Staple gun numerical analysis

From DDL Wiki

This article was contributed as part of a design project for the course 24-441 Engineering Design in the spring semester of 2007 at Carnegie Mellon University.

Fundamental Equations

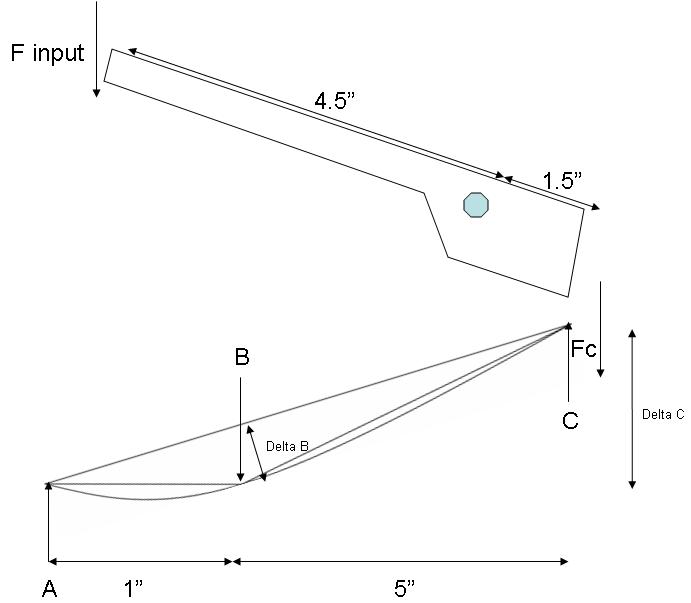

For this analysis we assumed that the lever where force is applied is perfectly rigid. We also assumed that the bar under going bending is linearly elastic. We have simplified the motion between the handle and the bar, ignoring friction and assuming point loads. We have also assumed a point load at the furthest point of the handle.

We used three point bending to simulate the bar, this model was rotated by an angle Theta so that the middle and far end points stay stationary and only point C undergoes any displacement. It's behavior is given by the following equations. Where point C is the end of the bar which bends, Theta is the angle formed by CAB, Delta C is the distance the end is displaced, Fc is the force at the point C. All calculations are done in pounds and inches.

Fa=5*Fc

Fb = 6*Fc

Delta B = Fb(3L^2 – 4a^2)/48*EI

Theta = Arctan(Delta B)+Arctan(Delta B / 5)

D = Sqrt(Delta B ^2 + 25)

Delta C = D* sin(Theta)

Numerical Anaylsis

We have been given the displacement, 3/4", the length of the bar, 6", the length of AB, 1", the length of the handle to the fulcrum, 4.5", and the length from the fulcrum to the point C.

Delta C = 3/4"

Delta C = Sqrt((0.01443*Fc)^2 +25) * sin(Arctan(0.01443*Fc))+Arctan((0.01443*Fc))

Fc = 8.730 lb

F input = 4.5/1.5 * F c

F input = 3.24 lb

Return to the main Staple gun page.