Umbrella check-out system

From DDL Wiki

(→QFD) |

(→Market Analysis) |

||

| Line 6: | Line 6: | ||

===Market Analysis=== | ===Market Analysis=== | ||

| - | |||

To identify major customer needs regarding the umbrella usage, market analysis and user studies related to the product were conducted by getting feedback of the actual users for different types of umbrellas. Based on the observations and answers to the survey questions, out team has identified four major customer needs: | To identify major customer needs regarding the umbrella usage, market analysis and user studies related to the product were conducted by getting feedback of the actual users for different types of umbrellas. Based on the observations and answers to the survey questions, out team has identified four major customer needs: | ||

Revision as of 23:07, 5 December 2008

Contents |

Executive Summary

Design

Objectives and Opportunities

Why we believe that this is a feasible idea, user study quotes

Market Analysis

To identify major customer needs regarding the umbrella usage, market analysis and user studies related to the product were conducted by getting feedback of the actual users for different types of umbrellas. Based on the observations and answers to the survey questions, out team has identified four major customer needs:

- Umbrellas should be hard to lose

- Umbrellas should be easy to open and close

- Umbrellas need to be portable

- Umbrellas should provide adequate coverage

Pictures

This picture shows how users often rest umbrellas on their shoulders instead of holding them vertical.

This picture shows how users often carry umbrellas at their center of gravity because it makes it more comfortable to hold.

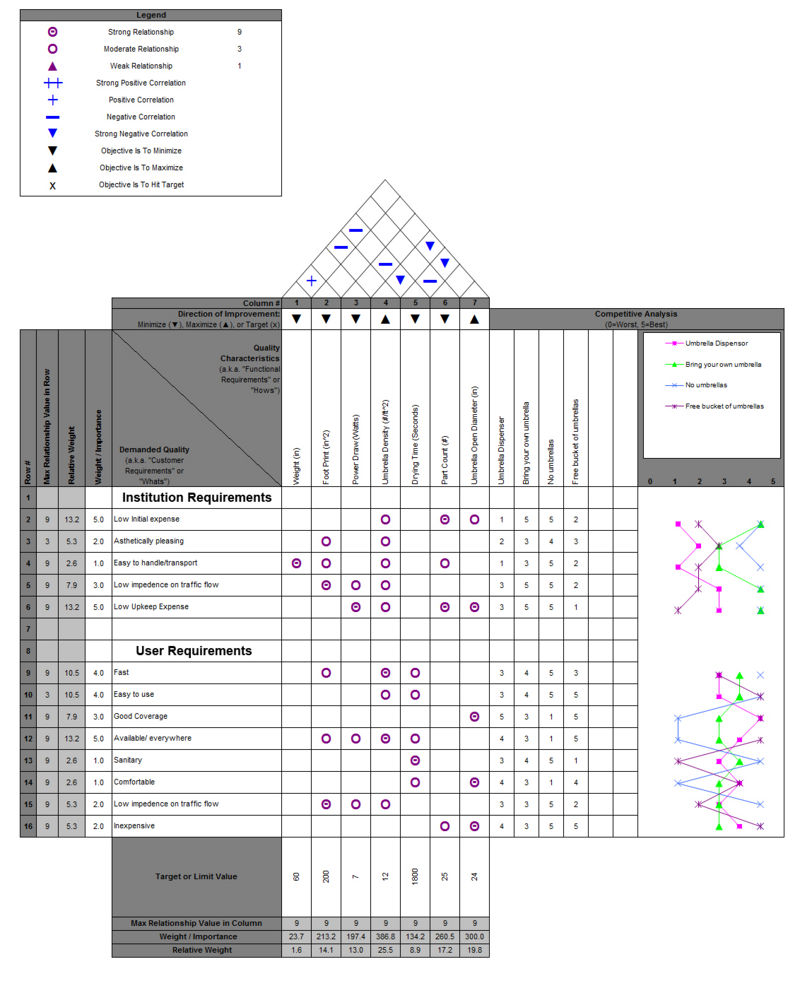

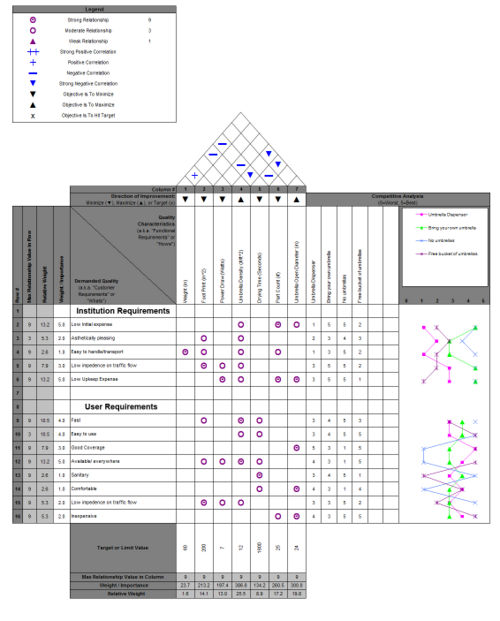

QFD

Concept Design

Overview and Usage

This concept is a system of umbrella distribution units. Each unit is small and battery powered.

Users swipe an ID card at the lower end of the unit. This dispenses one umbrella through the turnstile. The umbrella's ID number is logged in the user's account information. The user then walks to their next location, depositing the umbrella into a unit at the new location. A reader at the new location notes the umbrella coming in, and removes that umbrella from the user's account.

The system will know when a user has checked out an umbrella and not returned it. Users can be charged a penalty if umbrellas are not returned with a given timeframe.

Physical Design

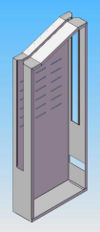

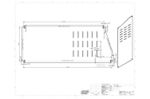

Each unit consists of four major components: the shell, the electronics subsystem, the output turnstile, and the input gate.

The shell is what encompasses all of the internals. It provides physical support for everything else.

The electronics subsystem is the heart of the unit. It consists of a microcontroller, a card scanner, and an RFID reader. The microcontroller provides the logic to control the other systems. The card scanner allows the system to identify users, and the RFID reader allows the system to identify umbrellas.

The output turnstile is what dispenses umbrellas to the user. It is a small motor attached to a worm drive gearbox. On the output shaft of the worm drive are four turnstile arms. An infrared break-beam sensor provides feedback about the turnstile's position.

The input gate is a one-way gate, allowing umbrellas to be returned to the system. A limit switch provides a signal when the gate is closed.

Table 1: Bill of Materials

| Part Number | Name | Qty. | Function | Material | Manufacturing Process | Image | Engineering Drawing | Vendor Info |

|---|---|---|---|---|---|---|---|---|

| 1 | Dispenser Shell | 1 | Encloses unit | 18 Gauge Low Carbon Steel | Cold Rolling, Punching, Bending, Welding |

|

| Not Applicable |

| 2 | Short Support | 2 | Maintains rigidity of unit | Low Carbon Steel | Cold Rolling, Drilling |

|

| Not Applicable |

| 3 | Long Support | 2 | Maintains rigidity of unit | Low Carbon Steel | Cold Rolling, Drilling |

|

| Not Applicable |

| 4 | Drip Tray | 1 | Contains moisture from wet umbrellas | 18 Gauge Low Carbon Steel | Cold Rolling Punching, Bending, Welding |

|

| Not Applicable |

| 5 | 6-32 x 3/16 Undercut Flat Head Machine Screw | 2 | Secures Drip Tray to Dispenser Shell | 18-8 Stainless Steel | Thread Rolling |

|

|

|

| 6 | Access Panel | 1 | Encloses unit, allows access for Maintainence | 18 Gauge Low Carbon Steel | Cold Rolling, Punching, Bending |

|

| Not Applicable |

| 7 | 1/4-20 x 3/8 Undercut Flat Head Machine Screw | 4 | Secures Access Panel to Dispenser Shell | 18-8 Stainless Steel | Thread Rolling |

|

|

|

| 8 | Turnstile | 1 | Regulates Umbrella Dispensing | Low Carbon Steel | Cold Rolling, Stamping |

|

| Not Applicable |

| 8 | Gear Box Assembly | 1 | Rotates Turnstile to dispense umbrellas | Misc. | Misc |

| Not Applicable |

|

| 1 | Part 1 | 1 | does stuff | Steel | Stamping | Image:Imagename.jpg | Image:Imagename.jpg | Image:Imagename.jpg |

Distribution and Placement

Units should be placed at major doorways around the institution. While it is difficult to quantify what exactly a major doorway is, it should be fairly self-evident to people that frequent the facility.

The umbrella dispenser's small footprint allows it to be placed almost anywhere in a hallway. Even a short row of dispensers does not occupy much floorspace. Dispensers can be placed at the sides of hallways, or, if the hallway is sufficiently wide, along the center to create a traffic divider. Units are battery powered and do not need to be located near a plug.

Dispensers that are not used often should be relocated to areas with higher than expected umbrella usage or traffic. The units will fit on any standard sized hand cart for easy transportation. As seen in our [Umbrella_final_report#Quantitative_Analysis:_Traffic_Study | analysis]], determining the distribution of units before placement is difficult.

For our sample implementation on the campus of Carnegie Mellon University, we estimate that approximately 160 dispensers will be needed. The doorways needing the most dispensers are those located in Doherty Hall, the University Center, and Porter Hall.

Failure Modes

FMEA table

Manufacturing and Production

Process

Talk about manufacturing process here. Be sure to highlight DFMA considerations.

Volume

From our analysis, we estimate that we would need the capacity to store approximately 2000 umbrellas around Carnegie Mellon's campus. Given that our dispenser stores about 12 umbrellas per unit, we would need about 160 units for campus.

There are approximately 2500 four-year universities in the U.S., with an average enrollment of about 4400 students each. This is about half of Carnegie Mellon's undergraduate and graduate enrollment total. If the number of dispensers is directly related to the number of students, the average university will need 80 units.

If we can interest just 1% of four-year universities at the start, our estimated production volume will be 2000 units up front. Additional units or replacement parts may need to be purchased later. At an average lifespan of 5 years, an additional 400 units will need to be produced annually.

Prototype History

Our design went through a number of iterations. Here are the major design prototypes.

First Prototype

Our initial prototype was designed to be a small modular unit with a simple design and low part count. The flat sides of the device allow multiple units to be placed next to each other for an umbrella distribution with multiple locations to take out and return umbrellas. The body of the device was built with wood material and painted red. The ramp on the top of the device, which was made of low-friction teflon material, moves umbrellas quickly from the receiving end to the dispensing end with no additional mechanical input from the system. Keeping the number of the device low allows the device to be reliable. The only places where the umbrellas need to be actively dealt with by the system are the input and output chutes. For the input chute, there was a latch attached to torsional spring to make sure that umbrellas cannot taken out from the receiving end once they are returned. Also, for the output chute, a turnstile was implemented to make sure that one umbrella is taken out at a time.

Second Prototype

The second prototype was modified version of the first prototype. The major change in the second prototype compared to the first design is that electrical system was implemented into the device. The electronic system is activated by card-swiping motion by users and the device dispenses umbrella by rotating the turnstile implemented at the receiving end. The motion of the motor is controlled by a microcontroller to rotate the turnstile by approximately 90 degrees angle. Also, ventilation holes were made on the sides of the device to induce drying effect of wet umbrellas by free convection. The input chute of the device was machined down to have ramp on the inlet to make it easier for users to return their umbrellas back to the system after use. A removable drip tray was added on the bottom of the device to collect the water droplets from the wet umbrellas while they are stored inside the device. For the second prototype, the actual umbrellas, specially chosen for the prototype, were used to test the function of the device.

Final prototype

Differences between our second and final prototypes.

Production differences

Differences between our final prototype and production model

Analysis

Comparison of Alternatives

In order to compare our system to current market

Advantages of our system: summary

Our umbrella distribution system offers several advantages over individual users carrying umbrellas. The improvements fall into the areas of safety and convenience.

Safety was considered from many angles in the development of the system. Control over the umbrella drying ensures that no umbrella will remain damp for too long, which could occur if the umbrella was shoved into a poorly-ventilated backpack. Users will also be in contact with the umbrella only during use, which minimizes potential exposure to microbes. More people will be using each single umbrella, but waterless hand sanitizer units, located at the end of each row of dispensers, will prevent germs from transferring from users' hands to the umbrellas.

There are other advantages that comes from not having users carry around umbrellas unnecessarily. Because each unit is located near a doorway, umbrellas will not be carried wet through the hallways, resulting in fewer wet, slick hallways. Similar effects will be seen in rooms, with less moisture on the floors where damp umbrellas are generally tossed.

The main reason that this system is attractive is its convenience. Users will no longer have to carry flimsy collapsible umbrellas, or large full-sized umbrellas. Umbrellas will be available when needed, and unobtrusive when not needed. There will be no more worrying or scrambling after forgetting an umbrella at home. Full-sized, durable umbrellas are used, and bulk purchase decreases the per-unit cost.

Quantitative Analysis: Traffic Study

Mechanical Analysis

Motivations

The physical construction of our device is relatively simple. It contains few components, and those components are already well-developed and commonly used. The size of the device is constrained by the umbrellas, and device weight is not a large concern since it will be stationary. Given this, we did not feel that a strictly mechanical analysis would provide us the insight that we need to develop a complete solution. In addition to the design of the hardware, the issue of implementing the system had to be addressed. This is where we chose to focus our analysis.

The largest issue of implementation is determining where to place the units, and how many modular units to put at each location. Traffic flow into and out of each doorway is the major determinant of this, so we decided to find out what the traffic flow was like as a function of time at the major doorways on campus. By determining the flow rate and difference in number of umbrellas at each location we can determine the number of umbrellas needed at each location for a given time, and the speed at which these umbrellas need to dry in order to be ready for reuse.

Methods

Two methods were used to investigate traffic flow at the major doorways. The first was to model our campus using a Markov simulation. This is model that uses probabilities of users moving from one location to another to estimate overall traffic flux around campus.

The second method was sitting by doorways and counting people going into and out of each doorway. Data was logged, time stamped, and analyzed later.

Findings

Our largest learning from these analyses is that it is very difficult to model traffic flow. Personally counting everyone moving through a given doorway is time-intensive. Modeling traffic flow is faster, but the number of assumptions necessary to produce a functional model may invalidate the results. Even if we could accurately model traffic flow on campus for a rainy day, the existence of the checkout system could alter traffic patterns significantly.

From observing people moving in and out of doorways, we got an order of magnitude estimation of necessary umbrella capacity at the major locations. Our analysis shows that it will take a capacity of approximately 200 to 300 umbrellas at the major doorways on campus.

The simplest solution to solve the modeling and estimation inaccuracies is to overpopulate the system initially, and then move units around as needed to meet demand. A full analysis to get a better estimate of traffic flow would be to difficult, if not impossible, to achieve, and would require many hours to realize. Overpopulation of units is simple and fast.