Lamp stand mechanical arm

From DDL Wiki

(→'''Stakeholders''') |

(→'''Executive Summary''') |

||

| Line 7: | Line 7: | ||

Consumers buy a lamp to provide light in a specific area. Consumers buy this specific lamp because of its range of motion. The user is able to change the position by simply moving the lamp to the desired position and tightening some screws. Manufacturers produce this product because a lamp is a popular piece of office equipment. This lamp was purchased for ten dollars. Its low price is very desirable for consumers and manufacturers alike because the cheaper a product is without sacrificing its integrity, the greater the number of units sold. | Consumers buy a lamp to provide light in a specific area. Consumers buy this specific lamp because of its range of motion. The user is able to change the position by simply moving the lamp to the desired position and tightening some screws. Manufacturers produce this product because a lamp is a popular piece of office equipment. This lamp was purchased for ten dollars. Its low price is very desirable for consumers and manufacturers alike because the cheaper a product is without sacrificing its integrity, the greater the number of units sold. | ||

| - | + | The five main | |

| + | |||

== '''Stakeholders''' == | == '''Stakeholders''' == | ||

Revision as of 22:12, 24 September 2008

Contents |

Executive Summary

The entire lamp has been broken down and studied, but the specific interest in this lamp is the construction and function of its mechanical arm. Before taking the lamp apart, possible uses and range of motion were discussed. When taking the lamp apart, each part was photographed, weighed, and inspected for possible manufacturing process.

Consumers buy a lamp to provide light in a specific area. Consumers buy this specific lamp because of its range of motion. The user is able to change the position by simply moving the lamp to the desired position and tightening some screws. Manufacturers produce this product because a lamp is a popular piece of office equipment. This lamp was purchased for ten dollars. Its low price is very desirable for consumers and manufacturers alike because the cheaper a product is without sacrificing its integrity, the greater the number of units sold.

The five main

Stakeholders

There are a total of five major stakeholders documented in the following section these are: raw material suppliers, design engineers, manufacturing, assembly/packaging and the consumer. Their needs have been identified, crucial communications between stakeholders have been explicitly highlighted, and a detailed description of the process of consumer using the product have been provided. It is hoped that this will give Initech an in-depth understanding of the marketplace and firm grasp on how the consumer and product interact.

There are three types of raw material suppliers used in the manufacture of the lamp; these are the aluminum sheet suppliers, the plastic pellet suppliers and the electrical equipment suppliers. The suppliers have minimal interest in the final product, but they are interested in the use of the final product. If the suppliers supply faulty materials, they are liable for suit by Initech as a result of any harm caused by their materials.

The aluminum and plastic suppliers have two basic critical to quality issues with regard to our product. They must ensure that they provide accurate technical specifications for their aluminum. These specifications are important to Initech in the manufacture of the aluminum parts because Initech wants to match the stamping equipments hardness rating specifically to a certain aluminum alloy. The plastic suppliers have a similar concern; they want to provide the correct specification for the plastic they use because Initech’s machines will be calibrated for a certain type of plastic. In both cases if the technical specifications are not correct, Initech might be forced to halt production or search for a new supplier.

The electrical suppliers have similar concerns to the previously mentioned suppliers. It is assumed they have an internal quality measurement system. Since this is most likely the case, the electrical components suppliers will ensure that the secondary suppliers are meeting the electrical technical specifications. They will selectively run tests to confirm their electrical units are meeting specifications. These specifications are crucial to Initech since they will be relayed to the consumer; a misunderstanding in relaying these specifications could lead to a fire in the location of use.

Design engineers are concerned about the entire production process from inception to end of life. The most critical need of the design engineer is understanding the end user. It is only in this way she can make correct decisions on the design of the product. The engineer must also be familiar with the manufacturing processes that could be utilized. This way the most economical choice may be made in manufacturing the part, while maintaining critical design parameters. A design engineer must also be well versed the current products on the market. This way the engineer can observe her current market and how other products function and create innovations to hopefully facilitate growth for Initech. Then she must also understand the suppliers products and how she can best integrate the suppliers products and Initech’s ideas to make the product go to full production at a minimal cost. Also in designing the part an acceptable tolerance must defined by the engineer in order for the part to be produced at a reasonable cost. They will also want to create a process which will minimize waste as much as possible from the original raw material purchased. The design engineer will also be concerned with creating a product that is as light weight as possible and that can be disassembled into as feasibly small a volume as possible.

In the production phase of the products life there are two major stakeholders; these are the personnel involved with processing the raw materials to parts which meet the design engineers specifications (henceforth manufacturing) and the people involved with assembling and packaging the product to be shipped to its final location.

Even for a product that seems simple, manufacturing has a significant amount of concerns to be addressed as one of the key stakeholders. One of manufacturing’s key concerns is meeting the specifications that are required by the design engineer. This is not simple when thousands of parts are being manufactured. Manufacturing’s function is to decrease the variation when producing the part. This means that they must be aware of the tolerances being chosen by the design engineer and giving feedback on the feasibility of those tolerances. Another significant concern of manufacturing is the safety of the shop floor. Manufacturing will seek safety guidelines that ensure the part is being made in due time, while preserving safety. Since manufacturing will have the most experience with manufacturing hardware, they should be given the task of searching for companies to provide the machinery needed to machine the raw material. They are concerned with finding the correct die, presses, and stamps such that there is not excess cost with purchasing these parts due to overcompensation on the requirements for the parts. Since the failure of one of these parts would cause a stop in the production line manufacturing is also concerned with having clear instructions and labels on how to use the machinery. They are also concerned with minimizing the number steps in the manufacturing process to streamline their own production lines. With regards to manufacturing the plastic parts, they are concerned with being able to create a mold which will successfully solidify the plastic evenly and allow for easy removal of the plastic part created. They are also concerned with easy transitions between phases. The easier the transition between phases in the manufacturing process the more parts they can manufacture.

The next phase of the products life carries a new set of stakeholders for the product: assembly and packaging. Assembly’s main concern is to have an assembly procedure which is efficient, clearly communicated and uses as little tooling as possible. A key priority is to always keep the assembly process going so measures must be taken to account if their tooling breaks. Since their tools are relatively inexpensive, assembly will want to make sure that they have a supply of back-up tooling. They also want to make sure that the tooling they choose for the specified process is the optimal tool for that step. As a final check assembly might want to create a process that selectively tests products to make sure they meet the requirements of the design engineer before send the product to packaging. Packaging is concerned with minimizing shipping costs of the part. That said they would like to be able to have an assembly which when disassembled takes up as little volume as possible. This would allow Initech to use as little packaging material as possible. They are also concerned with obtaining as light a product as possible to minimize shipping costs. Packaging might also be interested in including vital information on the product on the box, making it easy for consumers to decide if the product meets their needs. In the box packaging will want to make sure the consumer's information sheet has all vital information about the safe operation of the lamp.

The consumer needs many things from the lamp. The first time the consumer comes in contact with the product it will be packaged. So the packaging must include all vital information about the lamp, such as maximum wattage or voltage. The consumer wants a lamp which is very easily assembled preferably with no instructions even needed and the no tooling required either. The consumer can use the lighting for many purposes and as such the light must be flexible such that it can be easily moved from one position to the other with the minimal force required. With a low-cost lighting option like the one Initech has it may not be desirable to invest money is ergonomics, but when the consumer interacts with the product he wants to have a location where he can hold onto the lamp and move it easily. Some consumers also like to use their lamps for mood lighting. Having a lamp whose bulb can face up toward the ceiling or wall will only increase the desirability of the lamp. The consumer also wants to be able to use as high a wattage bulb as possible in the lamp to provide maximum light when needed. He also wants an easy on/off feature to the lamp. The cord of the lamp must also be long enough to allow the consumer to place the lamp a good distance from the power source, but not so long as to get tangled up.

Use of Lamp

The steps to using our lamp is as follows:

1. Unpack the lamp.

2. Connect the lamp shade to the lamp (trouble finding where the connection points were). Note the instructions for this step would have helped.

3. Attach the base of the lamp to the end of desk or the end of a shelf.

4. Insert the male portion of the lamp into the female base of the lamp such that the male portion is always pointing downward.

5. Connect the lamp to a power source.

6. Turn on the lamp.

7. Extend the lamp such that it is over the workspace. This can be tedious because some unscrew the joints before they move the lamp. Others keep the screws tight enough so that the lamp can’t fall while allowing for motion. An alternative use at this point is creating mood lighting. This is when the lamp is pointed toward a surface so that reflected light fills the room not direct light.

System Function

The system is a mechanical arm that uses frictional joints to support a lamp.

The Base

The lower jaw, the threaded L bar, the thumb screw, and the upper jaw make up the base. The base unit attaches to the edge of a desk or table with the lower jaw positioned below it and the upper jaw on top. The threaded part of the L bar goes through the lower clamp then the wing nut while the shorter, unthreaded part goes through the upper clamp. The screw is used to tighten down the clamps and secure the clamp assembly to the table, fixing it from all translations and rotations. There is a hole at the top of it for a peg at the base of the arm unit.

Arm Unit

The arm has two parallel sets of equal bars that rotate at either end where it connects to plates that hold them in position relative to one another. The bottom holder has a peg on the bottom that inserts into the top of the top clamp in the base. Two of the bars attach to the bottom holder and run parallel up to the next set of joining plates. From these plates, two more bars run out of equal length up to another set of plates. These plates hold a fixture that rotates in the plane of the arm and holds the base peg of the plan unit. With this configuration of members, the top of the arm can move within a single plane that contains all the plates and members, allowing it to position along the two axes in the plane. There are screws at each joint that can be tightened to increase the friction in the joint to hold the arm in its current position.

Lamp Housing Unit

The lamp housing attaches to the arm with a peg that can rotate about its axis. This peg is screwed to the metal cup shaped housing that holds the fixture that the light screws into. There are holes cut in this part to allow heat dissipation from the lamp. A bowl shaped metal part is inserted and twisted into the opening of the cup to attach it. It serves to focus the light emitted from the bulb so that it may be directed and prevent it from blinding the user.

The Electrical Unit

The electrical unit has its most complex components within the Lamp Housing Unit. There is a threaded metal part that is made to allow for the insertion and securing of a light bulb. This part is riveted to a ceramic isolative part and further through to the switching assembly. The switch, when rotated, turns a small pin normal to its axis, causing it to contact two metal fingers, completing the circuit to turn on the lamp. To this switching assembly runs the power cable from outside the cup of the lamp housing to the switching assembly to provide power to the system. This cable runs down the upper members of the arm unit to the base of the arm unit where there are an additional six feet of cable with a typical 2 prong AC plug.

Mechanical Analysis

For the lamp fixture, one of the mechanisms essential to its operation is its friction joints. In the design process, there is a balance between how robust the joints are and the weight they can support. A more robust joint can of course hold a larger lamp on the end, but a joint that is too weak will not hold the lamp in place. It is safe to assume that creating a stronger joint will imply a greater cost for the joint. What is desired from this study is to find the strength of the current mechanisms and in looking ahead, make educated decisions in the design of our new product that will likely start with some structure of an arm mechanism and have similar components.

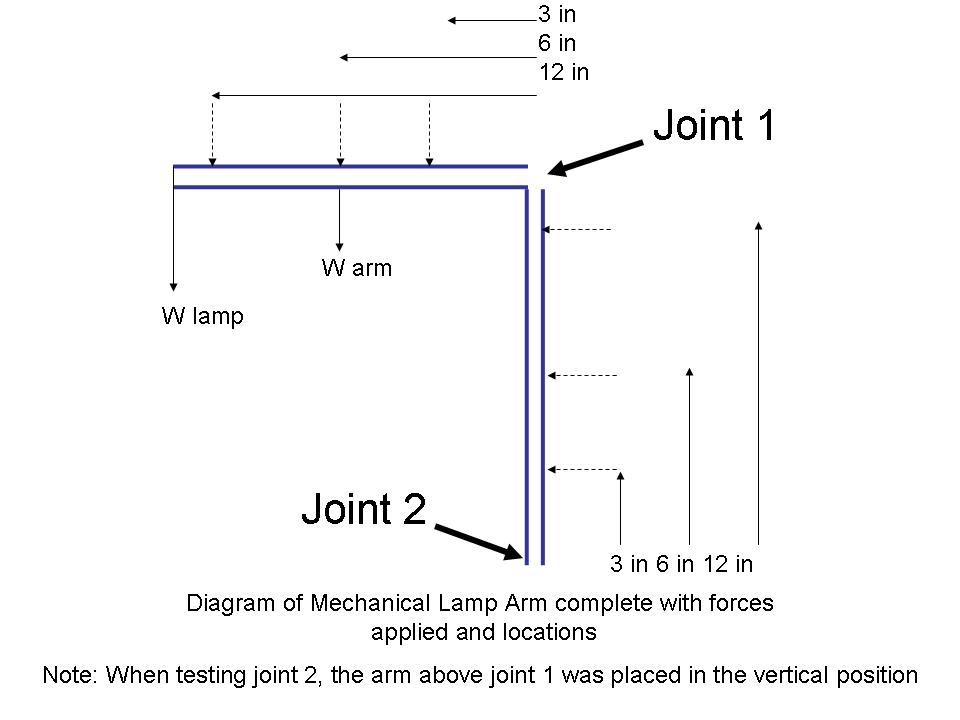

The tests in the mechanical arm were preformed on two different joints, one where a plastic wing nut was tightened down onto a single folded metal plate (Joint 2) and another where a plastic nut is tightened down onto a set of two independent metal plates (Joint 1). This study will show what the optimal material combination is and the maximum weight able to be supported by the arm.

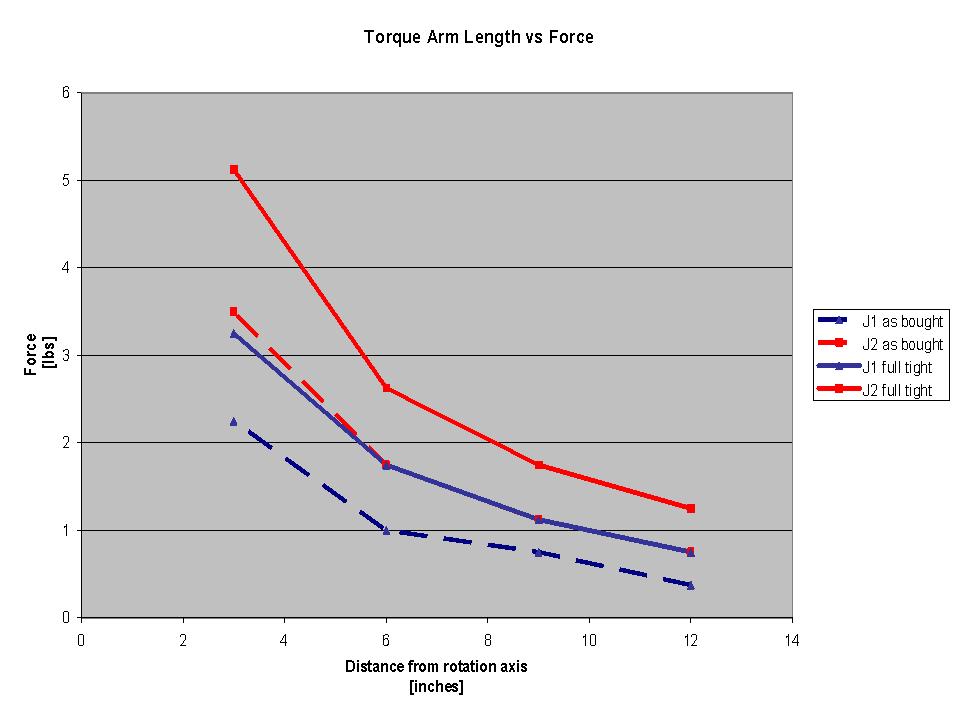

The initial study was preformed and the data collected as in the graph below. This graph shows the force required to cause motion in the mechanism against the length of the torque arm used. We know that T = dF where T is the torque applied, d is the length of the torque arm and F is the force applied at t he location. Given this function, assuming that the same torque needs to be applied at any location to disrupt the friction, then dF should stay constant and result in a linear graph. The first graph at the right confirms this phenomenon relatively well, indicating that the data is good for further analysis.

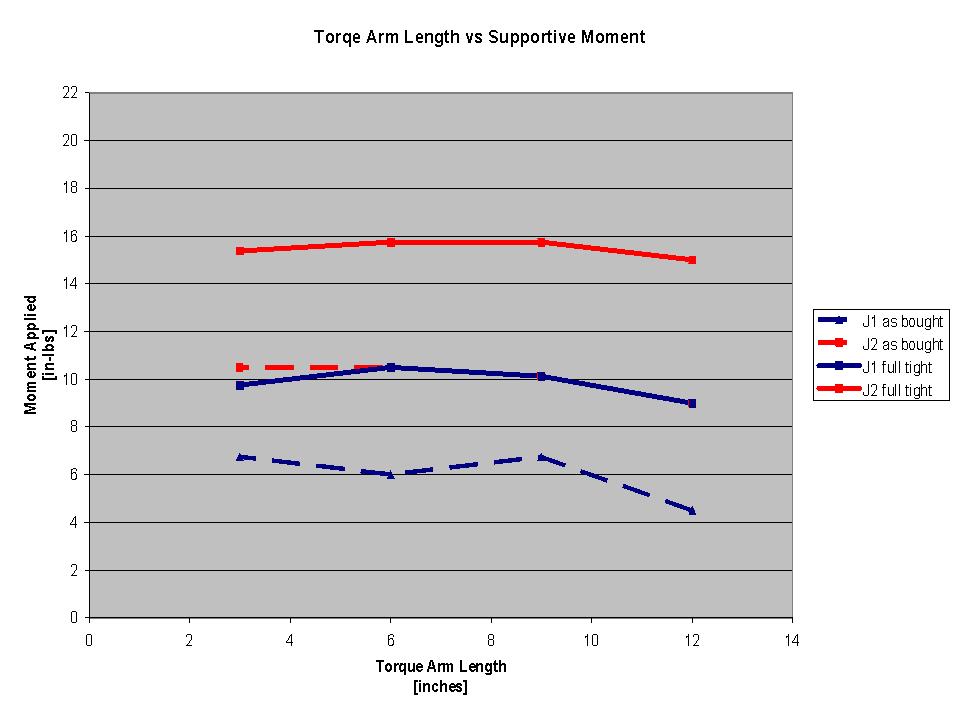

From this data, the torque applied was plotted against the length of the torque arm to check if the torque necessary was independent of the length of the torque arm (which is not always true in an unideal situation). The graph below confirms that the torque is relatively independent of the length of the torque arm, so we can continue finding what the moment is supplied by the screws in the joints.

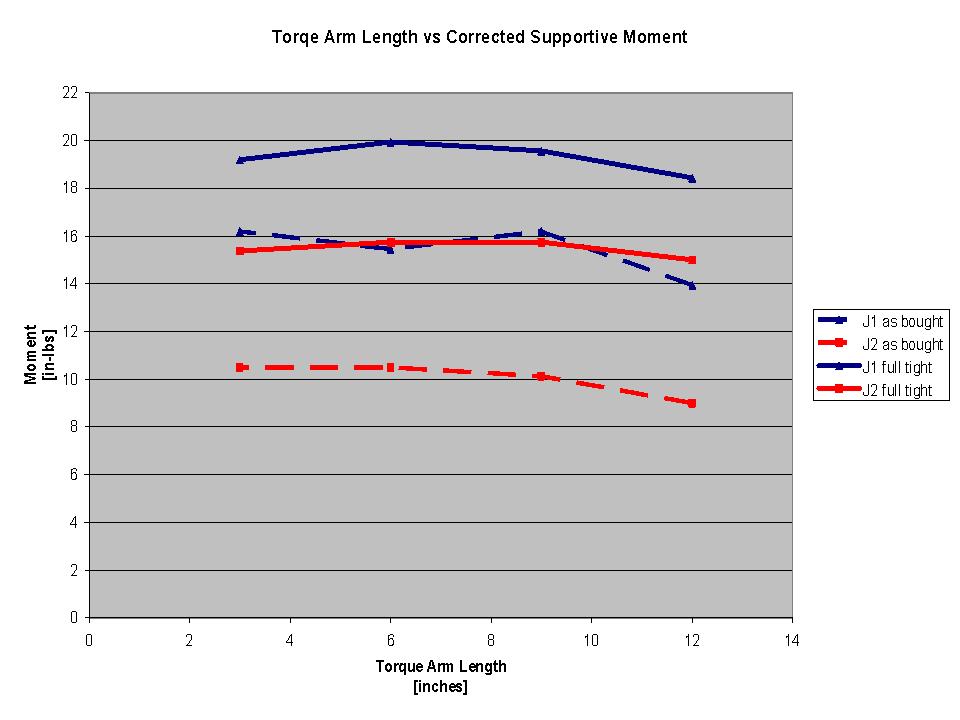

Due to the orientation, Joint 1 had additional loading on it beyond just the force applied using the spring scale which included the weight of the lamp fixture and the weight of the arm. In the case of joint 2, there was no additional loading. To account for this effect, the torques applied by the various components were computed from the weights collected during disassembly and the physical location from the fulcrum of the joint. The resulting torques were added to the torque applied to create the third chart of the actual maximum moments able to be supported by the joints.

The results are that the best material to maximize support is a plastic nut on a set of independent plates, and that in the case of the current model, a maximum torque of about 19 in-lbs, meaning that a mass of about 1.5 lbs could be supported at the end of the arm.

Components

| Part # | Part Name | Qty | Mass (g) | Function | Manufacturing Process | Material | Image | |

|---|---|---|---|---|---|---|---|---|

| 01 | Electric Cord | 1 | 114 | to transmit electricity from outlet to lightbulb | extrusion, cutting | aluminum, plastic, electric wires | ||

| 02 | Non-Cord Containing Rod | 1 | 48.19 | to increase distance from base to lightbulb | extrusion, machining | aluminum | ||

| 03 | Cord Containing Rod | 1 | 45.36 | to increase distance from base to lightbulb and contain electric cord | extrusion, stamping, machining | aluminum | ||

| 04 | Lamp Hood | 1 | 158.76 | to project and focus light from lightbulb | stamping | aluminum | ||

| 05 | Base | 1 | 17.01 | to mount lamp on a flat surface | injection molding | plastic |

| |

| 06 | Base Clamp | 1 | 8.5 | to hold base onto a flat surface | injection molding | plastic | ||

| 07 | Elbow Screw | 1 | 39.69 | to adjust clamp on base | pressing, tapping | aluminum | ||

| 08 | Cord Containing Rod End Cap | 4 | 0.9355 | to cover end of rod and to guide electric cord | injection molding | plastic | ||

| 09 | Non-Cord Containing Rod End Cap | 4 | 0.4706 | to cover end of rod | injection molding | plastic | ||

| 10 | Joint 1 | 1 | 22.68 | to attach lamp to base and adjust position | stamping | aluminum | ||

| 11 | Joint 2 | 2 | 14.18 | to attach bottom rods to top rods and adjust position | stamping | aluminum | ||

| 12 | Joint 3 | 2 | 5.67 | to attach lamp arm to lamp head and adjust position | stamping | aluminum | ||

| 13 | Friction Knob | 3 | 2.835 | to tighten joints and hold joints in place | injection molding | plastic | ||

| 14 | Friction Knob End Cap | 3 | 0.4706 | to cover ends of screws for friction knobs | injection molding | plastic | ||

| 15 | Small Nut | 8 | 1.418 | to hold screws in place | pressing, tapping | aluminum | ||

| 16 | Small Screw for Joints 2 & 3 | 5 | 2.835 | to hold joints together | pressing, tapping | aluminum | ||

| 17 | Joint 1 Knob Screw | 1 | 2.835 | to hold friction knob in place | pressing, tapping | aluminum | ||

| 18 | Joints 2 & 3 Knob Screw | 2 | 2.835 | to hold friction knob in place | pressing, tapping | aluminum | ||

| 19 | Light Bulb Socket Cover | 1 | 53.00 | to guard electronics and hold light switch | stamping | aluminum | ||

| 20 | Light Bulb Socket | 1 | 42.00 | to connect lightbulb to lamp and power | stamping, pressing, tapping, saudering | aluminum, copper, ceramics, electrical wires & components | ||

| 21 | Lamp Head Connector | 1 | 5.670 | to connect lamp head to joint 3 | injection molding | plastic | ||

| 22 | Lamp Head Connector Screw Holder | 1 | 1.418 | to contain screw that connects to Joint 3 friction knob | injection molding | plastic | ||

| 23 | Light Switch | 1 | 2.835 | to turn light on and off | injection molding | plastic | ||

| 24 | Cord Clip | 1 | 1.418 | to connect electric cord to light bulb cover | casting, molding | plastic | ||

| 25 | Cord Clip Ring | 1 | <0.01 | to make area around cord clip look nice | injection molding | plastic | ||

| 26 | Light Switch Ring | 1 | 1.418 | to connect light switch to light bulb cover | extrusion, cutting, tapping | aluminum | ||

| 27 | Light Switch Connector | 1 | 7.088 | to connect light switch to light bulb socket | extrusion, stamping | aluminum | ||

| 28 | Light Switch Connector Screw | 2 | 0.7088 | to hold light switch connector to lightbulb socket | pressing, tapping | aluminum | ||

| 29 | Lamp Head Connector Gasket | 1 | 1.418 | to go between lamp head and lamp head connector | cutting, stamping | aluminum | ||

| 30 | Lamp Head Connector Screw | 2 | 0.7088 | to hold lamp head connector to lamp head | pressing, tapping | aluminum | ||

| 31 | Light Switch Spring | 1 | <0.01 | to hold light switch in on/off positions | molding, cutting | brass | ||

| 32 | Light Switch Spring Pin | 1 | <0.01 | to resist light switch spring | pressing, tapping | brass | ||

| 33 | Base Clamp Knob | 1 | 1.418 | to adjust distance between base and base clamp | injection molding, tapping | aluminum, plastic | ||

| 34 | Base Clamp Knob Nut | 1 | 2.835 | to thread base clamp knob onto elbow screw | pressing, tapping | aluminum |

Design For X

There are many different considerations when working on design. This section describes the relevant considerations, and how we have seen them addressed in the creation of this lamp. This lamp is well designed when looked at a manufacturing and assembly perspective. There are few areas for improvement here, and those that exist are less important then many of the other issues. Therefore, it is our recommendation that improvements should be focused on other areas. In particular, disassembly and the environmental impact should be reevaluated.

Design For Manufacturing (DFM)

DFM is a process that optimizes the manufacturing of a product. The main considerations of this process are reducing cost such that it is cheaper to manufacture and simplifying the design such that it is easier to manufacture.

This lamp was well designed for manufacturing. It is a simple design, and uses cheap, easy to manufacture parts. Our only recommendation here is that one standard type of screw should be used instead of the current three.

Ways that DFM has been used on this lamp:

- The design is very simple, with few parts. A handful of screws hold the whole lamp together.

- The four rods in the lamp are created the same way, through extrusion, allowing the same machine to construct all of them. The one small difference between the cord containing rods and non-cord containing rods is in the machining.

- Screws are standard sizes which are easy to buy from manufactures.

- The cord runs through an already hollow rod, allowing the rod to fulfill multiple functions.

- The lamp hood is removable allowing for smaller packaging.

- Cheep metals and plastics were used in fabrication

Design for Assembly (DSA)

In DSA, the goal is to optimize the assembly process. Care is taken to make parts easy to attach, and to make the assembly sequencing clear.

The DSA process was well thought through for this lamp. The assembly is unambiguous and fasteners have been limited. Although there is very little to improve on with DSA, one small suggestion for improvement is to redesign the quadrilateral joints, as it is easy to confuse them or insert them in the wrong direction.

Ways that DSA has been used on this lamp:

- Unambiguous, assembly orientation.

- Part count has been minimized, a handful of screws hold the whole lamp together.

- The electrical cord and plug is a subassembly, able to be inserted quickly.

- The number of fasteners has been minimized. The lamp hood twits into place, the lamp sets into the base, and the cord is held in place by the end caps for the rods.

- Handling is minimized as the small number of parts with few places to fasten them makes the assembly process flow.

Design for Disassembly (DFD)

In DSA, the goal is to optimize the disassembly process. Care is taken to make parts easy to disassemble, and to make it easy to remove expensive or hazardous parts first such that they and be dealt with and the rest thrown away as need be.

The lamp designers did not take make DFD a priority when it was first designed. We have a few suggestions in how the to make this product easier to disassemble. Keep in mind, however, that there is very little value in the disassembled parts, so there is little incentive to disassemble.

Suggestions

- The cord threaded through the rods makes disassembly hard, as pieces stay attached unless the cord is cut.

- Another difficulty is encountered with the tight fitting end caps on the rods.

Design for Environment (DFE)

DFE is a process by which the environmental impact is considered, both from the creation of the product and thinking of what fate of the product will most likely be at the end of it’s life. Environmental impact is sought to be lessened, both by making the product easy to disassemble and by using materials that are produced in an environmentally safe way and which can be recycled.

There is much one can do with this lamp when using DFE. Many of the problems we observed stem from the lamp being hard to disassemble.

- The difficulty in disassembling makes it difficult to recycle parts, as the most economical end of life action is throwing the lamp away.

- The difficulty in disassembling makes it difficult to repair as well, causing the less-sustainable practice buying a new lamp instead of repairing the old one.

- In particular, the light bulb socket must be thrown out since it is practically impossible to disassemble and reuse

- Although we have a limited knowledge of the materials used, it is assumed that it would be possible to buy parts that are more environmentally friendly.

Life Cycle Assessment

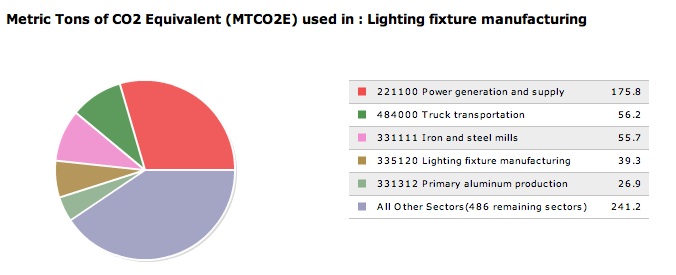

Economic Input Output Life Cycle Assessment (EIO-LCA) looks at the economics of certain sectors in order to determine environmental impact. The sector used for this product was Lighting Fixture Manufacturing. This was assumed to be a reasonable choice because “Residential-type electric lighting fixtures (except portable), including parts and accessories” combined with a couple smaller categories describing this lamp took up 21% of the sector and the remaining items listed were made from similar materials.

The numbers shown in the below graph are

(Graph created using www.eiolca.net)

Using the Purchaser Price model on the EIO-LCA website, www.eiolca.net, it can be seen that the sectors which release most of the greenhouse gasses and air pollutants associated with producing this lamp are Power Generation and Supply and Truck Transportation. This means that the materials used to produce this lamp, something that we have easy control over, does not have as much of an impact as the energy used to produce it. However, materials are in third and fifth place as CO2 emitters, so they are still very much a concern.

Therefore, the best way to reduce Greenhouse Gases would be to use a machining process that used less energy. A second tactic would be to find materials that have a less hurtful affect on the environment. Although we are unclear of exactly the type of plastics used to create the molded parts, at a guess, a more environmentally friendly plastic or metal could be used in it's stead. Making the trucking process more efficient would also help to cut down on greenhouse gasses emitted, whether this be buying more local materials or finding faster routes between cities.

Failure Mode and Effects Analysis (FMEA)

FMEA is a process by which potential failures are identified and evaluated. We have identified a number of possible failures. The most crucial being the Friction Knob, which when worn out fails to properly hold the joints in place. Another prominent problem was the Light Switch Spring, which when warn out would fail to turn the lamp on and off.

Outlined below are several problems we found concerning when analyzing this product. Please not that our RPN is an estimate.

| Item | Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility & Deadline |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Electric Cord | to transmit electricity from outlet to light bulb | loss of or no connection at plug end | lamp will not light | 8 | fault of cord manufacturer | 3 | check cords before assembly | 2 | 48 | - | controls engineer |

| fire start | 9 | fault of cord manufacturer | 1 | check cords before assembly | 2 | 18 | -reevaluate connection such that a broken connection will not start a fire | mechanical engineer | |||

| loss of or no connection at lamp end | lamp will not light | 8 | person connecting the two did a poor job | 3 | check connection after assembly | 2 | 48 | - | controls engineer | ||

| fire start | 9 | person connecting the two did a poor job | 1 | check connection after assembly | 2 | 18 | -reevaluate connection such that a broken connection will not start a fire | mechanical engineer | |||

| Non-Cord Containing Rod | to increase distance from base to light bulb | cracks in rod | rod is less strong | 3 | misuse of lamp | 5 | make rod out of a stronger material | 1 | 15 | - | customer |

| 3 | rod too thin to withstand normal use | 3 | check thickness of rods coming off assembly line (quality control) | 3 | 27 | reevaluate minimum thickness of rods | materials engineer | ||||

| rod breaks | lamp can not stay where put | 7 | misuse of lamp | 3 | make rod out of a stronger material | 2 | 42 | make sure potential uses are studied in depth | designer | ||

| Cord Containing Rod | to increase distance from base to light bulb and contain electric cord | cracks in rod | rod is less strong | 3 | misuse of lamp | 5 | make rod out of a stronger material | 1 | 15 | - | materials engineer |

| 3 | rod too thin to withstand normal use | 3 | check thickness of rods coming off assembly line (quality control) | 3 | 27 | reevaluate minimum thickness of rods | materials engineer | ||||

| rod breaks | lamp can not stay where put | 7 | misuse of lamp | 3 | make rod out of a stronger material | 2 | 42 | make sure potential uses are studied in depth | designer | ||

| wires exposed | 3 | poor job connecting end caps | 3 | quality control | 3 | 27 | - | controls engineer | |||

| Lamp Hood | to project and focus light from light bulb | Bent hood | less pretty | 4 | lamp falling to the floor or otherwise being mishandled | 5 | make hood out of stronger material | 1 | 20 | - | materials engineer |

| Base | to mount lamp on a flat surface | cracks | lamp will attach poorly to desk | 7 | too much force used when clamping lamp | 5 | run tests to see how much force will break lamp | 3 | 105 | redesign part such that it can withstand more force | mechanical engineer |

| Base Clamp | to hold base onto a flat surface | cracks | lamp will attach poorly to desk | 7 | too much force used when clamping lamp | 5 | run tests to see how much force will break lamp | 3 | 105 | redesign part such that it can withstand more force | mechanical engineer |

| Friction Knob | to tighten joints and hold joints in place | no longer holds joints in place | lamp will not stay where put | 7 | fatigue | 8 | Failure observed by user | 3 | 168 | redesign friction knob for longer lifespan | mechanical engineer |

| 7 | user turning it too tightly and then forcing joints to move | 6 | Failure observed by user | 3 | 126 | redesign friction knob for longer lifespan | mechanical engineer | ||||

| Light Bulb Socket | to connect light bulb to lamp and power | electrical failure | lamp will not turn on | 8 | poorly poured ceramics | 2 | quality control | 5 | 80 | - | controls engineer |

| 8 | wires disconnect | 3 | quality control | 5 | 120 | redesign light bulb socket such that failing to properly connect the wires is difficult | mechanical engineer | ||||

| Light Switch Spring | to hold light switch in on/off positions | spring becomes tired and will no longer work | light won't turn on/off | 7 | fatigue | 5 | Failure observed by user | 3 | 105 | redesign spring for longer lifespan | mechanical engineer |

Each potential failure is looked at based on the severity of the problem (S), it’s occurrence (O), and how easy it is to detect (D). For each of these criteria, a number is assigned between one and ten. One is always the ‘good’ side of the spectrum: the problem is not severe, the occurrence is rare, and it is easy to detect. Ten is the ‘bad’ side of the spectrum. Multiplied together, these numbers form the Risk Priority Number (RPN). A higher RPN means that problem is more of a risk.

Team Member Roles

We divided up the work of this report as follows:

- Adam Aaron: System Function and Mechanical Analysis

- Gwendolyn Barr: Design For X, Life Cycle Assessment, and Failure Mode and Effects Analysis

- Raysel Martinez: Stakeholders and Use of Lamp

- Ella Swearingen: Components and Executive Summary

We each shared our parts with the other team members, so as to come to a full understanding of the product.