Soda gun

From DDL Wiki

(Difference between revisions)

(→Use Study) |

(→Bill of Materials) |

||

| Line 79: | Line 79: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_RoundHead1.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 89: | Line 89: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_EliSodaButtonTop.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 99: | Line 99: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

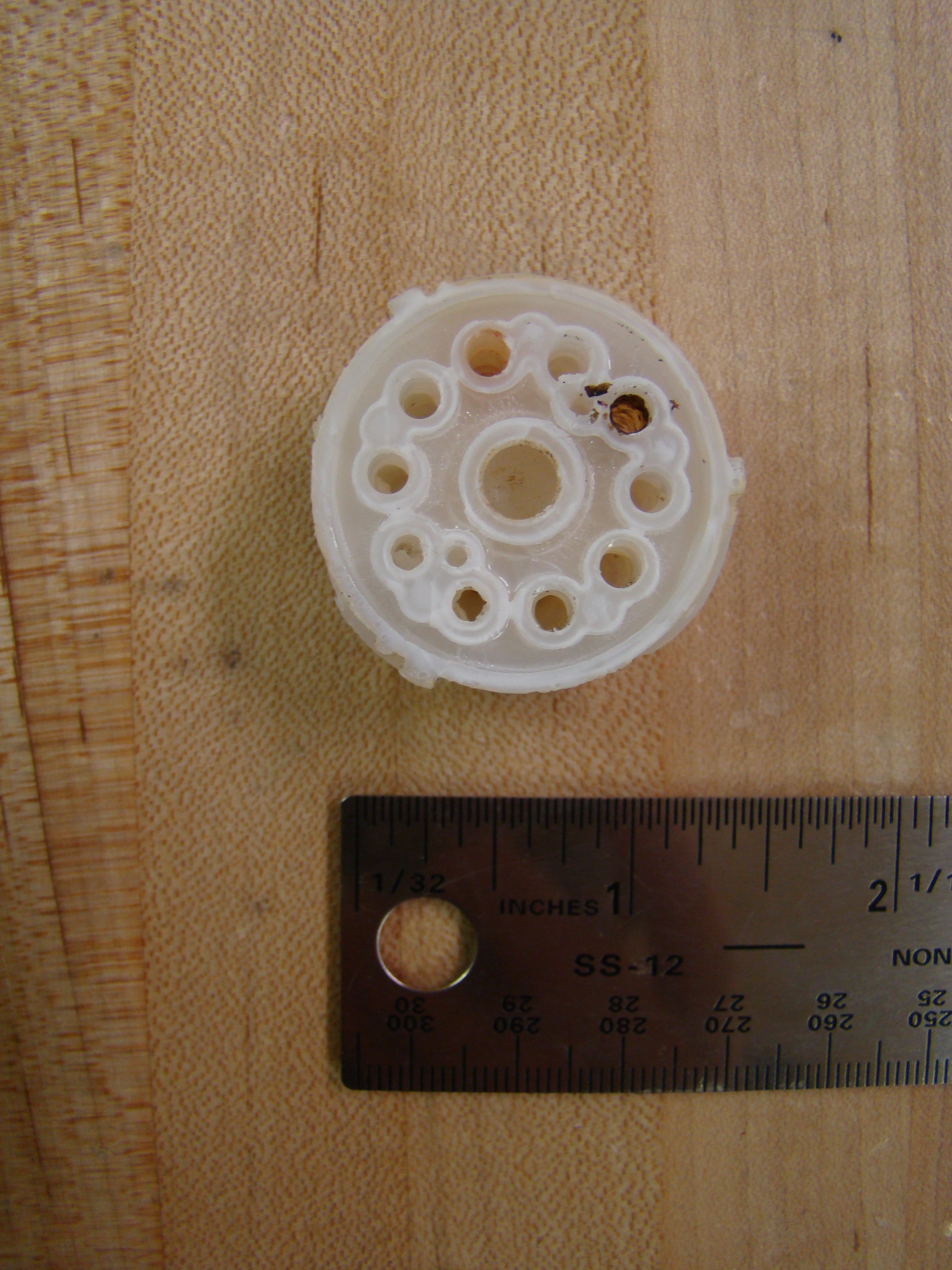

| - | | | + | |[[Image:T9S14_EliSodaButtonBot.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 109: | Line 109: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_CirSodaButtonTop.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 116: | Line 116: | ||

|8 | |8 | ||

|<1 | |<1 | ||

| - | |Translates input key | + | |Translates input key force to release soda |

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_CirSodaButtonBot.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 129: | Line 129: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_FlatHead.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 139: | Line 139: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_PlasticWasher.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 149: | Line 149: | ||

| Stainless Steel | | Stainless Steel | ||

|Die Cast, punched | |Die Cast, punched | ||

| - | | | + | |[[Image:T9S14_ButterflyClip.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 159: | Line 159: | ||

| Stainless Steel | | Stainless Steel | ||

|Die Cast, punched | |Die Cast, punched | ||

| - | | | + | |[[Image:T9S14_LargeButterflyClip.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 169: | Line 169: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

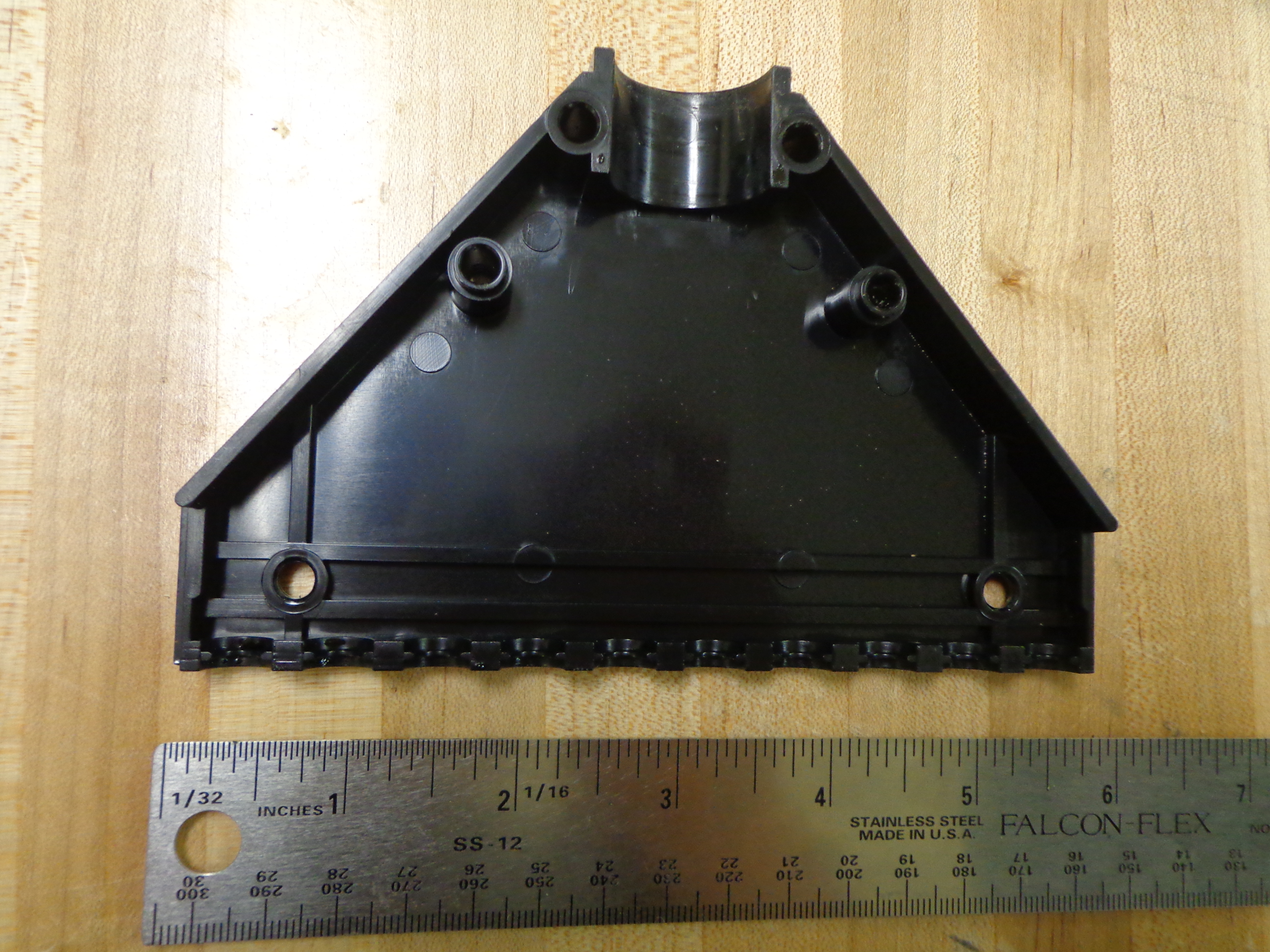

| - | | | + | |[[Image:T9S14_ButtonPanel.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 179: | Line 179: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_RoundHead2.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 189: | Line 189: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_RoundHead3.jpg]] |

|- | |- | ||

|- | |- | ||

|13 | |13 | ||

| - | |"Hexagon, 7/8" len, 1/8" dia threaded head ( | + | |"Hexagon, 7/8" len, 1/8" dia threaded head (Receives Part #11)" |

|2 | |2 | ||

|<1 | |<1 | ||

| Line 199: | Line 199: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_Hexagon.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 209: | Line 209: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_NozzleCaps.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 219: | Line 219: | ||

|Rubber | |Rubber | ||

|Std Purchase Part | |Std Purchase Part | ||

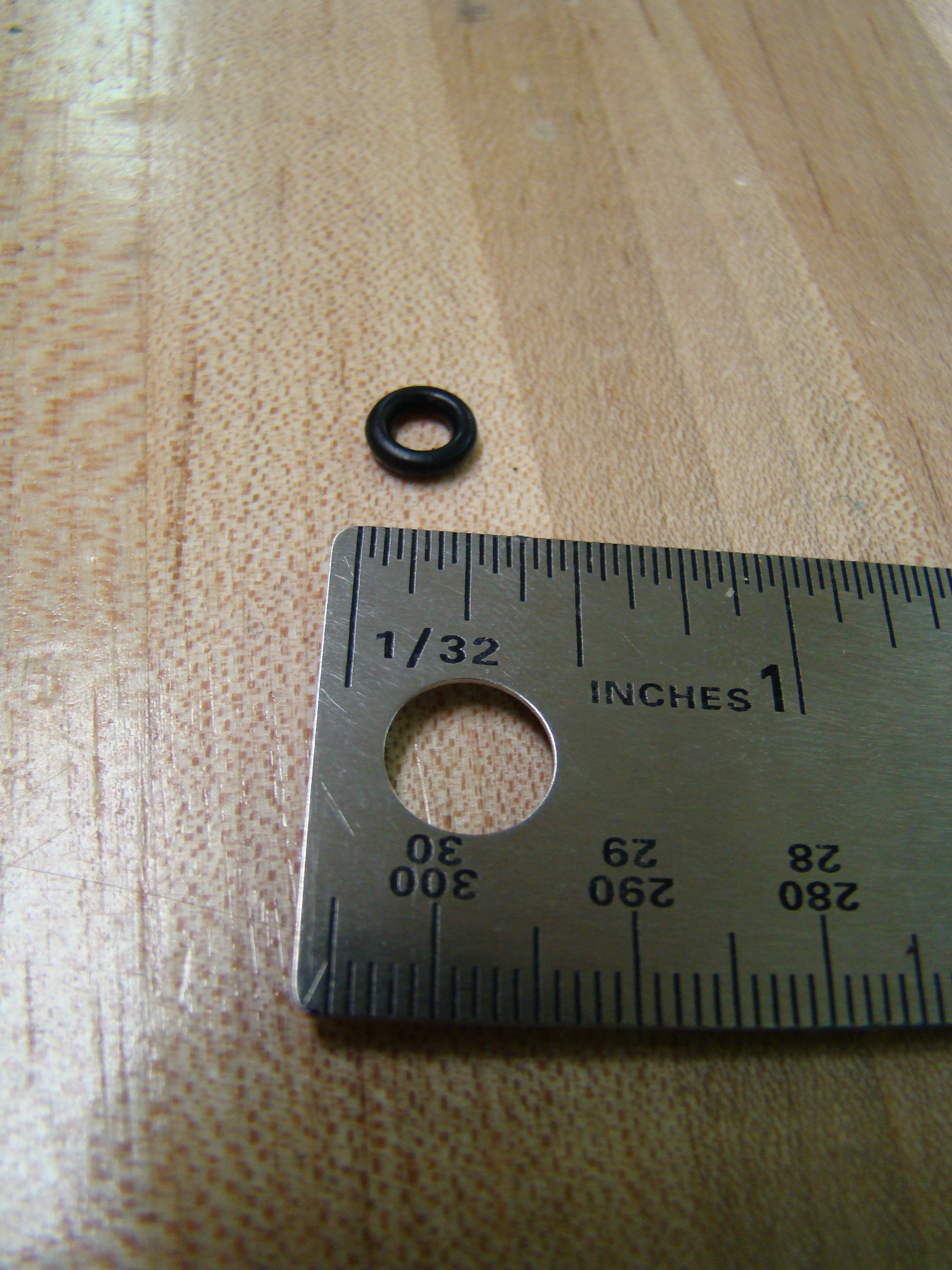

| - | | | + | |[[Image:T9S14_Oring1.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 229: | Line 229: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_RoundHead4.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 239: | Line 239: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_BackPanel.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 249: | Line 249: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

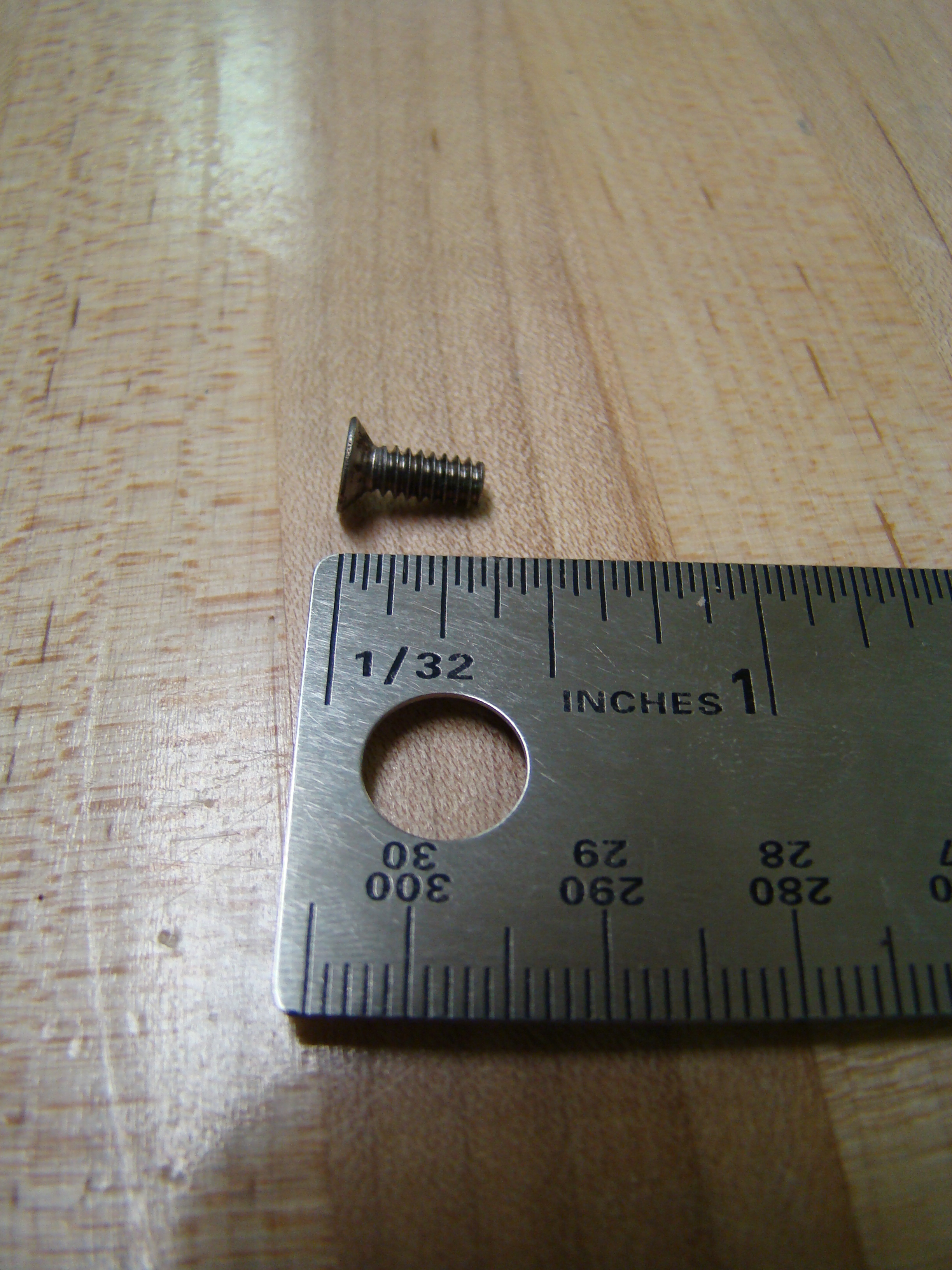

| - | | | + | |[[Image:T9S14_CustomScrew.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 259: | Line 259: | ||

|Rubber | |Rubber | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring2.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 269: | Line 269: | ||

|Rubber | |Rubber | ||

|Std Purchase Part | |Std Purchase Part | ||

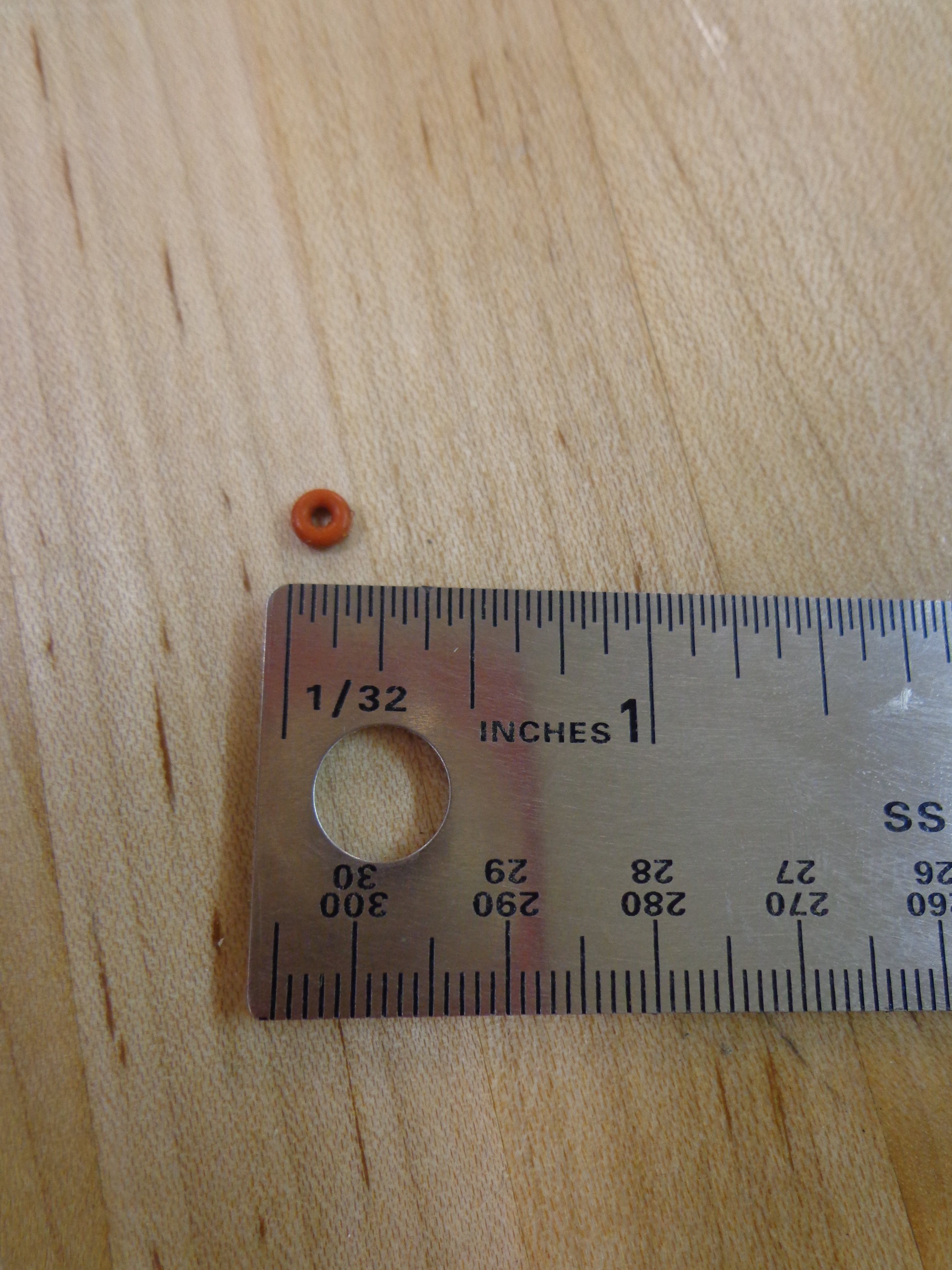

| - | | | + | |[[Image:T9S14_Oring3.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 279: | Line 279: | ||

|Plastic | |Plastic | ||

| | | | ||

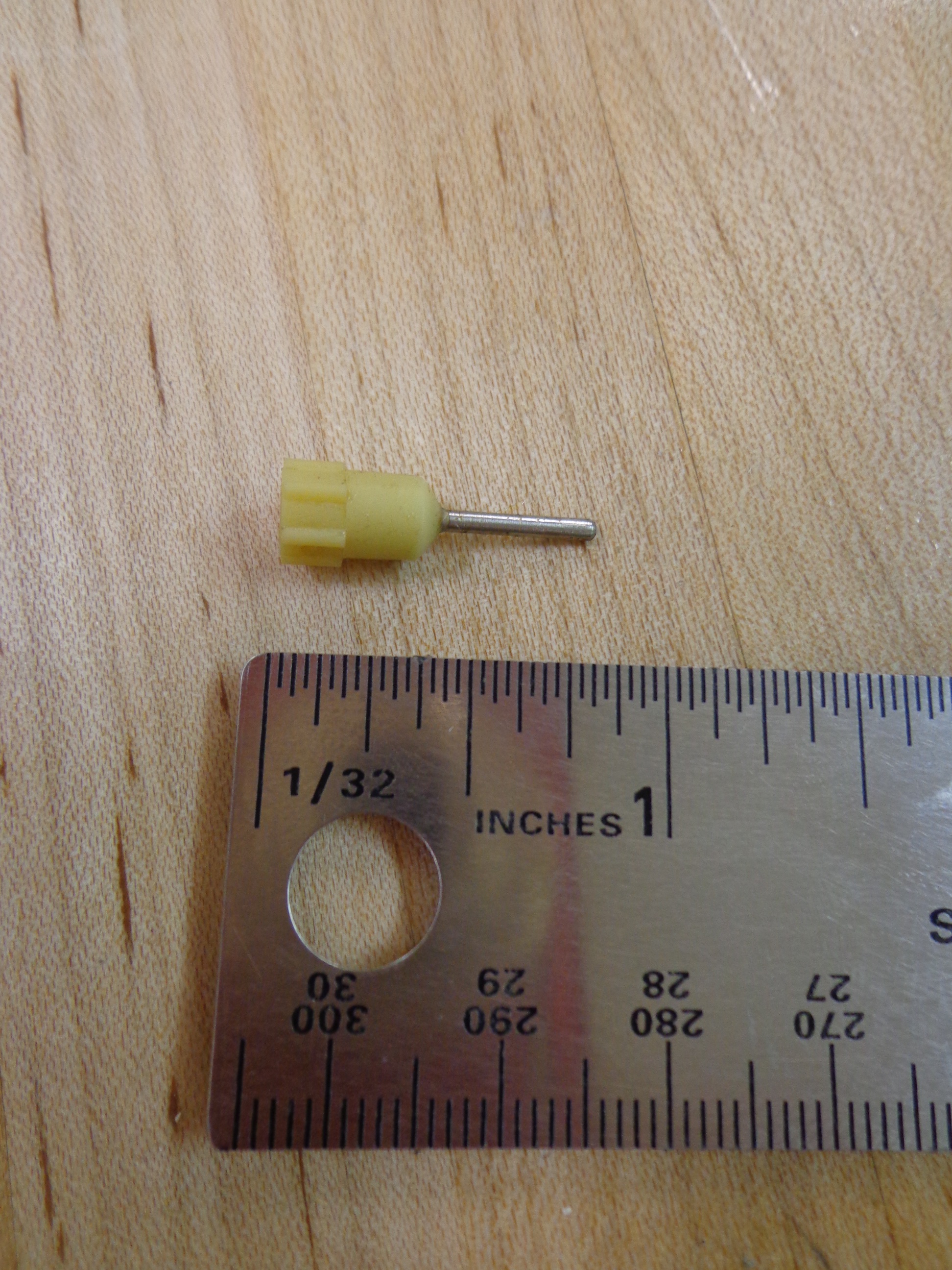

| - | | | + | |[[Image:T9S14_SpringCap.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 289: | Line 289: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_Spring.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 299: | Line 299: | ||

|Rubber | |Rubber | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring4.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 309: | Line 309: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

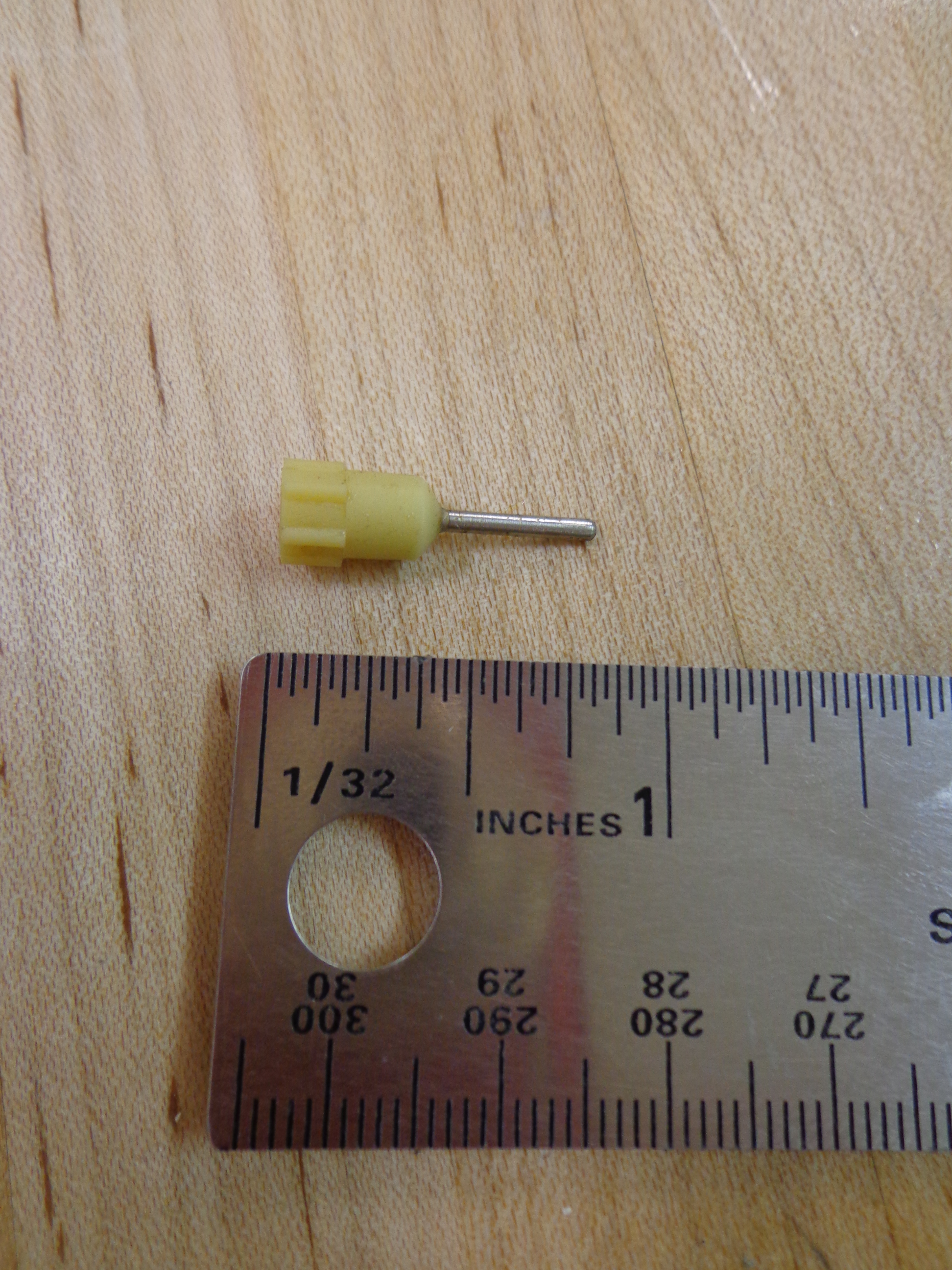

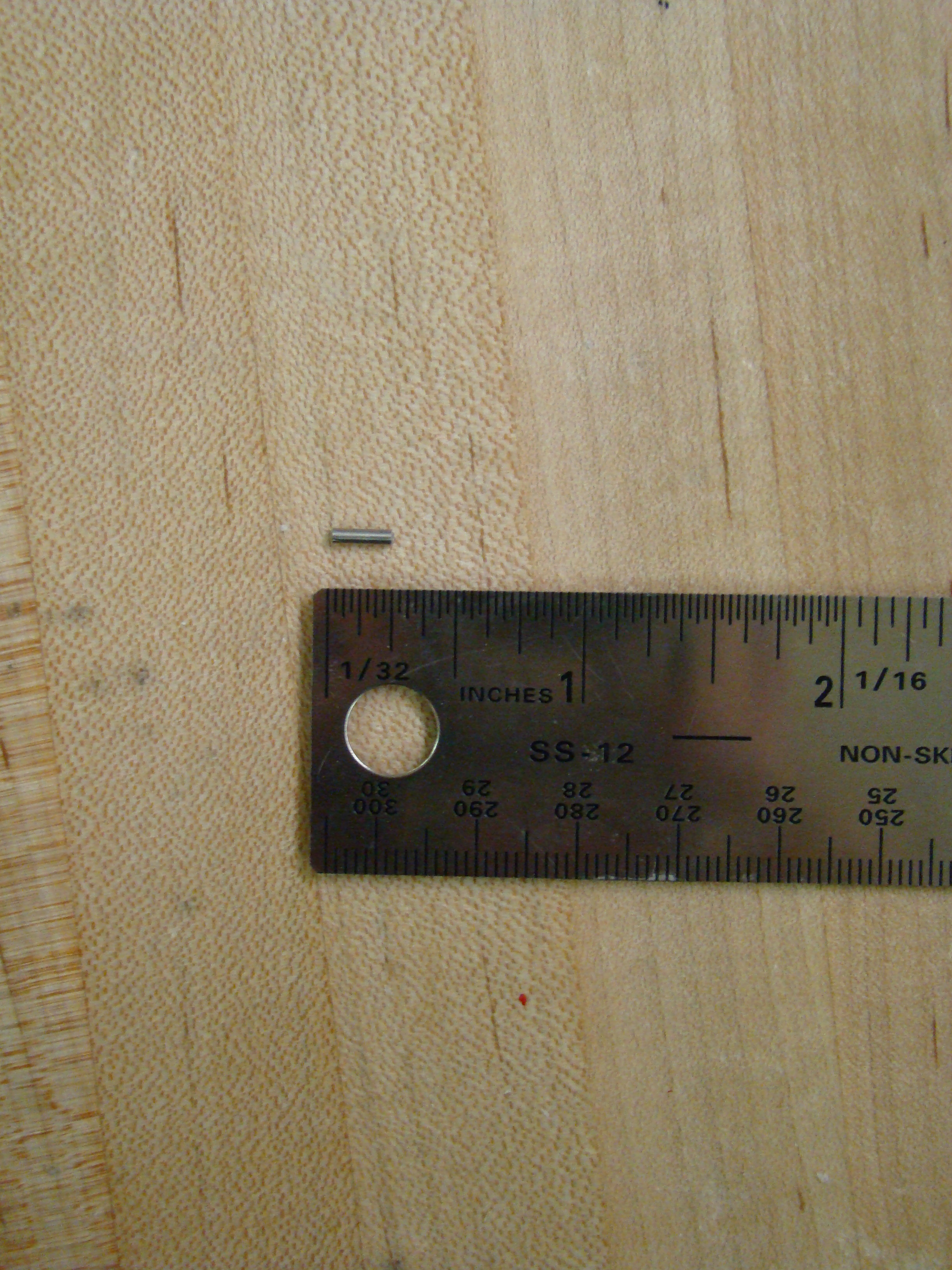

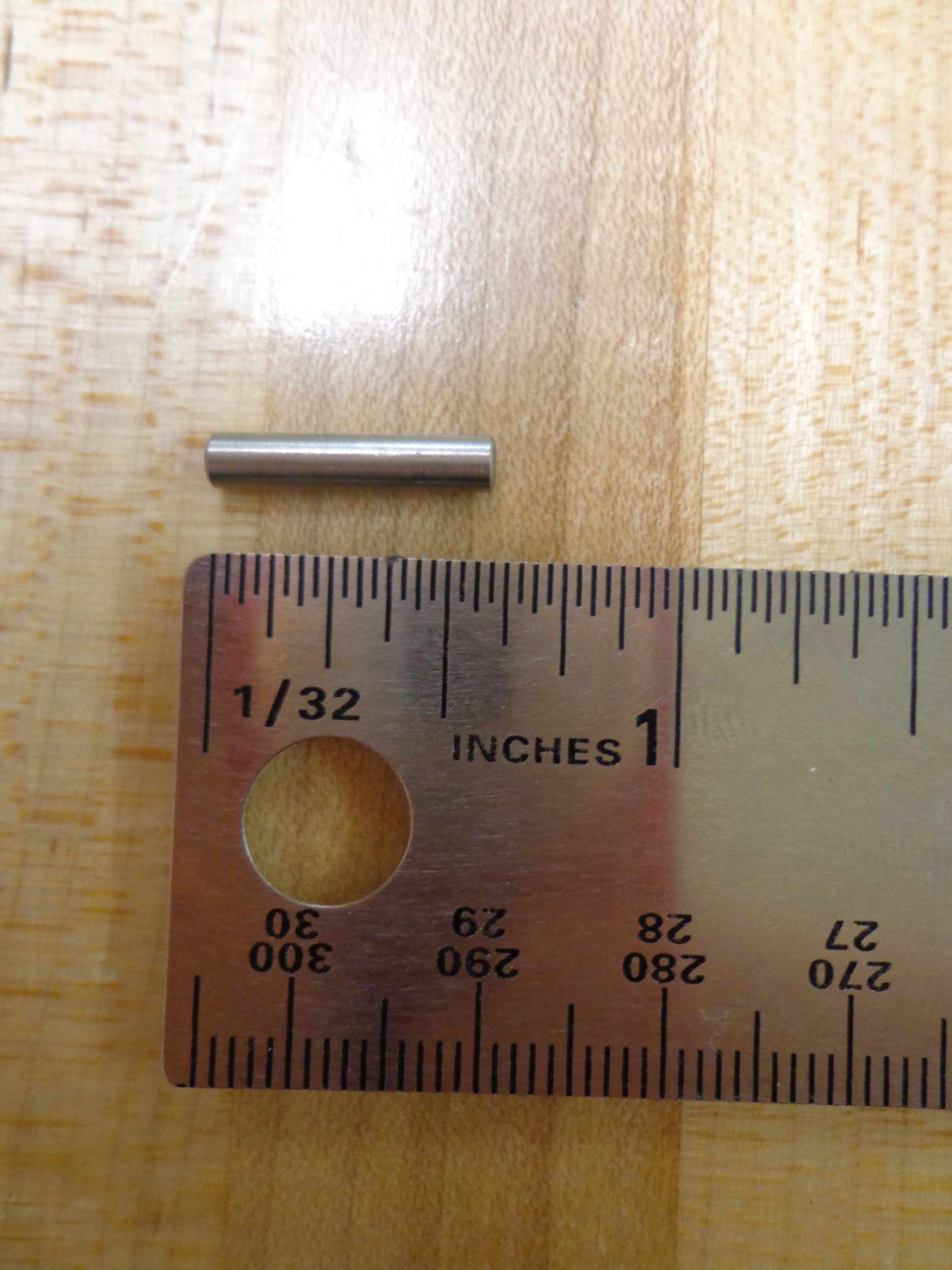

| - | | | + | |[[Image:T9S14_Pin.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 319: | Line 319: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_PlasticValve.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 329: | Line 329: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_GunNozzle.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 339: | Line 339: | ||

|Rubber | |Rubber | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring5.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 349: | Line 349: | ||

|Plastic | |Plastic | ||

|Machined in five layers, irreversibly sealed together, post-drilled | |Machined in five layers, irreversibly sealed together, post-drilled | ||

| - | | | + | |[[Image:T9S14_GunBody.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 359: | Line 359: | ||

|Plastic | |Plastic | ||

|Turned, glued to soda gun body | |Turned, glued to soda gun body | ||

| - | | | + | |[[Image:T9S14_NozzleBase.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 369: | Line 369: | ||

| Stainless Steel | | Stainless Steel | ||

|Turned | |Turned | ||

| - | | | + | |[[Image:T9S14_NozzlePins.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 379: | Line 379: | ||

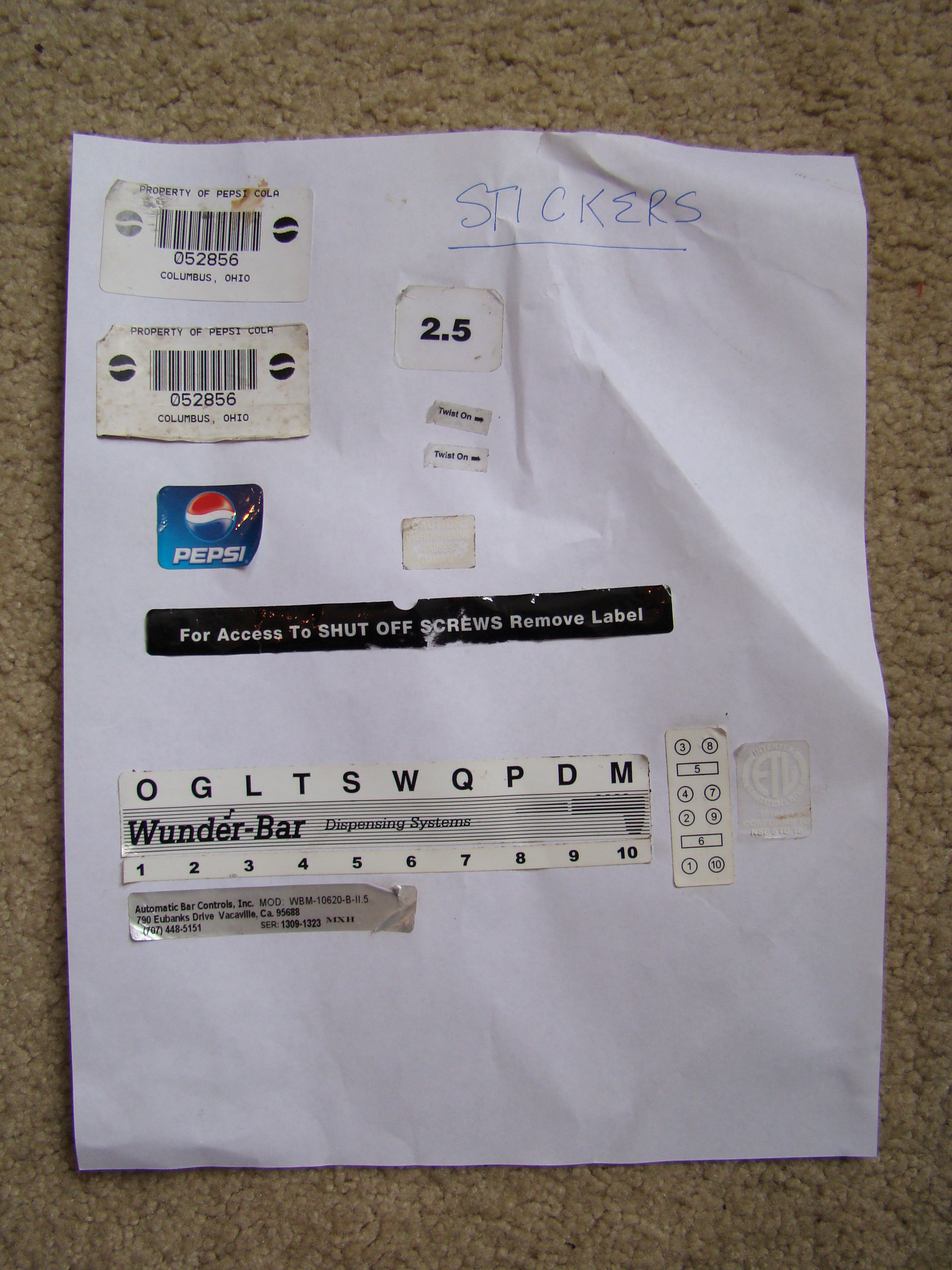

|Paper | |Paper | ||

|Printed | |Printed | ||

| - | | | + | |[[Image:T9S14_Stickers.jpg]] |

|- | |- | ||

| colspan="8" align = center| ''Flow Regulator Sub-Assembly'' | | colspan="8" align = center| ''Flow Regulator Sub-Assembly'' | ||

| Line 391: | Line 391: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_RegulatorBacking.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 401: | Line 401: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_FlatTop.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 411: | Line 411: | ||

| Stainless Steel | | Stainless Steel | ||

|Std Purchase Part | |Std Purchase Part | ||

| - | | | + | |[[Image:T9S14_TubeRetainer.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 421: | Line 421: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_MainBody.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 431: | Line 431: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_SingleHolder.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 441: | Line 441: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

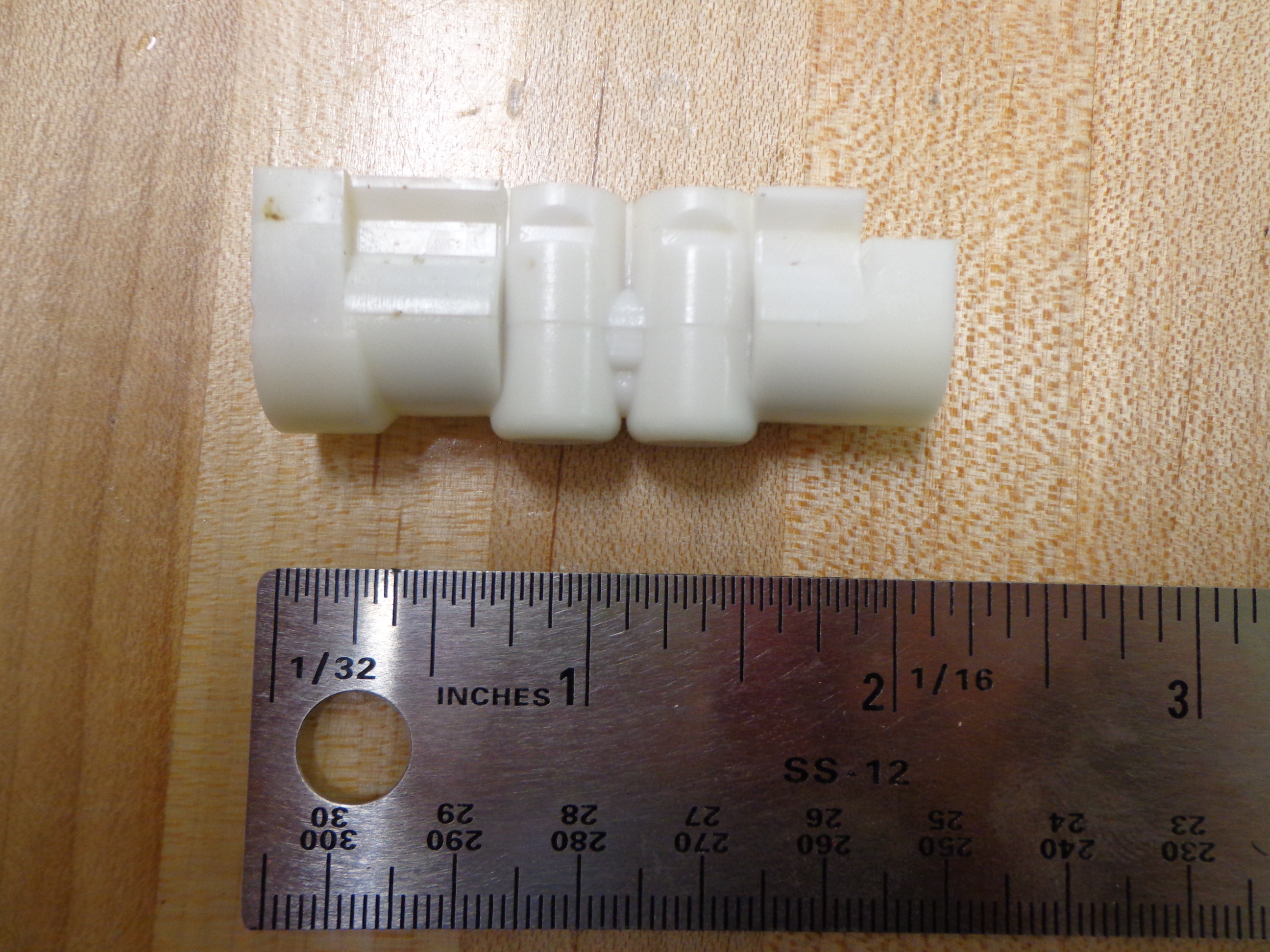

| - | | | + | |[[Image:T9S14_ShutOffScrew1.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 451: | Line 451: | ||

|Rubber | |Rubber | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_ShutOffScrew2.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 461: | Line 461: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

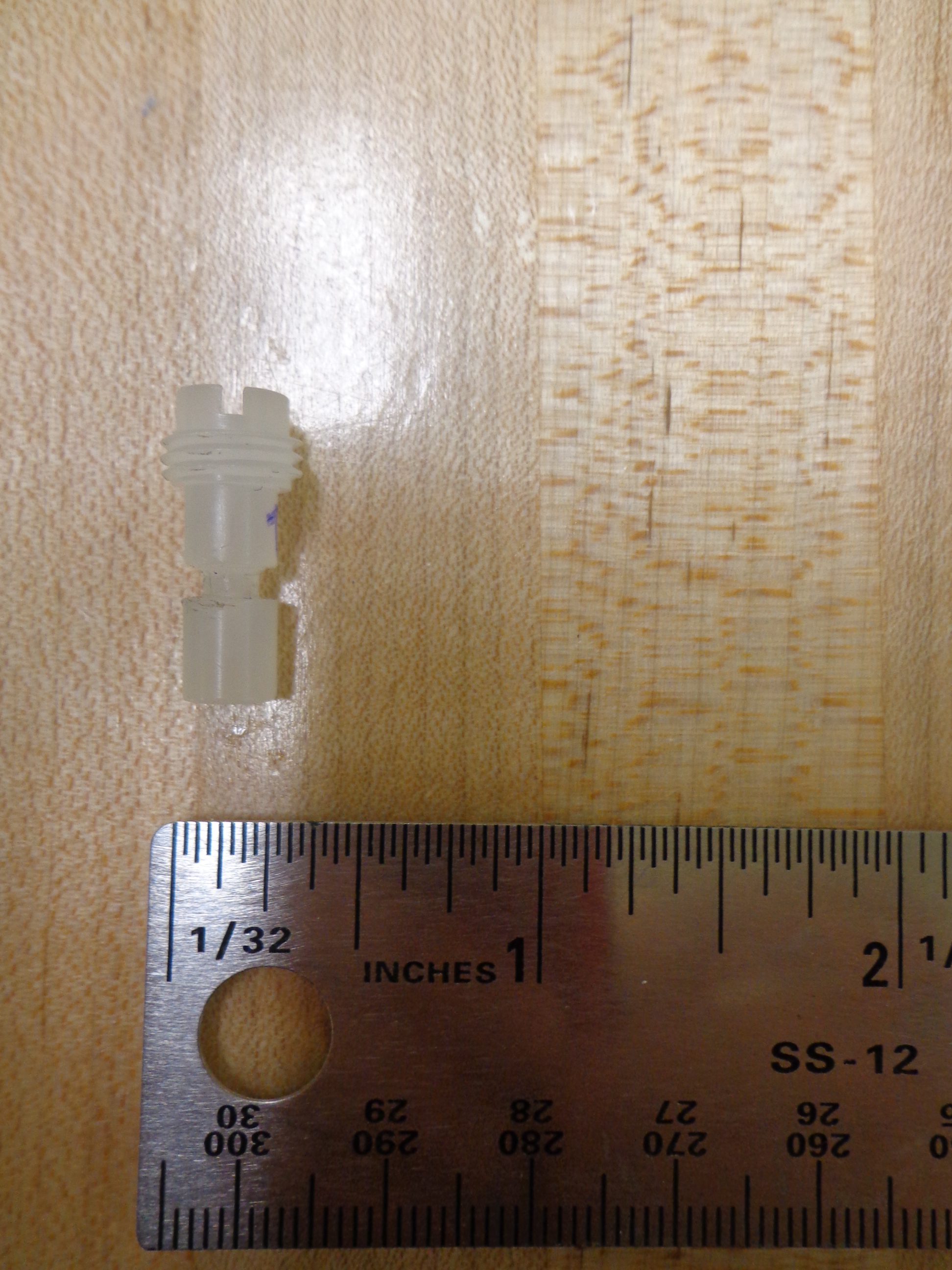

| - | | | + | |[[Image:T9S14_FlowScrew1.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 471: | Line 471: | ||

|Rubber | |Rubber | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring6.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 481: | Line 481: | ||

| Stainless Steel | | Stainless Steel | ||

|Cut to length | |Cut to length | ||

| - | | | + | |[[Image:T9S14_PinHousing.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 491: | Line 491: | ||

| Stainless Steel | | Stainless Steel | ||

|Cut to length | |Cut to length | ||

| - | | | + | |[[Image:T9S14_Pivot.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 501: | Line 501: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_RegulatorFront.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 511: | Line 511: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_Cap1.jpg]] |

|- | |- | ||

|- | |- | ||

|45 | |45 | ||

| - | |Cap of separating mechanism | + | |Cap of separating mechanism pivot |

|1 | |1 | ||

|<1 | |<1 | ||

| Line 521: | Line 521: | ||

| Stainless Steel | | Stainless Steel | ||

|Turned/Lathed | |Turned/Lathed | ||

| - | | | + | |[[Image:T9S14_Cap2.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 531: | Line 531: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_SeparatorBody.jpg]] |

|- | |- | ||

| colspan="8" align = center| ''Small Tube Sub-Assembly'' | | colspan="8" align = center| ''Small Tube Sub-Assembly'' | ||

| Line 542: | Line 542: | ||

|Plastic | |Plastic | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_SmallTube.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 552: | Line 552: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_ClampingRing.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 562: | Line 562: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_EndCap.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 572: | Line 572: | ||

|Rubber | |Rubber | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring7.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 582: | Line 582: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_PlasticRing.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 592: | Line 592: | ||

| Stainless Steel | | Stainless Steel | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_MetalTube.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 602: | Line 602: | ||

|Plastic | |Plastic | ||

|Injection Molded | |Injection Molded | ||

| - | | | + | |[[Image:T9S14_BaseConnector.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 612: | Line 612: | ||

| Stainless Steel | | Stainless Steel | ||

|Cut, stamped | |Cut, stamped | ||

| - | | | + | |[[Image:T9S14_HoldingPlate.jpg]] |

|- | |- | ||

| colspan="8" align = center| ''Large Tube Sub-Assembly'' | | colspan="8" align = center| ''Large Tube Sub-Assembly'' | ||

| Line 624: | Line 624: | ||

|Plastic | |Plastic | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_BigTube.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 634: | Line 634: | ||

| Stainless Steel | | Stainless Steel | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_HoseClamp.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 644: | Line 644: | ||

|Rubber | |Rubber | ||

|Std. Purchase Part | |Std. Purchase Part | ||

| - | | | + | |[[Image:T9S14_Oring8.jpg]] |

|- | |- | ||

|- | |- | ||

| Line 654: | Line 654: | ||

| Stainless Steel | | Stainless Steel | ||

|Machined | |Machined | ||

| - | | | + | |[[Image:T9S14_HoseCap.jpg]] |

|- | |- | ||

Revision as of 20:22, 30 January 2014

Executive Summary

Use Study

1. What are the stakeholder needs?

- What attributes does the user need for from the product? What attributes does the retailer have?

- The User/Bartender:

- This product will be principally used by bartenders at commercial food and drink establishments. This product allows for multiple soda types to be served at a quick pace with uniform accuracy. The user expects that the product will complete the task at hand, namely separating different soda type.

- Some key qualities that the bartender expects are:

- Responsive, fast serving when each button is pressed

- Easy to understand button configuration and operating procedures allowing for operation with little training and muscle memory

- Typically, these types of devices are built in an industry-standard layout.

- Any hoses or pumps must reach the full range of bar in case other employees need it

- It may be common for multiple bartenders and/or waiters to need access as well

- Easy to repair, easy to maintain, easy to clean

- Avoiding contamination issues will allow the establishment to be healthy and satisfy customer needs (no one wants a coke with orange soda residue in it)

- The user expects durable quality

- During peak hours, the gun may be thrown around, dropped etc.

- The user would like the product to be “Ergonometricly” friendly

- Over the course of a long shift, the user may hold and operate the gun for a long time

- Most products come with a holster that allows for storing and draining when the gun is not in use. The product must fit snugly in the holder to prevent any jostling, but also accessible enough to allow for easy removal and use, ideally with one hand.

- The Restaurant/Bar Owner:

- From the perspective of the owner, this product should be cheap to manufacture, require little maintenance, and be durable enough to last a long time after purchase. In many cases, the beverage company itself is responsible for the installation and maintenance of the gun, but if the owner can avoid these costs, he would be interested.

- The Retailer:

- The retailer of the gun wants the product to be aesthetically pleasing, which encourages customers to buy the gun and use it at their bar. He also expects the gun to be of high-quality to support his business, which may include water-resistance and consistent flow-rate. The gun should be as compact as possible while performing the task at hand to allow for easier shipping, and giving bars the greatest amount of room to operate in, without bulky equipment in the way. Finally, the retailer wants the product to be easily explained and easily integrate-able into a bar. This allows for easier sales and a more diverse customer base.

2. How the product works mechanically

- - Press a button, and it opens a valve connected to a type of soda. The gun then mixes water, carbon dioxide, and the designated syrup and distributes the mixture into a cup.

- - The strength of the syrup in the mixture and what types of drinks are available are customizable and adjustable, allowing for the user to create a set up that best works for their demand and beverage company contracts.

3. How the product is used (step by step)

- (Set-Up)

- Learn which buttons go to each soda

- Pick up gun

- Point nozzle to cup

- Press appropriate button

- Fill to required level

- Re-holster gun

Bill of Materials

| Part # | Part Name | QTY | Weight (g) | Function | Material | Manufacturing | Image |

|---|---|---|---|---|---|---|---|

| Soda Gun Sub-Assembly | |||||||

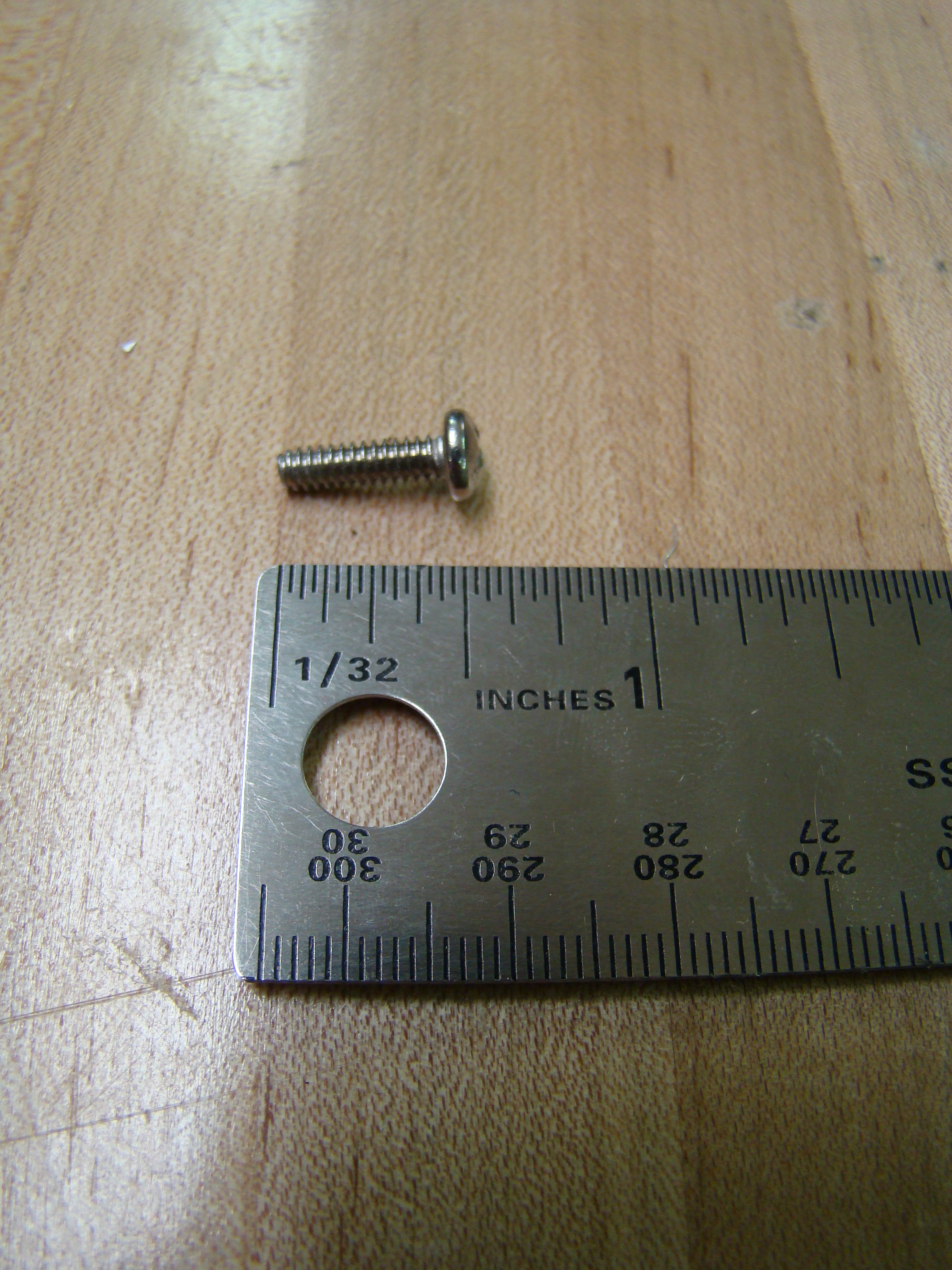

| 1 | "Round head 1/2" Length 1/8th" Dia Phillips" | 2 | <1 | Fastens button panel | Stainless Steel | Std Purchase Part |

|

| 2 | Elliptical Soda Button (Top) | 2 | <1 | User input button for soda, designates type | Plastic | Injection Molded |

|

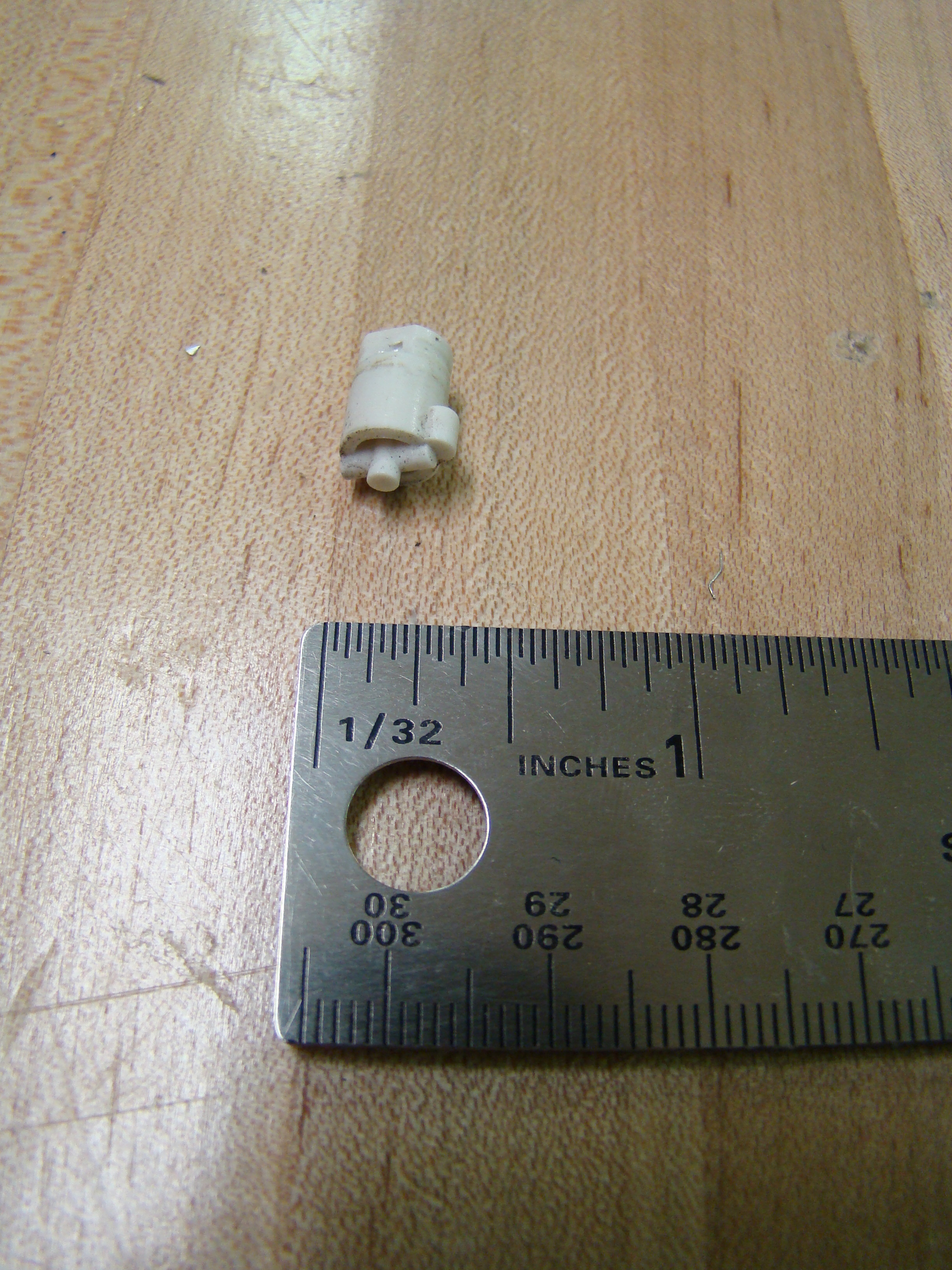

| 3 | Eliptical Soda Button (Bot) | 2 | <1 | Translates input key foce to release soda | Plastic | Injection Molded |

|

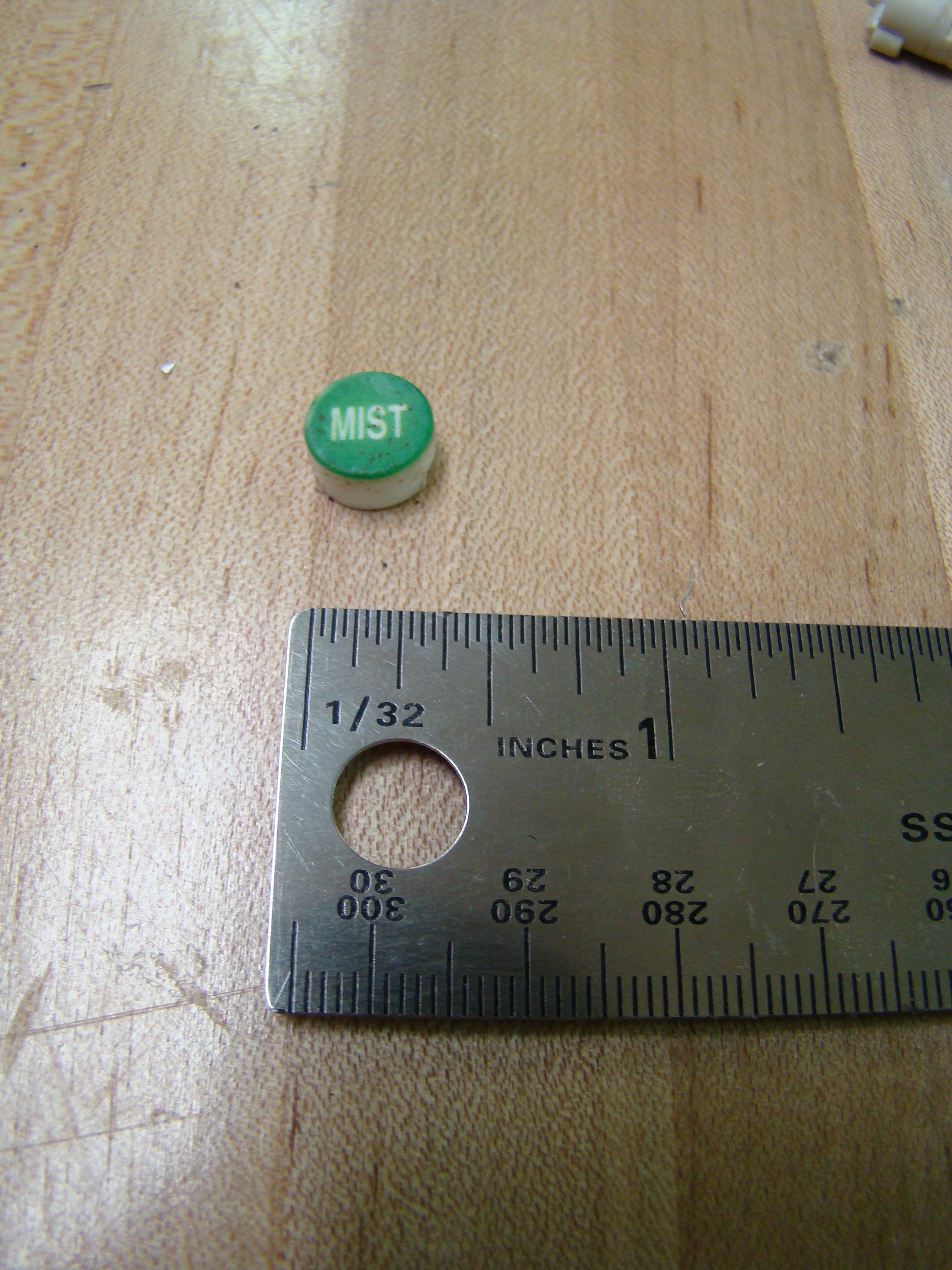

| 4 | Circle Soda Button (Top) | 8 | <1 | User input button for soda, designates type | Plastic | Injection Molded |

|

| 5 | Circle Soda Button (Bot) | 8 | <1 | Translates input key force to release soda | Plastic | Injection Molded |

|

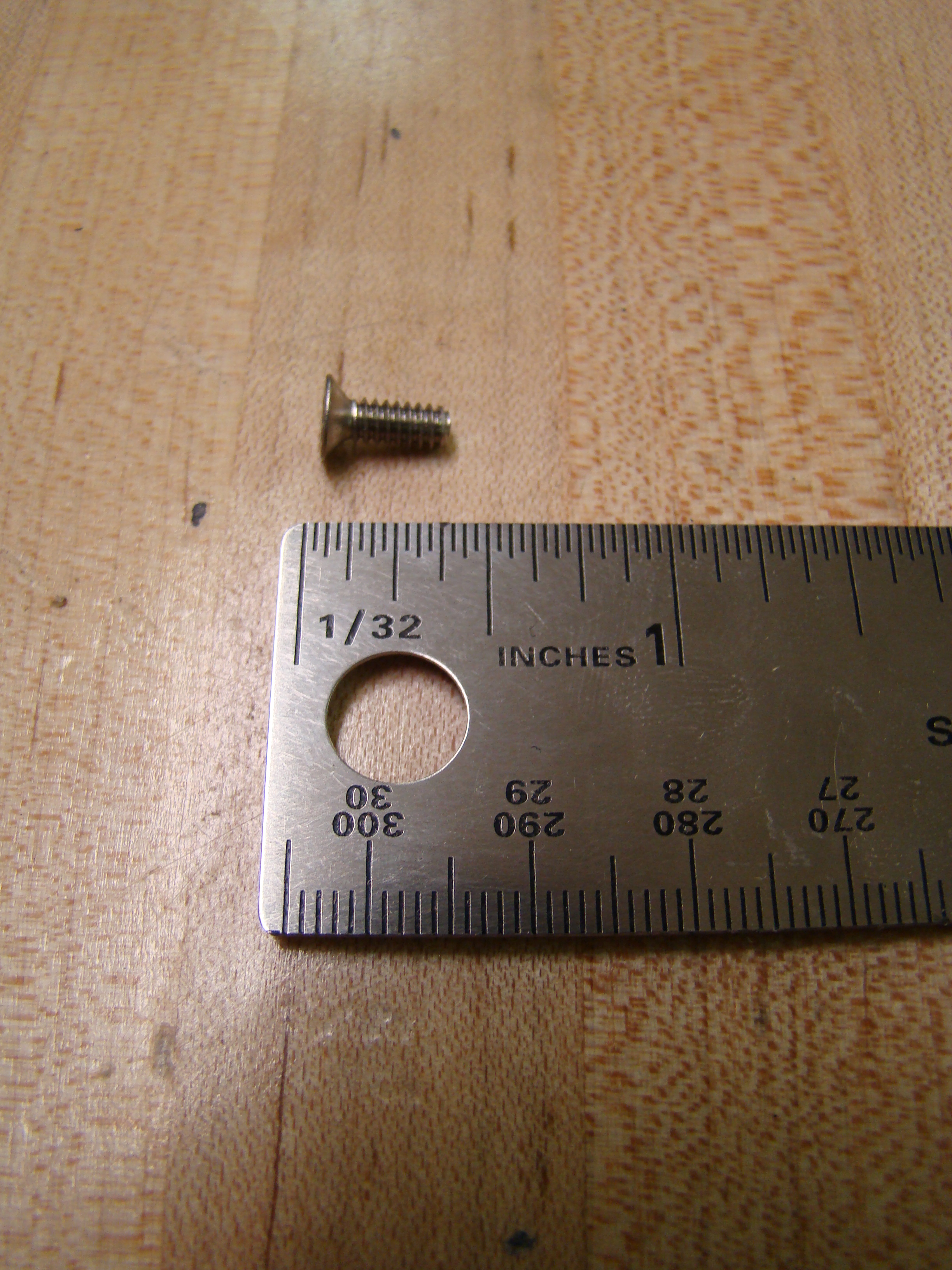

| 6 | "Flat head 3/8" len 1/8" dia philips" | 2 | <1 | Fastens panel to gun body | Stainless Steel | Std Purchase Part |

|

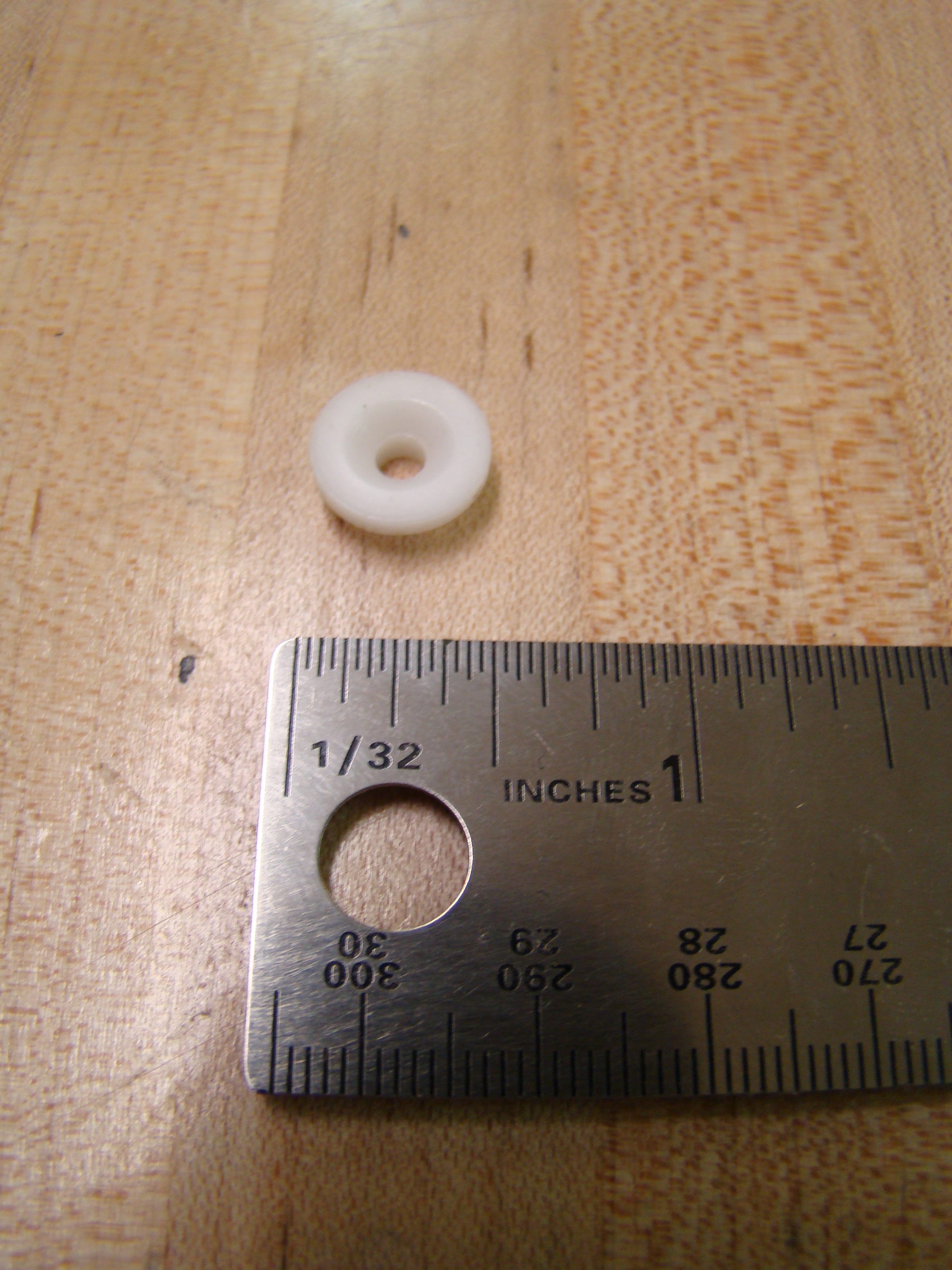

| 7 | Plastic Washer (For Part #6) | 2 | <1 | Spacing | Plastic | Injection Molded |

|

| 8 | Small Butterfly Clip | 2 | <1 | Aligns button to pin valves | Stainless Steel | Die Cast, punched | Image:T9S14 ButterflyClip.jpg |

| 9 | Large Butterfly Clip | 2 | <1 | Aligns button to pin valves | Stainless Steel | Die Cast, punched |

|

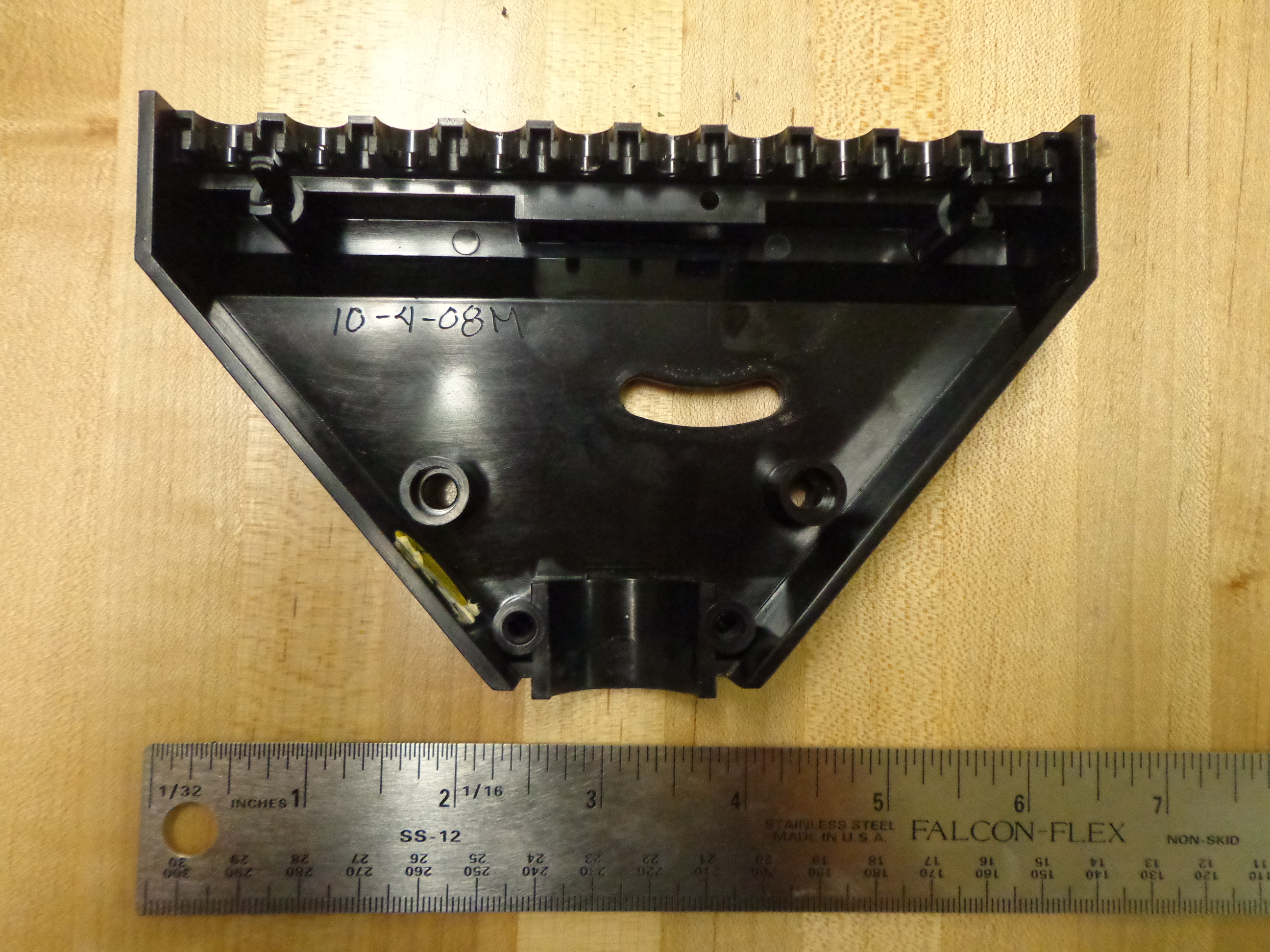

| 10 | Button Panel, blue, 10 button | 1 | 12 | Holds all buttons in place | Plastic | Injection Molded |

|

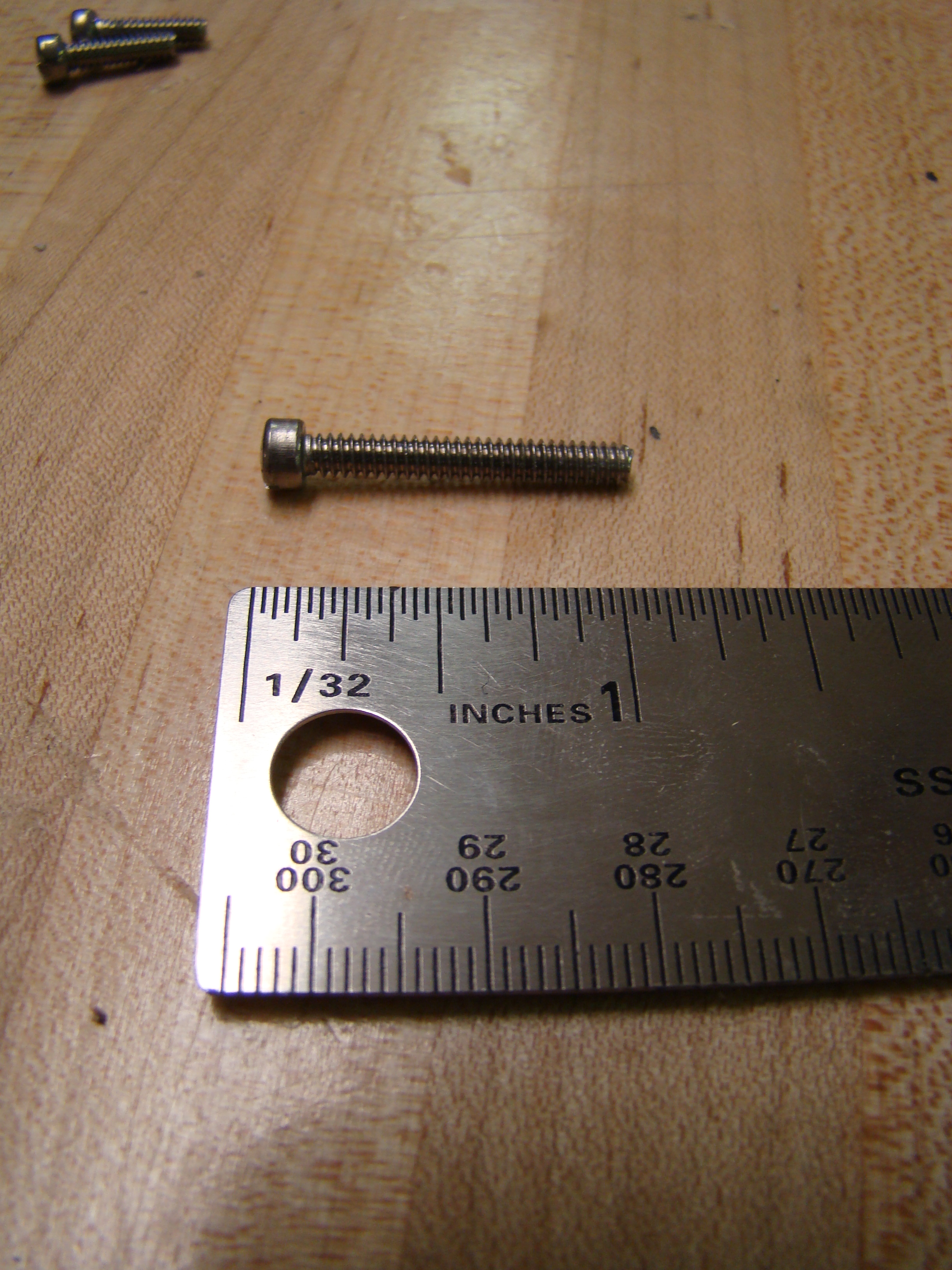

| 11 | "Round head 1" len 1/8" dia flat screw" | 2 | <1 | Fastened gun to hose base | Stainless Steel | Std Purchase Part |

|

| 12 | "Round head 1/2" len, 1/8" dia flat screw" | 2 | <1 | Fastened gun to hose base | Stainless Steel | Std Purchase Part |

|

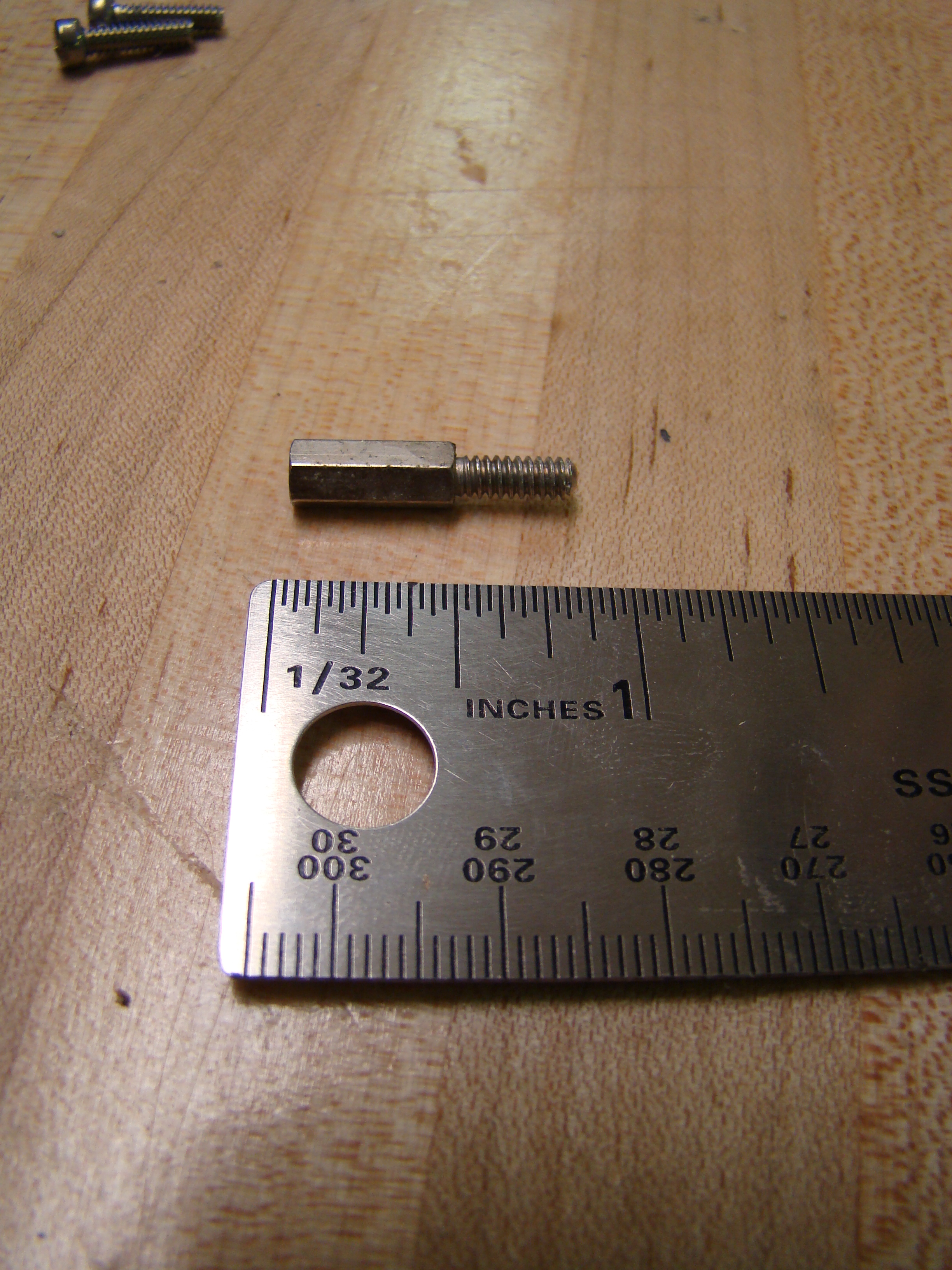

| 13 | "Hexagon, 7/8" len, 1/8" dia threaded head (Receives Part #11)" | 2 | <1 | Fastened gun to hose base | Stainless Steel | Std Purchase Part |

|

| 14 | Nozzle caps, clear plastic | 10 | <1 | Reduces hose diameter into gun base | Plastic | Injection Molded |

|

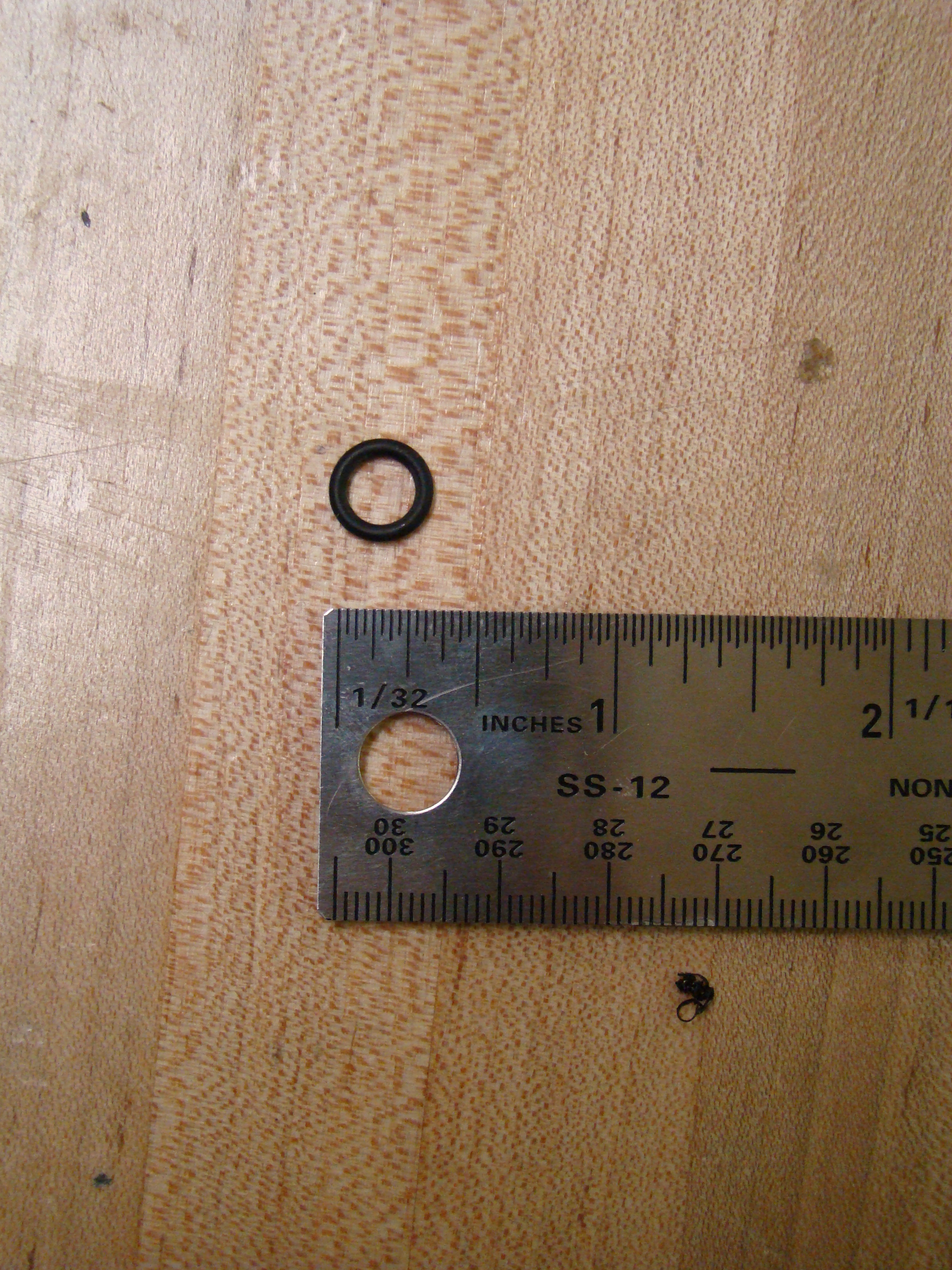

| 15 | O-ring, rubber | 10 | <1 | Seals hose to gun base | Rubber | Std Purchase Part |

|

| 16 | "Round head, 3/8" len, 1/8" dia, philips screw" | 5 | <1 | Fasten back panel to gun | Stainless Steel | Std Purchase Part |

|

| 17 | Back panel, blue | 1 | 6 | Provides grip to back of gun, aesthetic | Plastic | Injection Molded |

|

| 18 | "Custom screw, 1/2" len, 1/8" dia, flat head" | 1 | <1 | Supports back panel | Stainless Steel | Std Purchase Part |

|

| 19 | Rubber o-ring for Part #18 | 1 | <1 | Seals screw, provides snug fit | Rubber | Std Purchase Part |

|

| 20 | "O-ring, rubber, red 1/4" dia" | 12 | <1 | Seals valve assy | Rubber | Std Purchase Part |

|

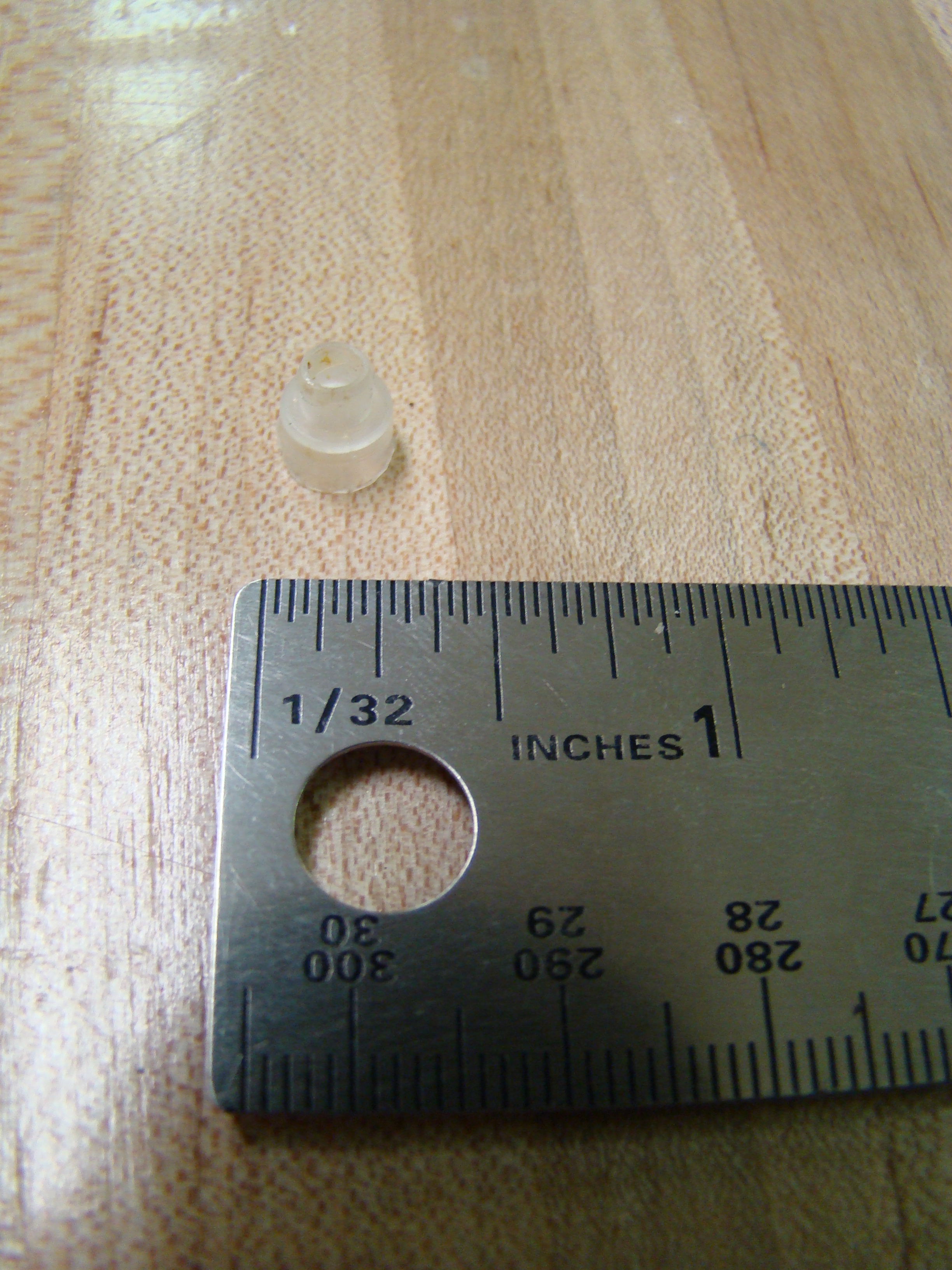

| 21 | Clear plastic spring cap | 12 | <1 | Caps spring (Part #22) | Plastic |

| |

| 22 | "Small spring, 1/2" len" | 12 | <1 | Translates input to opening valve, reset valv when released | Stainless Steel | Std Purchase Part |

|

| 23 | "O-ring, rubber, red, 1/8" dia" | 12 | <1 | Seals (Part #24) to valve assy | Rubber | Std Purchase Part |

|

| 24 | Pin | 12 | <1 | Holds valve in place, allows for vertical motion | Stainless Steel | Std Purchase Part |

|

| 25 | Plastic valve | 12 | <1 | Glued to pin, opens/closes each syrup line | Plastic | Injection Molded |

|

| 26 | Soda gun Nozzle, plastic, blue | 1 | 13 | Focuses final soda dispense | Plastic | Injection Molded |

|

| 27 | "Black, O-ring, rubber, 1" dia" | 1 | <1 | Seals nozzle head to gun | Rubber | Std Purchase Part |

|

| 28 | Soda gun body | 1 | 113 | Directs and organizes flow for all fluids exiting soda gun | Plastic | Machined in five layers, irreversibly sealed together, post-drilled |

|

| 29 | Soda gun nozzle base | 1 | 10 | Creates central location for syrup+soda to mix and exit gun | Plastic | Turned, glued to soda gun body |

|

| 30 | Soda gun nozzle base retaining pins | 2 | <1 | Create fixture points for nozzle base | Stainless Steel | Turned |

|

| 31 | Stickers (misc.) | 12 | <1 | Provides information and instructions about product, barcodes, safety information use, and beverage types | Paper | Printed |

|

| Flow Regulator Sub-Assembly | |||||||

| 32 | Plastic Regulator Backing | 1 | 41 | Hold tubes to regulator | Plastic | Injection Molded |

|

| 33 | "flat top, 1" len, 1/4" dia, philips head screw" | 4 | 3 (ea) | Fastens regulator casing together | Stainless Steel | Std Purchase Part |

|

| 34 | Tube retainer, retaining clips | 20 | <1 | Retain the tube retainers to base | Stainless Steel | Std Purchase Part |

|

| 35 | Tube housing, main body | 1 | 46 | Holds the tube housing | Plastic | Injection Molded |

|

| 36 | Tube housing, single holder | 10 | 6 | Connects two sides of tubes | Plastic | Injection Molded |

|

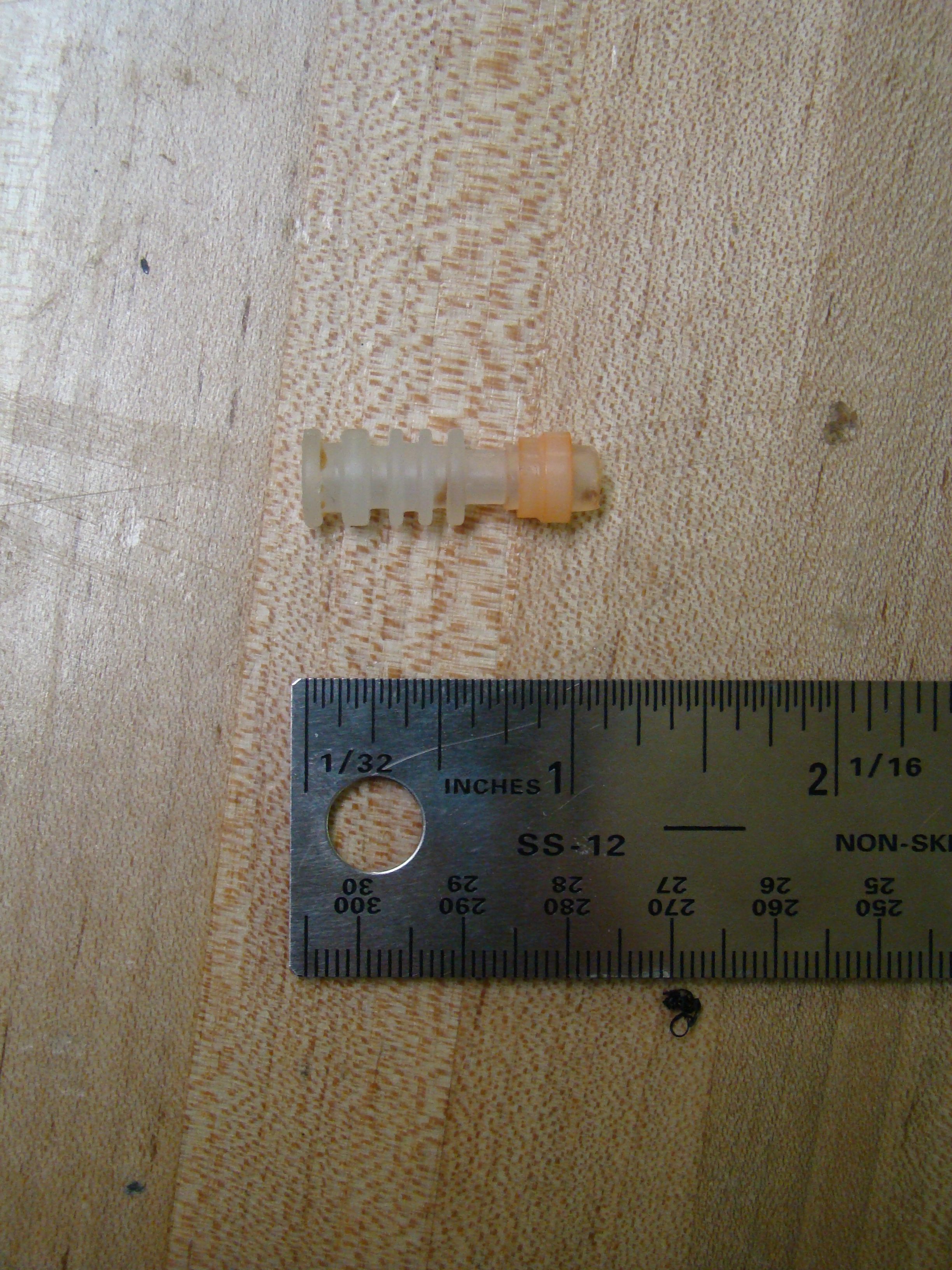

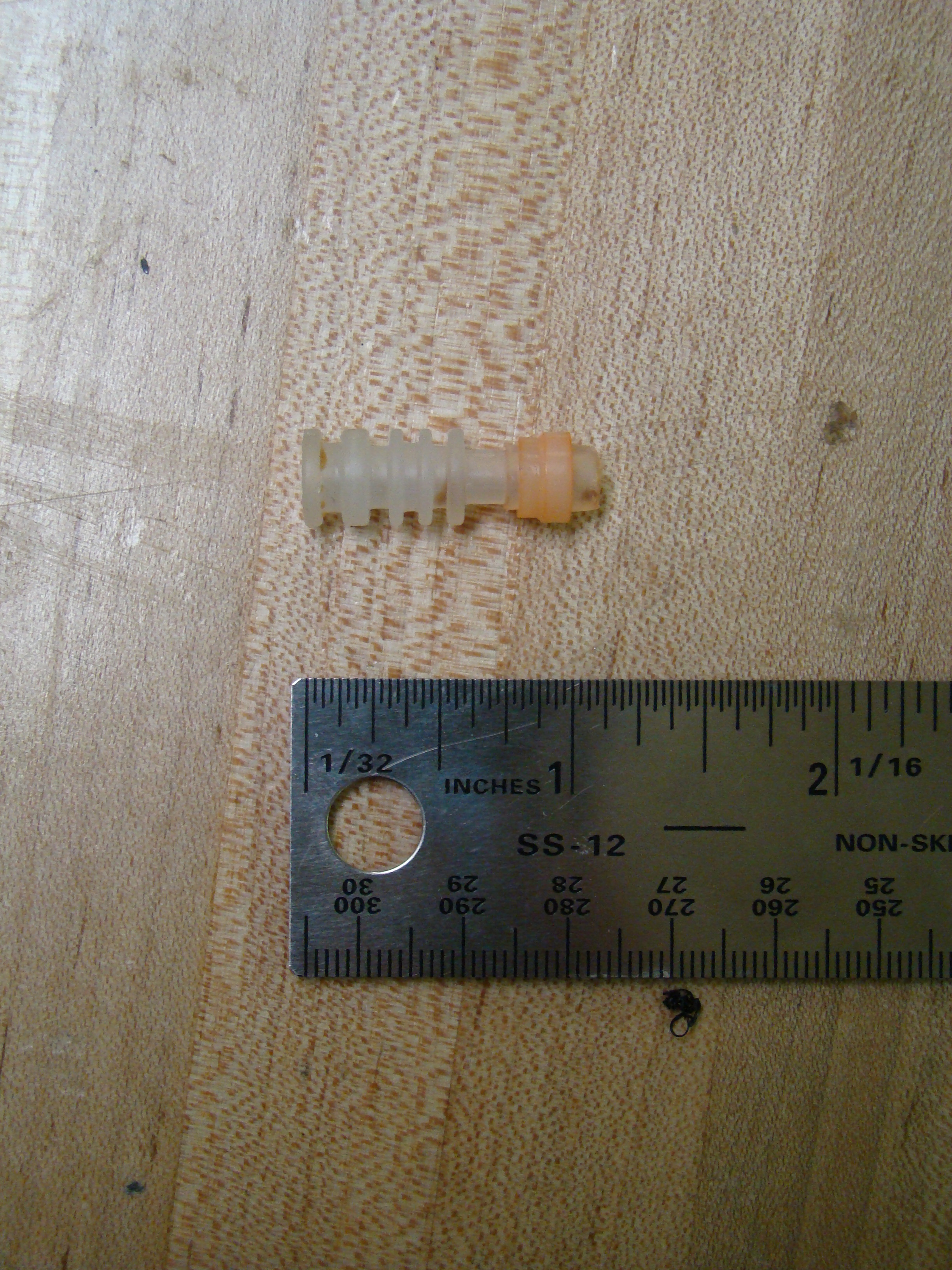

| 37 | Shut-off screw | 10 | <1 | Shuts off soda flow | Plastic | Injection Molded |

|

| 38 | "Shut-off screw o-ring 1/4" dia, rubber" | 10 | <1 | Seals shut-off screws | Rubber | Std. Purchase Part |

|

| 39 | Flow adjustment screw | 10 | <1 | Adjusts syrup/water ratio | Plastic | Injection Molded |

|

| 40 | "Flow adjustment screw o-ring, 1/4" dia, rubber" | 10 | <1 | Seals adjustment screw | Rubber | Std. Purchase Part |

|

| 41 | "Housing retaining pin 1", 5/32" dia" | 2 | 4 | Holds tube housing halves together | Stainless Steel | Cut to length |

|

| 42 | Pivot pin for separating mechanism | 1 | <1 | Creates pivot point for half separator of plastic reg. housing | Stainless Steel | Cut to length |

|

| 43 | Plastic regulator fronting | 1 | 63 | Hold tubes to regulator | Plastic | Injection Molded |

|

| 44 | Cap of separating mechanism, white | 1 | <1 | User interaction point for separator mechanism | Plastic | Injection Molded |

|

| 45 | Cap of separating mechanism pivot | 1 | <1 | Held cap to main separating body | Stainless Steel | Turned/Lathed |

|

| 46 | Main separator body | 1 | 5 | Separates the halves | Plastic | Injection Molded |

|

| Small Tube Sub-Assembly | |||||||

| 47 | Small Eaton Synflex Tubing (4203-0400) | 10 | 11 | Carries syrup to gun | Plastic | Std. Purchase Part |

|

| 48 | Plastic Hose Clamping Ring | 10 | <1 | Connects syrup tubing to end cap | Plastic | Injection Molded |

|

| 49 | Ridged End-Cap | 10 | <1 | Connects tubing to dispensing system | Plastic | Injection Molded |

|

| 50 | "O-ring, rubber, 3/8" dia, black" | 10 | <1 | Seals end cap | Rubber | Std. Purchase Part |

|

| 51 | Plastic, anti-friction ring | 1 | 1 | Prevents metal casing from cutting tubing | Plastic | Injection Molded |

|

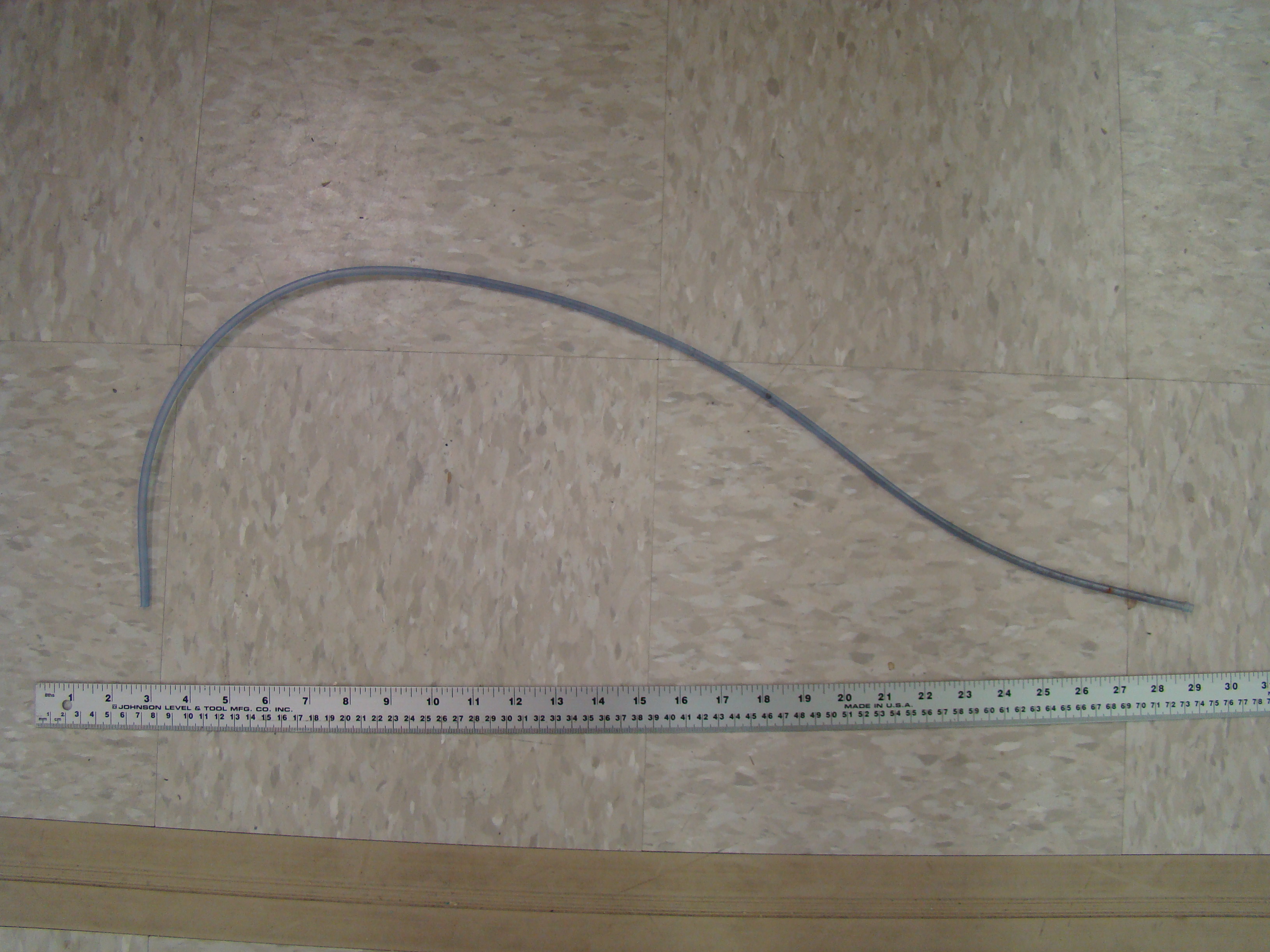

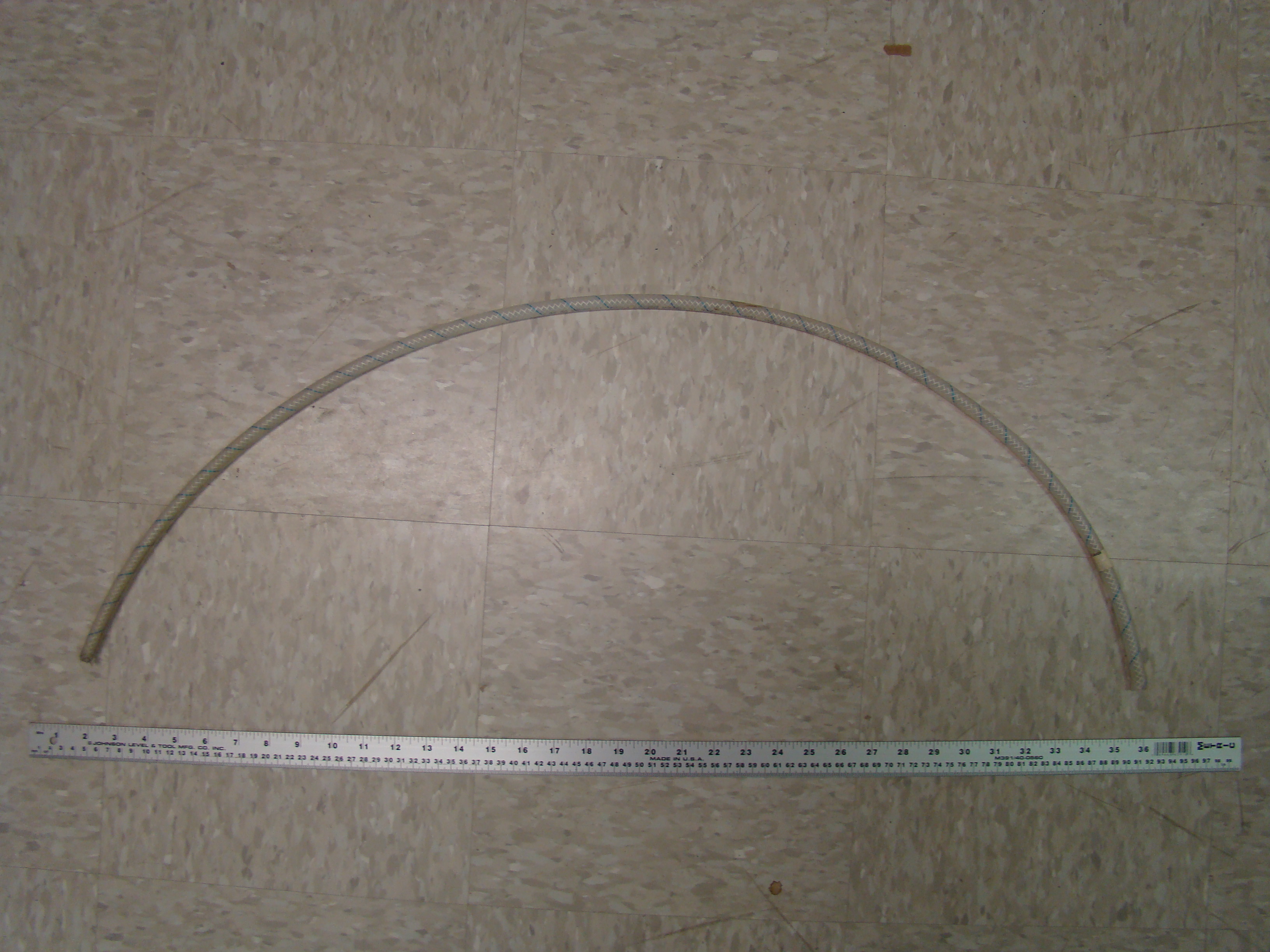

| 52 | Outer tubing casing, metal | 1 | 200 | Gathers all tubes, protects against wear, allows for flexible movement | Stainless Steel | Std. Purchase Part |

|

| 53 | Soda gun base connector | 1 | 11 | Connects handheld gun to the tubing casing | Plastic | Injection Molded |

|

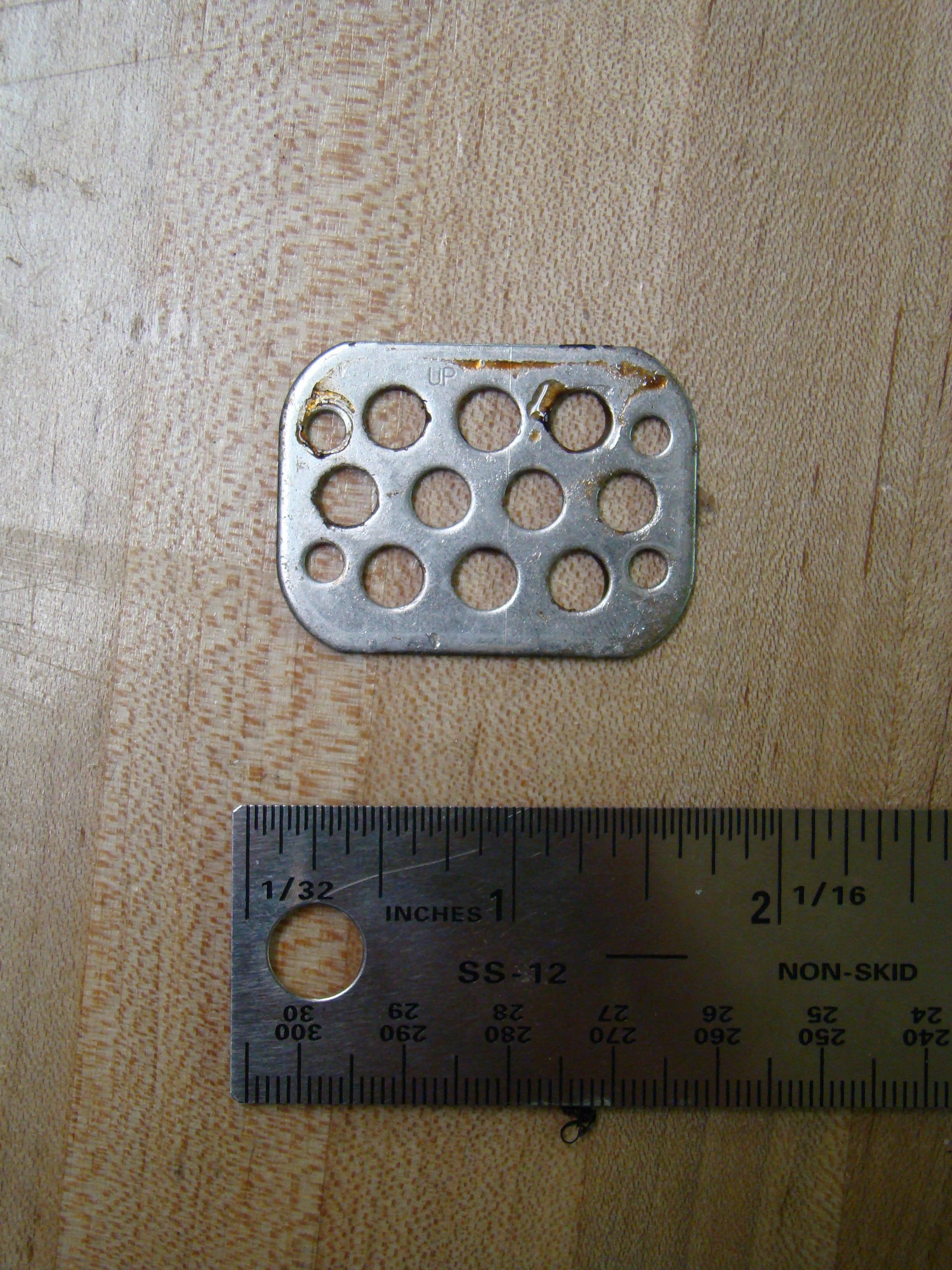

| 54 | Tubing holding plate | 1 | 10 | Holds all tubes in correct positions for handheld gun | Stainless Steel | Cut, stamped |

|

| Large Tube Sub-Assembly | |||||||

| 55 | Rev-Flex P-E Hose | 10 | 63 | Carries liquid from source to soda gun assembly | Plastic | Std. Purchase Part |

|

| 56 | Hose clamp | 10 | 2 | Fastens metal hose cap to hose | Stainless Steel | Std. Purchase Part |

|

| 57 | O-ring, rubber, black | 10 | <1 | Seals threaded hose cap to assembly | Rubber | Std. Purchase Part |

|

| 58 | Hose cap, metal | 10 | 7 | Allows liquid to flow from one tubing to another | Stainless Steel | Machined |

|