Crossbow

From DDL Wiki

Contents |

Executive Summary

Our team elected to dissect a cross bow with the hopes of revitalizing this unique weapons system. The cross bow dates back to the 5th century BC in both Europe and Asia (Wagner and Campbell), and was a major development to one of the first forms of warfare technology, the bow and arrow which dates back to 9000 BC (Collins). Once the dissection of our crossbow occurred an in depth analysis of DFMA, DFE, FMEA, bill of materials and product use were analyzed.

This product has many uses and a large market ranging from collectors, to hunters to enthusiasts and each group is looking for something different. Whether it is a high quality piece to put on a wall, or a heavy duty product to trek into the backcountry for a hunt, or to be light and portable and assemble, disassemble and reassemble in a flash. As such, the design parameters for each potential user is different and finding a happy medium is important to the overall updated design.

The modern crossbow has several unique subsystems; each have a lot of moving parts. As such, there are numerous modes of failure that have to be addressed ranging from the trigger mechanism to the loading mechanism. From there, each unique mechanism has a series of potential failures. Furthering the discussion of uniqueness of these separate systems it affords very little room for standardizing components. This makes both manufacturing and also bill of materials very complicated. Our goal is to focus on improving specific elements within these mechanisms with the hope of creating a more complete and reliable crossbow be used for effectively.

During the aforementioned analyses it was found that, in the context of the crossbow, the dominant source of greenhouse gas emissions are developed during its production. This is furthered by the fact that most emissions in the sporting and athletic goods sector (which crossbows fall into) are indirect. This implies that smarter choice of materials that have less front end pollution and have less long term implications on the environment are a primary concern.

Major Stakeholders

In the context of the weapons market, crossbows are a niche product in that space accounting for here in the US. This weapon was previously used heavily in military action, but has since dwindled in developed countries and is pretty limited to underdeveloped third world uses and not front line uses. Some of China’s riot tactics employ crossbows in addition to unique special forces regimens for quiet tactics at close range like the Spanish Green Berets. Because of its scaled back military use our initial approach is to target the largest crossbow user interface: hunting and leisure. Twenty five years ago cross bows were not even allowed for hunting in most states and now the total count is 231; as this number is rising due to the versatility afforded to cross bow users in increment weather.

Consumers

- Cost

- Ergonomic

- Portable

- Weight

- Aesthetic

- Accuracy

- Reliable

- Ease of Use

- Ease of Repair

- Reloading

- Ease of storage

- Ease of packing

- Easy transformable (i.e. snap on/off)

- Durability

- Quality

Retailers

- Cost

- Overhead

- Storability

- Shelf Life

- Quality of product

- Usability of product for customers (if 23 states are ok with it for hunting, 27 are still not)

- Service center

Manufacturers

- Reliable service

- Quality control

- Materials

- Longevity

- Accuracy

- Weight

- Ease of packaging

- Ease of use

- Dynamic function

- Portable

- Folding

- Loading mechanism

- Multiple functions

- Wasted material

Product Use

The Inferno Fury 175lb. draw weight came with the limb detached to provide for better packaging. To attach the limb, place the limb through proper hole on the base, and secure using the limb securing screw. Once secured, attach the string by bending the limb and placing the string over the string holders at the ends of the limb.

Loading the Crossbow

Current crossbows require it to be reloaded each time a bolt is fired. When loading the crossbow, the foot hook is placed on the ground with the stock pointed to the sky. A cocking device is used to decrease the amount of force required to cock the bow. To use the cocking device, place the hooks of the pulleys so that the string of the device runs from the hand, to the crossbow string, around the groove in the stock, back to the crossbow string, and to the other hand. Once placed on the string, pull on the device until a loud click is audible. The loud click means that the string is securely cocked. Once securely cocked, place the odd color fletching of the bolt in the groove of the base. Push the bold back towards the string until the nock is fully against the string. The crossbow is not fully loaded.

Firing the Crossbow

Proper stance is paramount to accurate and safe use of the crossbow. To get a proper stance, stand should with apart with feet slightly staggered. Point the left hip for right handed shooter toward the target. Lean towards the target slightly. Once in the proper stance, seat the crossbow by place the stock firmly against the shoulder. Raise the crossbow to achieve vision through the sites. Look through the scope, or use the iron sites to aim at the target. Once the target is in the sites, remove the safety by pushing forward on the safety slide. Pull the trigger to fire the crossbow.

Use Study

Once the crossbow is assembled, there are a few ways which it could be misused. The most common mistake is dry firing. Dry firing is a term used for firing a weapon without any ammunition loaded. In the case of the crossbow, this occurs when the crossbow is cocked and fired without the bolt loaded. Dry firing a crossbow is very mechanically damaging to the bow. Devices have been made to mimic ammunition for the allowing of dry firing. Possible damage due to dry firing includes but is not limited to:

- String snapping

- Limb breaking

- Cam (on compound bows) breaking

- Undetectable damage

Even with a properly used crossbow, there are a few issues that users may experience. In general, these are a few complaints that customers have had:

- Intensive reloading

- Must be on ground

- Must hold arrows in quiver

- High draw weight (175 lbs.)

- Loud clicking noise once cocked

- Process takes a long time to be ready to shoot again

- Unknown if held level

- Slight recoil

- Loud shot sound comparative to other crossbows

From this list, most complaints seem to be about the loading process, but all of the complaints should be taken into consideration for the redesign.

Assembly with Parts Labeled

Mechanical Functioning

A crossbow has two main mechanical systems, a string and limb system and the trigger mechanism.

Limb String System

The first system is the mechanical system of the limb and string. In this system, the user pulls back on the string and locks it back, bending the limb. The work done by the user is converted into potential energy stored in the limb, like a giant spring. When pulling the trigger of the crossbow, this potential energy is converted into the kinetic energy causing the bolt to accelerate.

Trigger Mechanism

The second system is the mechanical system of the trigger mechanism. The trigger mechanism involves seven main parts, the firing block, a torsional spring, the intermediate trigger, the trigger, the safety pin, the safety spring, and the safety slide. In the unloaded position, a torsional spring keeps the firing block forward with the bottom of it rest in the intermediate trigger curve. To load the crossbow, the user pulls the string back until it pushes the top firing block back far enough that the bottom of the firing block slips off the intermediate trigger, similar to what is seen in the disassembled trigger mechanism photo. In the process, the user also pushes the safety slide back causing it to cover the safety pin. With the safety slide pushed back, the safety pin is not allowed to move up if the trigger is pulled and therefore will not allow the trigger to move the intermediate trigger enough to allow the firing block to rotate. To allow firing of the crossbow, the safety slide has to be pushed forward, allowing the safety pin to move,enabling the trigger to be fully pulled, pushing up the intermediate trigger, and allowing the firing block to rotate, releasing the bolt.

Bill of Materials

| Part Number | Description | Quantity | Weight (oz) | Function | Material | Manufacturing Process | Image |

|---|---|---|---|---|---|---|---|

| 1 | Foot Hook | 1 | 4.054 | Support for loading | Steel | Bent | |

| 2 | Foot Hook Screw | 2 | 0.188 | Attaches foot hook to base | Steel | Upset Forged | |

| 3 | Limb Tightening Bolt | 1 | 0.259 | Secures limb | Steel | Upset Forged | |

| 4 | Screw Block | 1 | 0.85 | Increases surface area of tightening bolt | Steel | Extruded | |

| 5 | Front Limb Barrier | 1 | 0.1 | Prevents metal to metal contact | Plastic | Injection Molded | |

| 6 | Limb | 1 | 8.607 | Produces force for firing | Fiberglass | Molded | |

| 7 | Sting Holder | 2 | 0.0975 | Attaches string to end of the limb | Plastic | Injection Molded | |

| 8 | String | 1 | 0.388 | Transmits force from limb to bolt | Fabric | Twisted | |

| 9 | Back Limb Barrier | 1 | 0.123 | Prevents metal to metal contact | Plastic | Injection Molded | |

| 10 | Base | 1 | 34.85 | Chassis for all of crossbow parts | Aluminum | Injection Molded | |

| 11 | Quiver Holder | 1 | 0.3175 | Provides attachment for quiver | Plastic | Injection Molded | |

| 12 | Quiver Attachment Screw | 2 | 0.0725 | Attaches quiver holder to base | Steel | Upset Forged | |

| 13 | Front Sling Bolt | 1 | 0.26 | Provides attachment for sling | Steel | Upset Forged | |

| 14 | Front Sling Spacer | 1 | 0.1 | Extends front sling bolt | Plastic | Extruded | |

| 15 | Grip | 1 | 4.33 | Provides holding area for user to grip base | Plastic | Injection Molded | |

| 16 | Grip Screw | 2 | 0.1225 | Attaches grip to base | Steel | Upset Forged | |

| 17 | Safety Slide | 1 | 0.5165 | Prevents from misfire | Steel | Stamped | |

| 18 | Ball Bearing | 2 | 0.008 | Allows smooth rolling surface | Stainless Steel | De-flashing | |

| 19 | Safety Spring | 1 | 0.004 | Pushes ball bearing against safety slide to allow from low tolerance sliding surface | Steel | Extruded and Coiled | |

| 20 | Left Trigger Casing | 1 | 2 | Provides housing for trigger sub assembly | Aluminum | Injection Molded | |

| 21 | Pin Spring | 1 | 0.0175 | Keeps pin down until used | Steel | Extruded and Coiled | |

| 22 | Torsional Spring | 1 | 0.004 | Keeps firing block forward until cocked | Steel | Extruded and Coiled | |

| 23 | Firing Block | 1 | 0.914 | Holds arrow back when cocked | Steel | Stamped | |

| 24 | Plastic 6mm Stop | 1 | 0.01 | Prevents from metal to metal contact | Plastic | Extrusion | |

| 25 | Safety Pin | 1 | 0.07 | Mechanical stop when safety is on | Aluminum | Extruded | |

| 26 | Intermediate Trigger | 1 | 0.632 | Transmits force from trigger to firing block | Steel | Stamped | |

| 27 | Trigger | 1 | 0.792 | User interface to fire crossbow | Steel | Stamped | |

| 28 | Right Trigger Casing | 1 | 1.217 | Provides housing for trigger sub assembly | Aluminum | Injection Molded | |

| 29 | Trigger Pin | 3 | 0.08 | Provides axes for trigger components to rotate around | Steel | Extruded | |

| 30 | Spring Pin | 2 | 0.0695 | Attaches trigger casings to base | Steel | Extruded | |

| 31 | Logo Sticker | 2 | 0.034 | Provides branding and covers spring pins | Plastic | Injection Molded | |

| 32 | Stock Attachment Screw | 1 | 0.337 | Attaches stock to base | Steel | Upset Forged | |

| 33 | Stock Attachment Washer | 1 | 0.1345 | Increases head area of stock attachment screw | Steel | Stamped | |

| 34 | Scope Adjustment Knob | 1 | 0.077 | Adjustment for scope assembly | Plastic | Injection Molded | |

| 35 | Bolt Spring Screw | 2 | 0.0166 | Attaches bolt spring to bolt guide | Steel | Upset Forged | |

| 36 | Bolt Spring | 1 | 0.1525 | Holds bolt down against base | Steel | Extruded and Coiled | |

| 37 | Bolt Guide | 1 | 6.89 | Covers trigger assembly and provides attachment for scope sub assembly | Steel | Injection Molded | |

| 38 | Adjustment Knob Snap Washer | 1 | 0.005 | Prevents knob from falling off | Steel | Stamped | |

| 39 | Ball Bearing Spring | 1 | 0.0075 | Provides stability for scope sub assembly | Steel | Extruded and Coiled | |

| 40 | Front Bolt Washer | 1 | 0.005 | Increases surface area of front bolt head | Steel | Stamped | |

| 41 | Front Bolt | 1 | 0.092 | Attaches bolt guide to base | Steel | Upset Forged | |

| 42 | Back Screw | 1 | 0.114 | Attaches bolt guide to base | Steel | Upset Forged | |

| 43 | Scope Sub-assembly | 1 | 4.8 | Provides upgraded sighting for crossbow | Composite | Assembled | |

| 44 | Stock-Base Separator | 1 | 0.061 | Decreases need for tight tolerances between stock and base | Plastic | Stamped | |

| 45 | Stock | 1 | 20.8816 | Provides user interface to properly hold crossbow | Plastic | Injection Molded | |

| 46 | Back Strap Screw | 1 | 0.25 | Provides attachment for sling | Steel | Upset Forged | |

| 47 | Clasp Ring | 2 | .091 | Provides attachment to strap | Steel | Extruded and Bent | |

| 48 | Clasp Knob | 2 | .052 | Provides tightening mechanism | Steel | Extruded and Machined | |

| 49 | Clasp Screw Pin | 2 | .043 | Provides tightening mechanism | Steel | Extruded and Machined | |

| 50 | Clasp Spring | 2 | .013 | Forces clasp close in steady state | Steel | Extruded and Coiled | |

| 51 | Clasp Base | 2 | .174 | Provides structure to clasp | Steel | Injection Molded | |

| 52 | Clasp Closure | 2 | .075 | Closes clasp | Steel | Stamped | |

| 53 | Long Strap | 1 | .164 | Provides length to the strap | Nylon | Off the Shelf | |

| 54 | Adjustment Buckle | 1 | .152 | Allows for adjustment to the length of the strap | Steel | Stamped and Bent | |

| 55 | Attachment Buckle | 2 | .123 | Provides attachment from short strap to long strap | Steel | Stamped and Bent | |

| 56 | Short Strap | 2 | .094 | Connects cushioning section to long adjustable strap | Nylon | Off the Shelf | |

| 57 | Strap Finishing Cap | 2 | .112 | Provides structure and good finished appearance | Plastic | Injection Molded | |

| 58 | Strap Cushioning Cover | 1 | .056 | Provides comfortable material for should strap | Fabric | Off the Shelf | |

| 59 | Cushioning Foam | 1 | .085 | Provides cushion to the strap | Plastic Foam | Off the Shelf | |

| 60 | Strap Finishing Strip | 1 | .092 | Hides connection seem in cushioned part of strap | Leather | Off the Shelf |

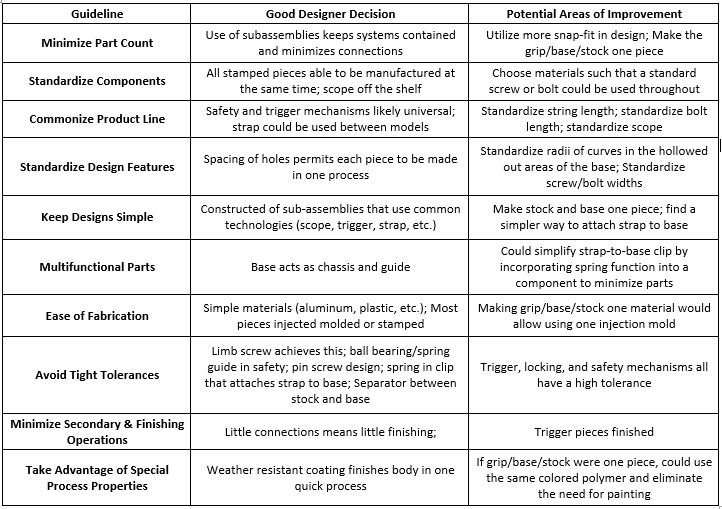

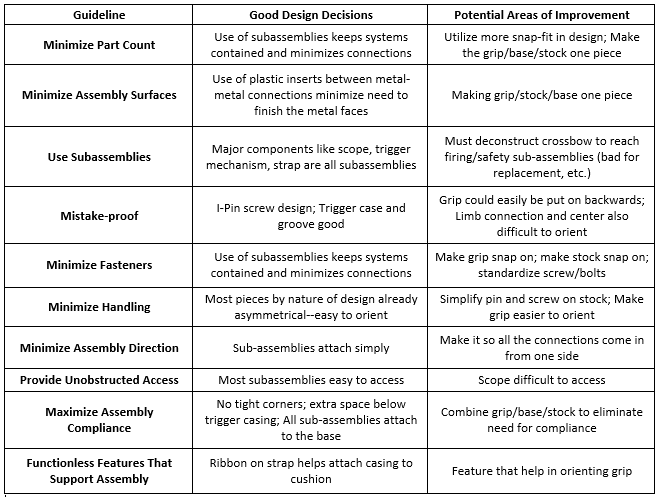

Design for Manufacture and Assembly (DFMA)

For successful and safe use, the design of a crossbow must allow several distinct functions. An arrow needs to be loaded and locked and a trigger must be able to release it, a safety mechanism should prevent misfires, a scope allows aim, and the strap allows easy transport. We found when dissecting the crossbow that each of these functions had its own sub-assembly. In fact, we realized that the entire crossbow could be considered one large collection of sub-assemblies.

For the most part, we decided that for this type of crossbow (deer and turkey hunting grade) the sub-assemblies themselves were fairly efficient and appropriately designed. Because each sub-assembly and their components are so unique, standardizing components between them made little sense. We felt then that the best areas of improvements were in the connections between the sub-assemblies. Most of our DFMA analysis looks to simplify these connections.

DFM

DFA

Failure Modes and Effects Analysis (FMEA)

After analyzing the different failure modes, we have concluded that failure of any sub-assembly could result in serious user injury. This is due to the fact that each sub-assembly is responsible for holding the high potential energy of the bow and only releasing this energy on the proper components when the user desires. However, having said this, we can say that many of these risks have a low likeliness of occurring if the manufacturer maintains a decent build quality and regularly inspects components and sub-assemblies. On the user end, the risks can be kept low if the user uses the product as it was intended and regularly inspects the components for wear.

We recommend that additional safety features be put into place such as an anti-dry firing mechanism to make the crossbow fool-proof or making the cocking device out of a stronger material (metal).

Some failure modes and effects of various components of the crossbow. (S)everity, Probability of (O)ccurence and (D)ectability of Failure ratings are assigned following the standards established in Tables 14.13, 14.14 and 14.15, respectively in Dieter and Schmidt (p. 707). Risk Priority Numbers (RPN) are generated by finding the product of S x O x D.

| Item and Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions |

|---|---|---|---|---|---|---|---|---|---|

| Limbs (Stores potential energy needed to accelerate the bolt) | Fracture | User Injury / Misfire | 8 | Fatigue / Dry fire | 2 | Perform fatigue tests on limb | 8 | 128 | Inspect/replace after a certain number of fires |

| Bowstring (Accelerates bolt to target) | Fracture | User injury / Misfire | 7 | Fatigue / Wear / Dry fire | 5 | Perform stress/fatigue tests on string | 3 | 105 | Inspect string for any signs of fraying |

| Locking mechanism (Locks bowstring in tension to prepare for firing) | Fail to lock string | Non-operable / Instability / Misfire | 6 | Component wear / Dimensions out of spec | 3 | Check if it locks | 2 | 36 | Rework tolerances / Inspect subassembly for loose fitting or broken parts |

| Cocking device (Makes it easier to cock the crossbow) | Fracture | Limb or String fracture / user injury | 8 | Plastic deformation caused by wear or excessive load | 6 | Perform stress / fatigue tests on device | 4 | 192 | Change to stronger material |

| Trigger mechanism (Releases the tension on the bowstring) | Trigger does not fire | Misfire | 6 | Component wear / Dimension out of spec | 5 | Check if parts fit together well | 2 | 60 | Rework tolerances / Inspect subassembly for loose fitting or broken parts |

| Safety mechanism (Prevents the accidental fire of crossbow) | Will not disable trigger | Injury to user or bystander | 6 | Component wear | 3 | Check if it locks | 2 | 36 | Check for signs of wear / Replace if wear is visible |

DFE Analysis

| DFE Guideline | Good Aspects of Competitor Product and Ideas for Improvement |

|---|---|

| 0. New Concept Development | Remove fasteners to allow a snap-fit design.

Integrate a quiver into the crossbow itself, instead of having it as a separate part. Add a loading mechanism that does not require a very significant force input from the user. |

| 1. Select Low Impact Materials | Crossbow:

Aluminum, Fiberglass, Steel Bolt: Aluminum, Carbon Fiber Sling: Nylon, Foam

|

| 2. Reduce Material Amount | Slots in the crossbow body reduce mass

Limb is removable to reduce transport volume The "snap-fit" design would reduce material amount by removing the need for fasteners |

| 3. Eco-Manufacturing | Camouflage is wrapped, but powder coating may offer some advantages.

Manufacturing requires no welding or soldering. Very little machining is used. The body is manufactured via injection molding, as evidenced by visible injection pins. Using recycled aluminum instead of virgin aluminum may offer energy savings. |

| 4. Optimize Distribution | Packaging is very minimalistic. |

| 5. Reduce Use-Phase Impact | Crossbow is human-powered using potential energy.

All parts are reusable. |

| 6. Maximize The First Life | Reliability and durability are increased by having a very simple design.

Scope and scope accessories are easily replaceable, but the device still has room for improvement regarding modularity. The grip and stock could be more easily removable. |

| 7. End of Life | Crossbow and bolts are either retired or discarded. |

Product Life Cycle Analysis

| Life Cycle Stage | Description | Inputs | Outputs |

|---|---|---|---|

| Material Extraction |

Raw materials are processed and made into materials that can be used for manufacturing. |

Iron Ore Aluminum Ore Petroleum Silica sand Limestone Polyacrylonitrile (synthetic) |

Steel Aluminum Fiberglass Plastic Carbon Fiber |

|

Production

|

Manufacturing materials are made into components. |

Steel Aluminum Fiberglass Plastic Carbon Fiber | Components |

| Use |

Archery, Hunting | Crossbow, Bolts | Shooting Crossbow |

| End of Life | Retiring/Disposal | Crossbow, Bolts | Landfill |

| Transportation | Airplane, Boat, Truck | Fuel, Crossbow, Bolts | Crossbow, Bolts |

EIOCLA

The economic input-output life cycle assessment (EIOCLA) was used to determine the environmental impact of the production of an individual crossbow and to gauge whether or not a CO2 tax would affect the economics of this product. A baseline economic activity of $1,000,000 was used for data generation and then later scaled down in order to generate more relatable data.

| Item | Crossbow | Bolts |

|---|---|---|

| Sector # and Name | 339920

Sporting and athletic goods manufacturing | 339920

Sporting and athletic goods manufacturing |

| Reference Unit | 1 crossbow | 1 bolt |

| Units consumed per product life | 1 crossbow | 6 bolts |

| Retail cost per unit (2002) | $121.00 | $25.70 |

| Lifetime cost | $121.00 | $25.70 |

| Sector mtCO2e Per $1M | 613 tons | 613 tons |

| Implied mtCO2e per Product Life | 0.074 tons | 0.016 tons |

| CO2 Tax @ $30/mtCO2e | $2.23 | $0.47 |

DFE Conclusions

- The dominant source of GHG emissions from this product stem from its production, particularly power generation and supply. Power generation and supply make up 34.1% of the Sporting and Athletic Goods Manufacturing Sector (339920).

- A $30/tCO2eq tax increase would add $2.70 to the lifetime cost of the product, which is only 1.84% of the total cost. As a result, it is fair to say that it will not affect product sales.

- Sporting goods and manufacturing are a very diverse sector, so there is a considerable amount of aggregation uncertainty.

- Most emissions related to this product are indirect, as only 3.58% of emissions come from the Sporting and Athletic Goods Manufacturing Sector (339920).

- Our design suggestions include reducing the number of parts and material amount used to make certain components. This is supported by the DFE analysis, which points to high material costs.

Team Members

- Zachary Medeiros- DFE

- Spencer Lehr - Product Use, Mechanical Function, and Bill of Materials

- Jennifer Golda - DFMA

- Nathaniel Krasnoff - Executive Summary, Major Stakeholders

- Lenny Rodriguez - FMEA

References

Dieter, George E., and Linda C. Schmidt. Engineering Design. 4th Edition. New York, NY: McGraw-Hill, 2009. Print.

Collins, Desmond (1973). Background to archaeology: Britain in its European setting (Revised ed.). Cambridge University Press. ISBN 0-521-20155-1.

Wagner, Donald B. (1993). Iron and Steel in Ancient China: Second Impression, With Corrections. Leiden: E.J. Brill. ISBN 90-04-09632-9. pp. 153, 157–158.