Apple peeler

From DDL Wiki

Contents |

Executive Summary

Customer Needs

The primary customer need in an Apple Peeler is to have the ability to easily and quickly remove the skin of an apple. It is also expected that the device can peel the skin off various types of fruits and vegetables of similar shape and size. Since this is an everyday kitchen ware, the first and foremost requirement for this product is ease of use and safety. If must be easy enough so that the device can be operated from common sense without instruction by people of different age groups. It must be safe to be used by small children and elders, both male and female. Customers should not have to worry about possible safety hazards caused by everyday equipment.

Stakeholders

Consumers

- The consumers are the primary stakeholders of the product. The “consumer” maybe anyone from any age group of any gender since it is an everyday kitchen ware.

- Product must be relatively cheap to purchase since the function of the product is limited as opposed to a table knife.

- Safety must be considered in detail to prevent any type of injuries.

- Design will need to accommodate various users with different sizes and strength.

- Operation of the product must be intuitive to be carried out without instruction.

- Product must efficiently and quickly skin the apple.

- Product must be able to skin apples of all sizes and shapes.

Retailers

- Retailers are concerned with how the product presents itself at their stores.

- Product must be compact as possible for efficient storage.

- Product must be of manageable weight to be handled easily at stores.

- Product must be durable enough to stay intact even when handled poorly or dropped.

- Product should be aesthetically pleasing or should be able to be made aesthetically pleasing to attract customers.

Manufacturers

- Manufacturers are concerned with ease manufacturing.

- Product should have low part count.

- Parts used should be easily accessible. This may mean that the parts have already been manufactured for other products.

- Material used in manufacturing the parts should be cheap and easily accessible.

- Assembly process should be simple, quick and easy to reduce production speed and labor costs.

Shipping/Transport

- The primary concern in shipping is to deliver product received by manufacturer to retailers in a timely manner without any variation in product quality.

- Product must be easy to handle. This may be done by reducing weight and choosing appropriate shape of the product so that when the product is boxed it is easy to handle.

- Product must be durable so that any external load applied during shipping does not affect the quality of the product.

System Function

Usability

Product Assembly

Product Dissection

Design for Manufaturing and Assembly

DFMA is a set of guidelines that allows engineers and designer to reduce the complexity and cost of manufacture of a product.

| Part Number | Item & Function | Failure Mode | Effects of Failure | S | Causes of Failure | O | Design Controls | D | RPN | Recommended Actions | Responsibility & Deadline | Actions Taken | S | O | D | RPN |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 3 | Corer/slicer blade | Blunt, bending | Operation impaired | 7 | Extended use | 7 | Durability test | 1 | 49 | Better material | Materials Engineer | - | - | - | - | - |

| 5 | U-shape peeler | Blunt | Operation impaired | 7 | Extended use | 7 | Durability test | 1 | 49 | Better material | Materials Engineer | - | - | - | - | - |

| 8 | Peeler handle stopper | Deformed | Not able to disable peeler | 5 | Fatigue | 4 | Durability test | 2 | 40 | Reinforcement, thicker metal | Mechanical Engineer | - | - | - | - | - |

| 11 | Coil (peeler handle) | Loosened | Not able to peel | 8 | Extended use | 4 | Lifetime test | 6 | 192 | Alternative solutions | Mechanical Engineer | - | - | - | - | - |

| 12 | Peeler handle | Deformed | Operation impaired | 7 | Fatigue | 2 | Lifetime test | 2 | 28 | Reinforcement | Mechanical Engineer | - | - | - | - | - |

| 13 | Grooved channel | Cracked groove | Rough operation | 7 | Wear | 3 | Fleet test | 3 | 63 | Better material | Materials Engineer | - | - | - | - | - |

| 14 | Tri-fork | Deformed, loosened | Unstable operation | 6 | Excessive force from user, fatigue | 5 | Fleet test | 4 | 120 | Redesign structure | Mechanical Engineer | - | - | - | - | - |

| 16 | Wooden handle | Cracked | Rough operation, might injure user | 5 | Wear, corrosion | 5 | Lifetime test | 3 | 75 | Better material | Materials Engineer | - | - | - | - | - |

| 17 | Handle lever | Deformed | Erratic operation | 2 | Fatigue | 2 | Durability test | 3 | 12 | Reinforcement | Mechanical Engineer | - | - | - | - | - |

| 18 | Plastic ring | Cracked | Unstable operation | 4 | Wear | 3 | Durability test | 7 | 84 | Better material | Materials Engineer | - | - | - | - | - |

| 19 | Channel stopper | Deformed | Operation impaired | 7 | Wear, fatigue | 4 | Lifetime test | 5 | 140 | Reinforcement, thicker metal | Mechanical Engineer, Materials Engineer | - | - | - | - | - |

| 20 | Coil (channel stopper) | Loosened | Operation impaired | 7 | Wear | 4 | Lifetime test | 6 | 168 | Alternative solutions | Mechanical Engineer | - | - | - | - | - |

| 21 | Channel stopper rivet | Cracked, loosened | Unstable operation | 5 | Wear, fatigue | 2 | Fleet test | 7 | 70 | Alternative solutions | Mechanical Engineer | - | - | - | - | - |

| 22 - 26 | Vacuum | Failure | Vacuum inoperative | 7 | Wear | 6 | Fleet test | 4 | 168 | Better design | Mechanical Engineer | - | - | - | - | - |

| 27 | Base case | Deformed | Poor appearance | 3 | Fatigue | 3 | Durability test | 2 | 18 | Reinforcement | Mechanical Engineer | - | - | - | - | - |

| 30 | Main body | Deformed | Unstable operation | 4 | Fatigue | 2 | Durability test | 2 | 16 | Reinforcement | Mechanical Engineer | - | - | - | - | - |

| 1, 2, 4, 6, 7, 9, 10, 15, 28, 29 | Butterfly nuts, washers, screws | Loosened, threads stripped | Rough, unstable | 3 | Wear | 4 | Lifetime test | 7 | 84 | Better material, alternative solutions | Materials Engineer, Materials Engineer | - | - | - | - | - |

Apple Peeler DFM

The apple peeler exhibits good DFMA, it is simple and functional with few parts. When examining and dissecting our products, we divided the product into 6 major components: the corer/slicer, the peeler, the grooved channel, the main body, the base, and the vacuum sticker. First of all, the corer/slicer is made of stainless steel and is made through stamping stock into the desired shape. The design of the corer/slicer is developed so that the appropriate size of the core can be extruded while the apple goes through. The u-shaped peeler is also made of stainless steel and is made by stamping. The peeler handle is connected to a spring so that it can adjust the peeler into the best position with appropriate force exerting on the apple. Moreover, the grooved channel is made of stainless steel and is made by extrusion. The tri-fork that holds the apple is connected to the very front of the grooved channel. As we spin the handle, the tri-fork would gradually rotate and move toward the blade. The main body and the base are both made of steel and are made by molding. The last component is the vacuum sticker. The vacuum sticker is made of rubber and is made by injection molding. One thing should be pointed out here is that the vacuum rubber case contains a hard rubber plate with 9 equally space holes. They did surface treating on the rubber case so that the surface is smooth, the apple peeler can thus effectively stay firmly. Furthermore, the peeler handle, the main body, and the base would be painted. Since these three parts are made of steel, painting is a necessary operation to prevent steel from rusting.

Apple Peeler DFA

The way the apple peeler is assembled is by pre-manufactured fasteners, which increases the ease of assembly. The fasteners used in this design, however, have different thread size on different parts, which would increase the difficulty of assembly. The apple peeler actually includes 30 components. Even though we only mentioned about five main parts here, the actual manufacturing process is indeed long and time consuming due to the large numbers of components assembly. For the future design, reducing the trivial components would definitely be one of our goals.

DFE

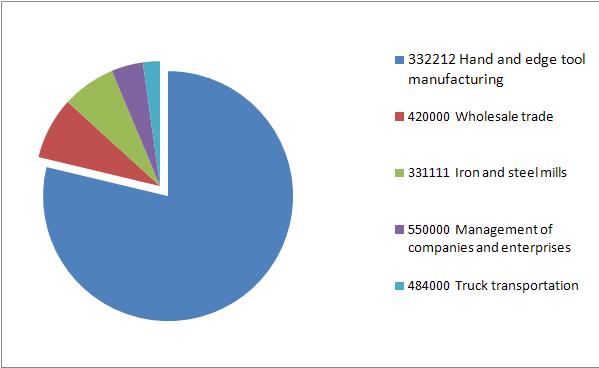

The data shows every additional $1 million dollar stimulate a total of $2.43 million in all sectors combined (net implied economic activity).

Wholesale Trade gains 0.131 million, and Iron & Steel Mills gains 0.085 million economic flux. Considering apple peeler is a low tech product,

it is most made of metal or steel, so Iron & Steel Mills comes third. More investments are going into distributing and resell the product.