Ceiling-mounted storage lift

From DDL Wiki

(→DFS) |

|||

| Line 23: | Line 23: | ||

Safety was a primary consideration in the design of the ceiling-mounted storage lift. We took the time to analyze and verify the design of each component so that the failure mode of the product in extreme conditions is one that will not cause major damage or injury. Similar to the ceiling-mounted bicycle lift, the primary mode of failure in an overloaded condition is slippage of the rope through the locking mechanism. We performed tests on the ceiling-mounted bicycle lift to determine the maximum loading that would cause failure. We gradually increased the weight of the object hung from the lift and applied a dynamic load to see if the lift would fail. The results of our testing showed that the lift failed when a dynamic load was applied to an object with a weight of 240 pounds. A video of the testing can be seen at the following link: http://www.youtube.com/watch?v=2OQ_4o4JSPw . | Safety was a primary consideration in the design of the ceiling-mounted storage lift. We took the time to analyze and verify the design of each component so that the failure mode of the product in extreme conditions is one that will not cause major damage or injury. Similar to the ceiling-mounted bicycle lift, the primary mode of failure in an overloaded condition is slippage of the rope through the locking mechanism. We performed tests on the ceiling-mounted bicycle lift to determine the maximum loading that would cause failure. We gradually increased the weight of the object hung from the lift and applied a dynamic load to see if the lift would fail. The results of our testing showed that the lift failed when a dynamic load was applied to an object with a weight of 240 pounds. A video of the testing can be seen at the following link: http://www.youtube.com/watch?v=2OQ_4o4JSPw . | ||

| - | Since the pulley system in the ceiling-mounted bicycle lift has a mechanical advantage of four to one, the tension in the rope is 60 pounds for a maximum load of 240 pounds. In our design, a tension of 60 pounds in each rope corresponds to a load of 480 pounds. To insure that the primary mode of failure in our design is slippage in the rope, we analyzed and verified that the structural components of concern in our design are capable of withstanding a load of 600 pounds. The components we analyzed were the wheel axles and the pulley brackets. The analyses are shown in detail on our [[Ceiling-mounted storage lift numerical analysis]] page. From our axle sizing table, we were able to select the appropriate axle diameter once we determined the separation distance between the wheel and the side of the pulley bracket. To minimize torsion on the L-channel track, we decided to place the wheels as close as possible to the vertical wall of the track. This makes the separation distance 1.25 inches | + | Since the pulley system in the ceiling-mounted bicycle lift has a mechanical advantage of four to one, the tension in the rope is 60 pounds for a maximum load of 240 pounds. In our design, a tension of 60 pounds in each rope corresponds to a load of 480 pounds. To insure that the primary mode of failure in our design is slippage in the rope, we analyzed and verified that the structural components of concern in our design are capable of withstanding a load of 600 pounds. The components we analyzed were the wheel axles and the pulley brackets. The analyses are shown in detail on our [[Ceiling-mounted storage lift numerical analysis]] page. From our axle sizing table, we were able to select the appropriate axle diameter once we determined the separation distance between the wheel and the side of the pulley bracket. To minimize torsion on the L-channel track, we decided to place the wheels as close as possible to the vertical wall of the track. This makes the separation distance 1.25 inches. We sized our axles for steel with a yield strength of 40,000 psi and chose a diameter of 5/16 inches. We also performed a finite element analysis using ANSYS to verify the structural integrity of the pulley brackets. We performed the analysis on simplified shapes and concluded that our pulley brackets would not fail under the same load. |

===FMEA=== | ===FMEA=== | ||

Revision as of 16:10, 5 May 2007

This article was contributed as part of a design project for the course 24-441 Engineering Design in the spring semester of 2007 at Carnegie Mellon University.

Team 1 - Report 1: Ceiling-mounted bicycle lift

Team 1 - Report 2: Ceiling-mounted bicycle lift redesign

Contents |

Executive Summary

Project Background

Opportunity & Market Research

Product Description

Components

Our Ceiling-mounted storage lift BOM contains the quantity of each component in our product, the weight of that component, its function, the material it's made of and its most likely manufacturing process. It also contains both a CAD image and a dimensioned drawing of each custom part and a catalog reference for each purchased part. ---little extra summary about BOM---

Assembly

Engineering Analysis

DFMA

DFU

DFS

Safety was a primary consideration in the design of the ceiling-mounted storage lift. We took the time to analyze and verify the design of each component so that the failure mode of the product in extreme conditions is one that will not cause major damage or injury. Similar to the ceiling-mounted bicycle lift, the primary mode of failure in an overloaded condition is slippage of the rope through the locking mechanism. We performed tests on the ceiling-mounted bicycle lift to determine the maximum loading that would cause failure. We gradually increased the weight of the object hung from the lift and applied a dynamic load to see if the lift would fail. The results of our testing showed that the lift failed when a dynamic load was applied to an object with a weight of 240 pounds. A video of the testing can be seen at the following link: http://www.youtube.com/watch?v=2OQ_4o4JSPw .

Since the pulley system in the ceiling-mounted bicycle lift has a mechanical advantage of four to one, the tension in the rope is 60 pounds for a maximum load of 240 pounds. In our design, a tension of 60 pounds in each rope corresponds to a load of 480 pounds. To insure that the primary mode of failure in our design is slippage in the rope, we analyzed and verified that the structural components of concern in our design are capable of withstanding a load of 600 pounds. The components we analyzed were the wheel axles and the pulley brackets. The analyses are shown in detail on our Ceiling-mounted storage lift numerical analysis page. From our axle sizing table, we were able to select the appropriate axle diameter once we determined the separation distance between the wheel and the side of the pulley bracket. To minimize torsion on the L-channel track, we decided to place the wheels as close as possible to the vertical wall of the track. This makes the separation distance 1.25 inches. We sized our axles for steel with a yield strength of 40,000 psi and chose a diameter of 5/16 inches. We also performed a finite element analysis using ANSYS to verify the structural integrity of the pulley brackets. We performed the analysis on simplified shapes and concluded that our pulley brackets would not fail under the same load.

FMEA

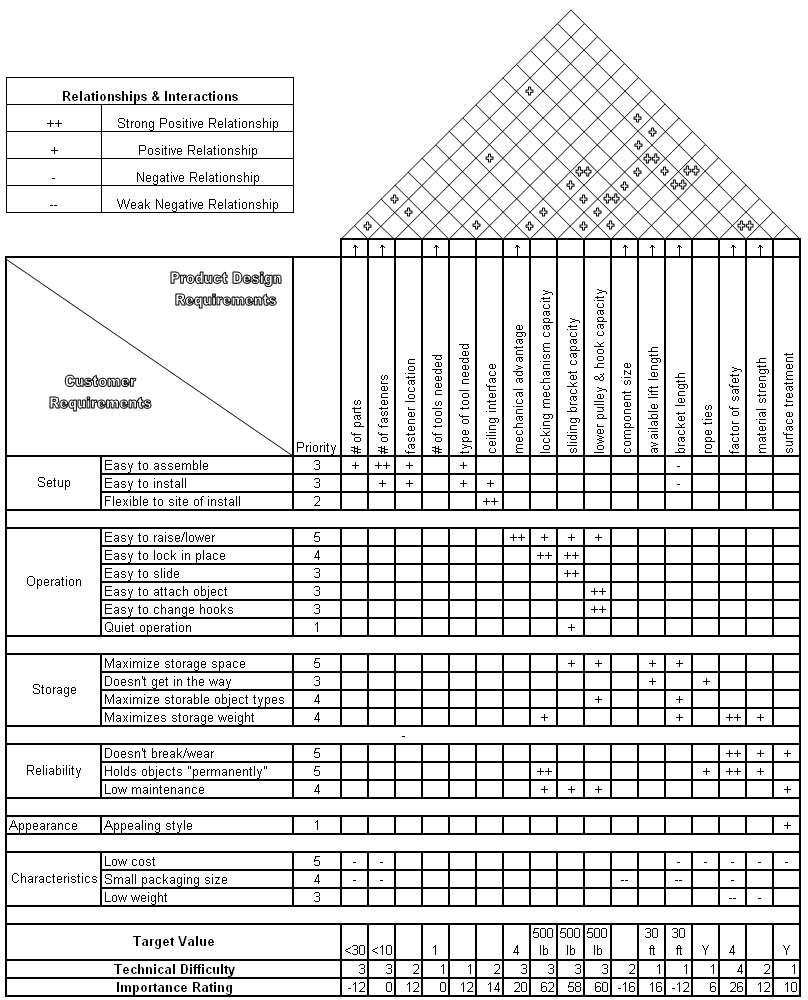

Quality Function Deployment

Conclusion

Final Prototype

User-testing

Conclusion

Production Plan

Group Members: Jeff Polack, Kevin Pruzinsky, Davey Quinn, Russel Verbofsky