw materials Simple manufacturing process required for materials chosen -- easy for mass production Energy efficient manufacturing process Recyclable materials Easy assembly Low cost packaging

- Shipping & transportation companies

Firmly packaged Light weight packaging Space efficient mass packaging

- Retailers

Appearance Cost Marketability (consumer needs) Durability

| Stakeholder Needs and Wants | ||

|---|---|---|

| Stakeholder | Needs | Wants |

| Consumer |

|

|

| Retailer |

| |

| Manufacturer |

|

|

| Shipping & Transportation |

|

|

Product User Study

Mechanical Function

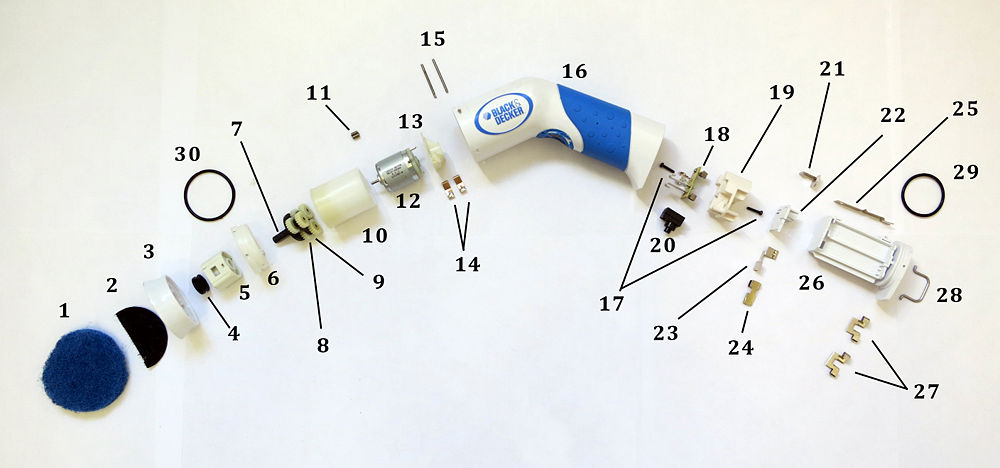

Parts List

| Part Number | Name | Quantity | Mass (g) | Subassembly | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|---|

| 1 | ||||||||

| 2 | ||||||||

| 3 | ||||||||

| 4 | ||||||||

| 5 | ||||||||

| 6 | ||||||||

| 7 | ||||||||

| 8 | ||||||||

| 9 | ||||||||

| 10 |

Design For Manufacturing and Assembly

DFM

The product use standarize components for many of the components such as the screws, motor, and velcro. All the conducting metal pieces have similar dimensions, which requires fewer tools and setups during the manufacturing process. Also, most parts are made of the same material, ABS, which are easy to work with as well. Since injection modings are used for the ABS parts, not many finishing opeartions are needed. The product take advantages of the rubber rings as a seal for water proofing as well as a locking mechanism for holding parts together. The rubber rings also helps the avoid tight tolerances that can result in higher cost. For the outer shell, special process, joining ABS and rubber together are used.

DFA

Failure Mode and Effect Analysis

| Item and Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|

| Battery Housing | Battery housing comes loose | No Power Source | 4 | Not closing properly | 4 | Scrubber would not turn on | 2 | 32 | A better clicking mechanism |

| Button: ON/OFF | Button sticks | Can't turn on or can't turn off | 4 | Alignment of button | 2 | Scrubber would not turn on | 1 | 8 | Make it a flip switch |

| Outter Shell | Cracking | No longer water proof | 4 | Dropping, crushing, overheating | 5 | Scrubber would not turn on | 2 | 40 | Coat entire body with rubber |

| Rubber gripping/waterproofing | Melts or wear and tear | No longer waterproof | 3 | Heat | 2 | Scrubber would not turn on | 3 | 18 | Better material choice |

| Motor-circuit board connection | Welding of copper loosens | Motor does not run | 4 | Fatigue, Overheating | 1 | Scrubber would not turn on | 3 | 18 | Better mesh of the motor with the circuit board |

Design For Environment

| Production | Use | Use | Use | Use | |

|---|---|---|---|---|---|

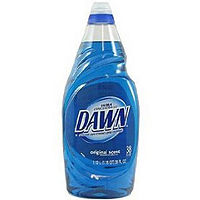

| Item purchased | Power Scrubber Manufacturing | Battery | Sponge | Soap | Water |

| a) Picture | |||||

| b) Economic Sector Name and # | Small Electric appliance #335210 | Primary battery manufacturing #335912 | Broom, brush, and mop manufacturing #339994 | Soap and cleaning compound manufacturing #325610 | Water, sewage and other systems #221300 |

| c) Reference Unit | 1 item | 4 batteries | 1 piece | 16 oz/bottle | 19.5 gallon/day |

The Team

Team Leader: Xin (Pam) Hu

DFMA Leader: Ken-Soh (Robert) Mai

FMEA Leader: Ben Antoine

DFE Leader: Kelle Patterson

User Study Leader: Shao-Chuan (Ted) Fang